In industrial wastewater treatment or chemical processing, pH is a critical parameter, yet it is often the hardest to maintain. Operators frequently face issues like sensor drift, sluggish response times, and short lifespans (often less than 3 months).

Here is the hard truth: 80% of pH sensor failures are not due to quality, but due to wrong selection.

Whether you are dealing with oily wastewater, strong acids, or high-temperature fermentation, choosing the right specific electrode is key. This guide provides 6 expert steps to help you select the perfect industrial pH sensor and save thousands in maintenance costs.practical and industrial pH sensor selection guidelines for engineers.

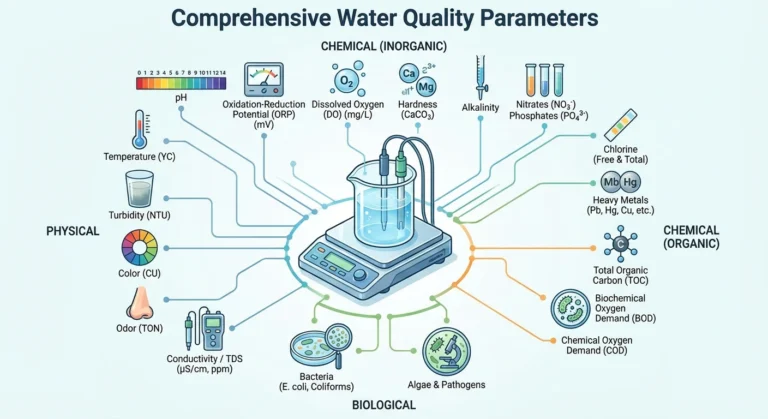

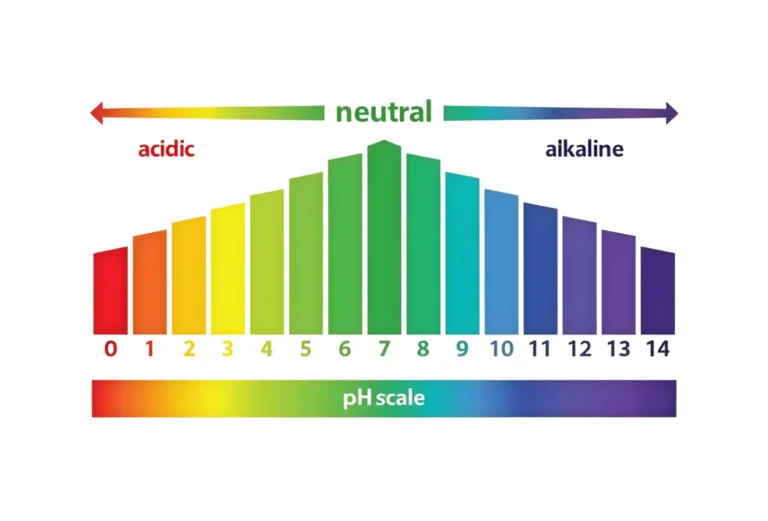

What is a pH sensor?

In simple terms, a pH electrode (often called a pH sensor or probe) is an electrochemical sensor that measures the acidity or alkalinity of a liquid.

Think of a pH electrode as a battery.

While a normal battery has a fixed voltage, a pH electrode generates a tiny millivolt (mV) signal that changes depending on the pH of the water it is dipped in. According to the Nernst equation, typically, for every change of 1 pH unit, the voltage changes by approximately 59.16 mV (at 25°C).

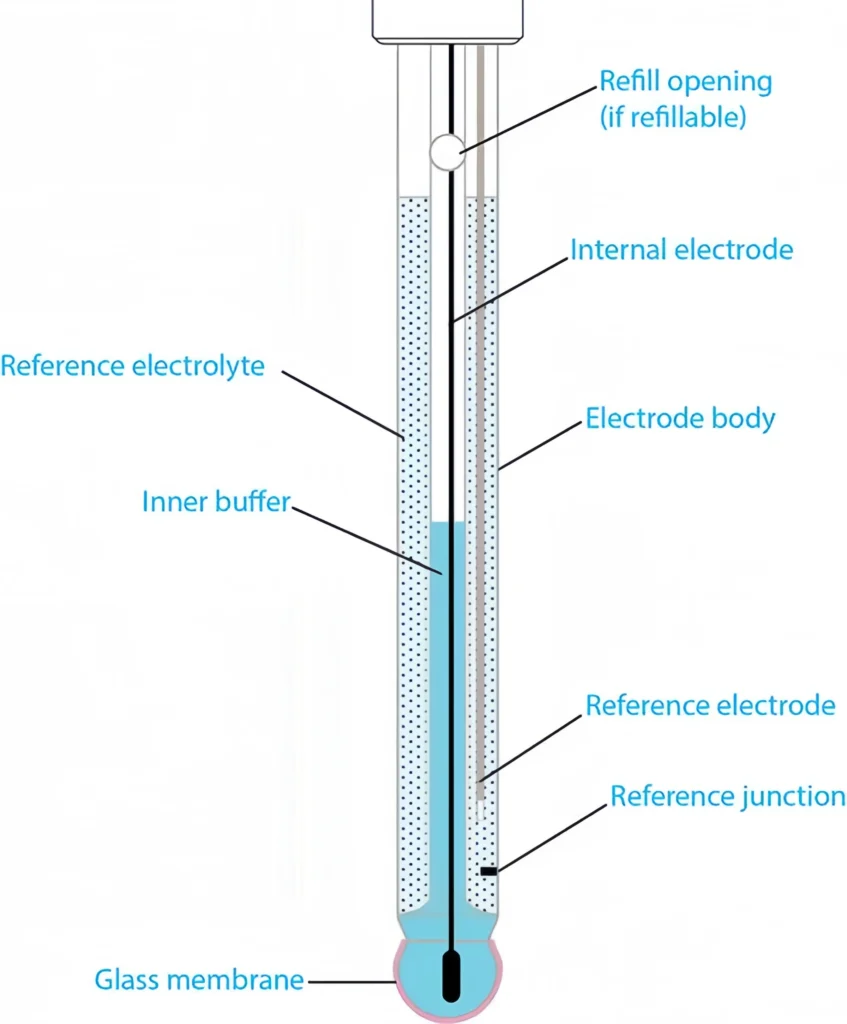

Most modern industrial sensors are “Combination Electrodes,” meaning they combine two essential parts into one body:

- The Measuring Electrode (The “Nose”):

This is the visible glass bulb at the bottom. It is made of special pH-sensitive glass that interacts with hydrogen ions in the water. - The Reference Electrode (The “Baseline”):

Usually made of a Silver/Silver Chloride (Ag/AgCl) wire floating in an internal electrolyte (KCL solution). It provides a stable, constant voltage against which the measuring electrode is compared. - The Liquid Junction (The “Bridge”):

This is a porous material (ceramic, PTFE, or wood) that allows the internal electrolyte to slowly flow out and make electrical contact with the wastewater.

💡 Why Choose Sino Inst?

Unlike fragile laboratory sensors, industrial pH sensors are built with reinforced bodies and specialized junctions to withstand harsh environments.While generic sensors often fail due to junction clogging or glass breakage, Sino Inst industrial pH sensors are built with reinforced PTFE junctions and impact-resistant glass formulations. We customize the internal structure to ensure your readings stay stable, even in the toughest wastewater or chemical applications.

Don’t risk your process with a fragile probe. [Explore Sino Inst’s Durable glass or plastic-shell pH Sensor Series].

The durability and drift of pH electrodes essentially depend on: glass film+reference structure+interface design+installation conditions.

Now that you understand the basics, let’s dive into why industrial pH sensors fail so often—and how to avoid it with the right selection.”

Why are pH electrodes so prone to breakage in industrial settings?

The most common problem with industrial sensors is interface blockage.

No matter what you see:

- Numerical drift

- Slow response

- Calibration is unstable

- It’s broken in three months

90% of them are due to the use of sensor structures that are not suitable for the medium.

So, the correct selection=extending lifespan x improving reliability x reducing maintenance costs.

Types of Industrial pH Sensors

You usually just need to think about two things when choosing the correct sensor: the material and how easy it is to keep.

By the material of the body: glass vs. plastic

- Glass Body (The Lab Standard): Best for hot and very corrosive chemicals. They are the fastest to respond, yet they are also weak.

- Best for: chemical processing, reaction tanks, and sterilizing at high temperatures.

- Recommended: [Sino Inst Glass Sensor Series]

- Plastic Body (Epoxy / PPS / PEEK): Made to be almost impossible to break. The tough casing protects the sensor bulb from damage, making it the best choice for wastewater, however it normally only works up to 80°C.

- Best for: treating wastewater, using in the field, and swimming pools.

- Suggested: [Sino Inst Durable Plastic pH Sensors]

By Electrolyte: Gel or Liquid

- Gel-Filled (Sealed): These units don’t need to be refilled and don’t need any maintenance. Great for internet monitoring when you want to “install it and forget it.”

- Liquid-Filled (Refillable): Lets you add more electrolyte, which makes the sensor last longer. Best for clean water or precise lab work.

The Defense Line by Junction

Double Junction: A must-have for effluent from factories. It has two barriers that keep poisons (sulfides/metals) from breaking the reference wire.

PTFE Junction: A big ring with holes in it that doesn’t become clogged up in unclean, greasy water.

Complete selection process for industrial pH electrodes (6 steps in total)

Step 1: Confirm the measurement medium (core)

First, ask yourself three questions:

- Is the medium clean or dirty?

- Clean: drinking water, circulating water

- Ordinary: Chemical process liquid

- Dirty: wastewater, papermaking, printing and dyeing, electroplating

- Is the medium corrosive (strong acid/strong alkali/solvent)?

- Does it contain oil, suspended solids, high solids, or high salt?

Determine the type of sensor foundation based on the properties of the medium:

| Medium | Recommended electrode type |

|---|---|

| Clean water | Standard glass+ceramic interface,such as GRT1030. |

| Ordinary liquid | gel electrolyte+reinforced junction,such as GRT1120WE. |

| Sewage/Mud | Open/Large Area PTFE Interface,such as KPT561FW. |

| Strong acid and strong alkali | Special glass film+Double salt bridge,such as HF1120. |

| Food and Pharmaceutical | ISFET or High Temperature Glass (Sanitary Type),such as GRT1020PD. |

Step 2: Choose the appropriate “junction structure”

The junction determines whether the sensor is blocked, which is the key to its lifespan.

| Junction Type | Characteristics | Applicable scenarios |

|---|---|---|

| Ceramics | High sensitivity | Cleaning medium |

| Porous ceramics | slightly better pollution prevention | ordinary industry |

| Large area PTFE | Strong anti clogging | Wastewater, fiber, grease |

| Open interface | Least likely to block | High pollution, high viscosity |

| Double salt bridge | Resistant to ion pollution | High salt and highly corrosive media |

Step 3: Determine the type of glass film/sensing element

Determine the type of glass film based on temperature and acidity/alkalinity:

| Operating conditions | Glass type |

|---|---|

| Room temperature (0-60 ° C) | Standard glass |

| High temperature (60-90 ° C) | Medium temperature glass |

| Strong alkali pH>12 | High pH specialized glass |

| 121 ° C disinfection | High temperature glass/ISFET non glass |

| Food hygiene requirements | ISFET |

Step 4: Confirm the structure of the electrode electrolyte

Electrolyte affects stability and maintenance cycle.

| Electrolyte type | Advantages | Scenarios |

|---|---|---|

| Gel type | Low maintenance | Most industrial applications |

| Rechargeable | High stability, long service life | Chemical, strong corrosion |

| Pressure reference | Strongest anti pollution | High pollution and high-pressure scenarios |

Step 5: Determine temperature, pressure, and chemical resistance requirements

- Temperature: Is there CIP/SIP available? Is there any temperature fluctuation?

- Pressure: normal pressure? High pressure vessel? Do we need a pressurized reference?

- Material compatibility: Choose PEEK/PPS/316L/glass shell.

Temperature and corrosiveness are the main causes of glass film rupture and reference failure

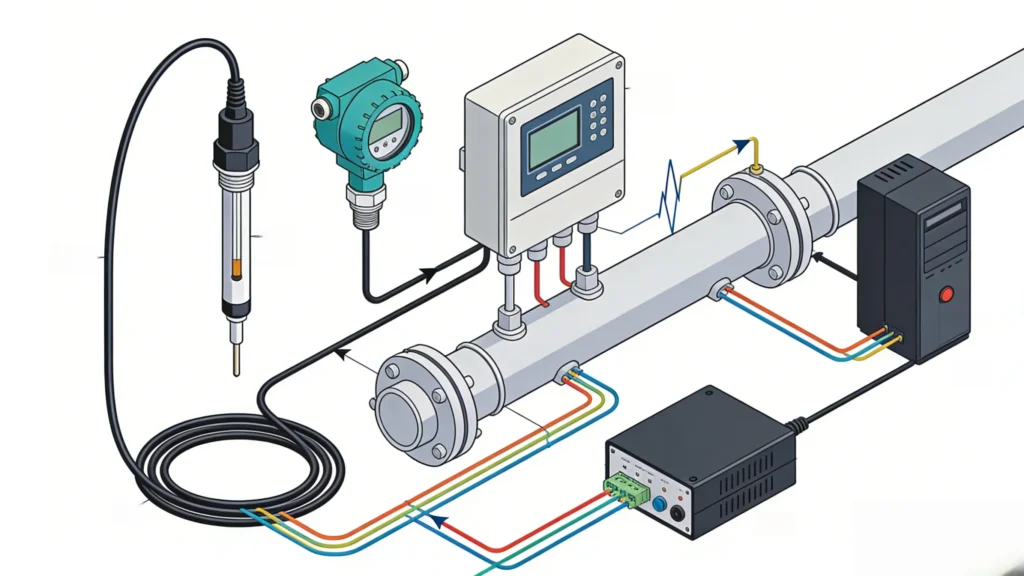

Step 6: Determine the installation method

The lifespan of an electrode is 50% determined by the installation method.

Optional installation methods:

- Immersion type (tanks or reaction tanks): Install these at a 45° angle and 10 to 15 centimeters below the surface of the liquid to avoid bubble traps and deposits.

- Type of flow cell (pipeline on-line): Make sure the flow rate is between 0.1 and 0.5 m/s. If it’s too fast, the glass film will wear down, and if it’s too slow, it will clog.

- Sanitary Clamp (Pharmaceutical/Food): Pick a tri-clamp that is smooth so bacteria can’t grow in the sides.

- Automatic cleaning or self-purging: This is necessary for sewage, oil, or papermaking. It needs to be cleaned with 5% HCl or an enzyme solution and should not be cleaned with anything that scratches the surface.

Installation should avoid bubbles, deposits, and strong eddies, otherwise the electrode will quickly fail.

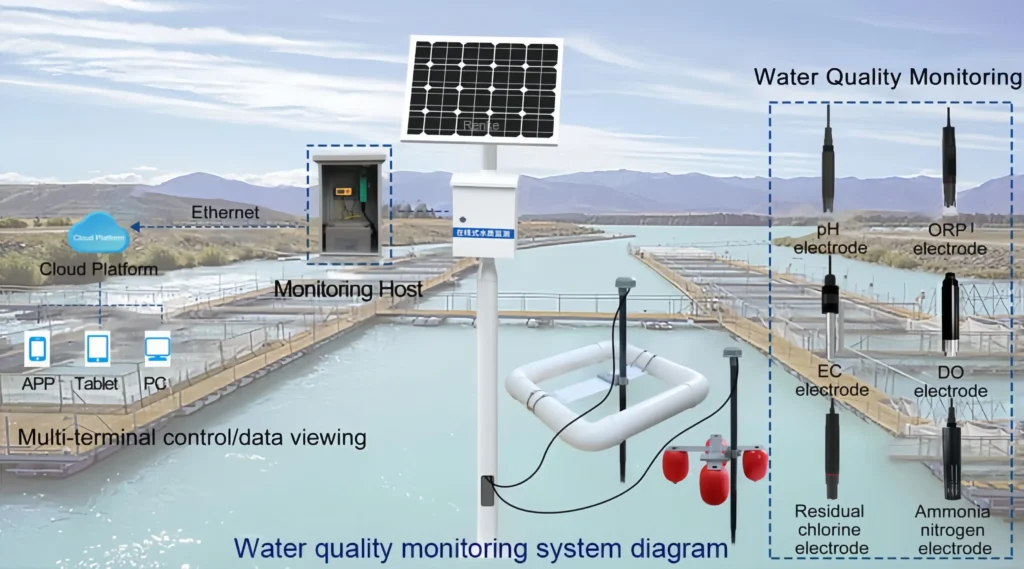

Typical Selection Guidelines for Different Industries (Quickly Match)

To make it even easier, here’s a quick-reference guide for common industries—match your scenario to the core requirements.

| Industry | Core Selection Points | Recommended Model Features |

|---|---|---|

| Municipal/Industrial Wastewater | Anti-clogging + easy maintenance | Open junction + automatic cleaning |

| Chemical Process | Corrosion resistance + stability | Special glass + double salt bridge + PEEK shell |

| Food/Pharmaceutical | Sanitary + high-temp resistance | ISFET/high-temp glass + sanitary tri-clamp |

| Electroplating/Papermaking/Dyeing | High salt + anti-pollution | Double salt bridge + large-area PTFE junction |

Common errors in industrial sites (avoid pitfalls)

Even the best sensor won’t last if misused. Below are the most common on-site mistakes to avoid.

- ❌Replacing industrial electrodes with laboratory electrodes

- ❌Electrode installation upwards causes bubble trapping

- ❌Ignore temperature compensation

- ❌Choosing the wrong junction structure

- ❌Improper cleaning leads to damage to the glass film

How to extend the lifespan of pH electrodes (maintenance points)

- ✅Can’t dry it

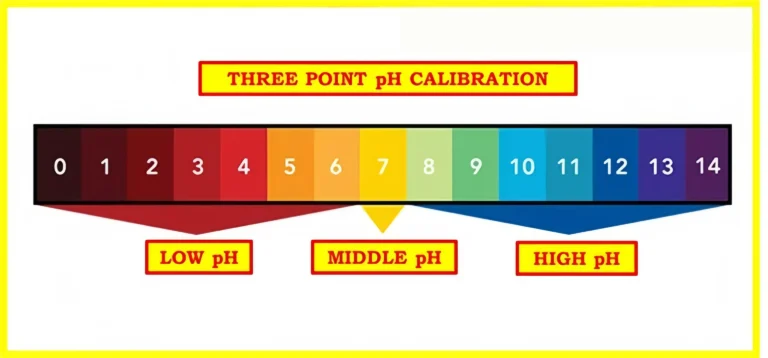

- ✅Regular calibration (2-4 weeks)

- ✅Choosing the correct cleaning method (acid washing/alkali washing/enzyme washing)

- ✅Avoid sudden temperature changes

- ✅Regularly check if the interface is blocked

FAQ

Choosing the proper industrial pH electrode for the job can save you from having to go to the site a few times, change the probe a few times, and deal with hassles from drifting and clogging.

Please feel free to get in touch with Sino Inst at any time if you are choosing a specific project or want to learn more about industrial pH electrode solutions that last a long time and don’t get clogged. We can give you specific quotes and suggestions based on the type of media you have, the temperature, and the conditions of the installation.

Related Products

Glass Sensor

Plastic-Shell Sensor

More Resources

-

The 10 Best Digital carbon monoxide detectors 2026: An Industrial Guide

Carbon monoxide (CO) remains one of the most hazardous invisible threats in industrial, commercial, and residential environments. Colorless, odorless, and tasteless, it requires…

-

Can gas detectors detect multiple gases simultaneously?

In the complex and often hazardous world of industrial manufacturing, petrochemical processing, and confined space operations, ensuring the safety of personnel is the…

-

Surface Water vs Groundwater: A Comprehensive Guide to Water Quality

In the domains of environmental engineering and industrial water management, knowing the basic differences between surface water vs groundwater is not just an academic…

-

What is the pH of Reverse Osmosis Water? The Complete Science Guide (2026)

If you have ever been curious about ‘what is the pH of reverse osmosis water?’, you are not alone. This is one of…

-

The Top 8 Portable CO Detector for Car Use

Introduction: The Silent Threat in Automotive Cabins Carbon monoxide (CO) is a colorless, odorless, and highly toxic gas generated by the incomplete combustion…

-

6 Best Mass Flow Controller for Liquids: An Expert Technology Guide

In modern industrial automation, pharmaceutical manufacturing, and semiconductor fabrication, the precise control of fluid dynamics is a fundamental requirement. Relying on outdated volumetric…

.png)