To keep an eye on water quality that you can trust, you need to start with precise conductivity-based readings.

We sell industrial-grade sensors and analyzers at Sino-Inst for:

- Conductivity

- Resistivity

- TDS (Total Dissolved Solids)

- Salinity

Made for treating wastewater, getting clean water, desalination, and industrial processes

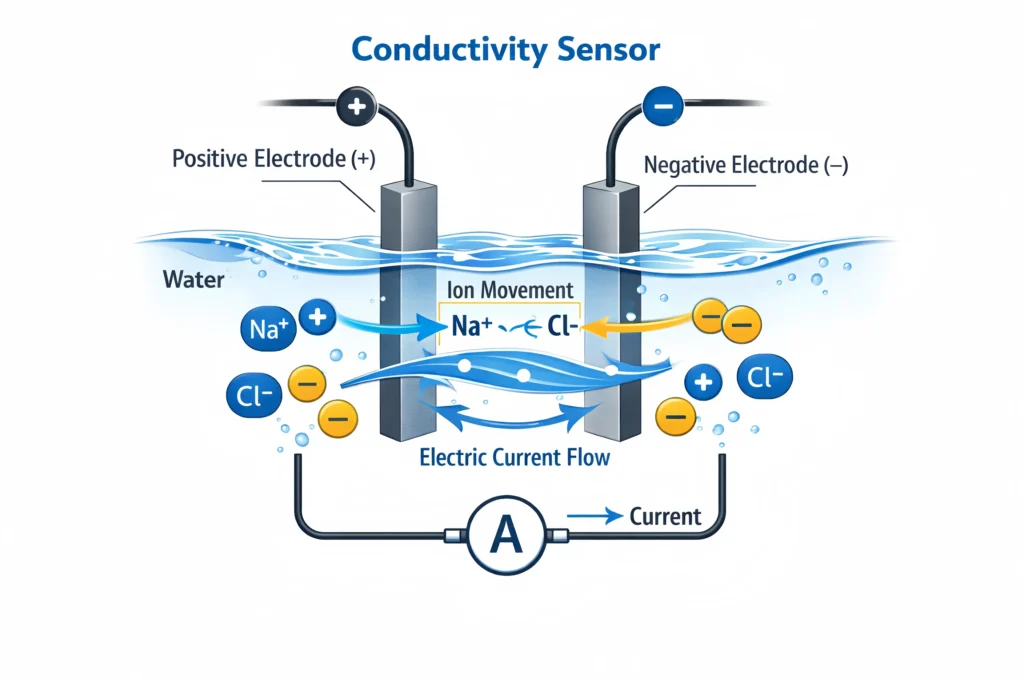

Why Conductivity-Based Measurement Matters

Unlike single-parameter monitoring, conductivity-based measurements provide

a fast and reliable way to evaluate ionic concentration, contamination level,

and process stability in real time.

That’s why conductivity, resistivity, TDS, and salinity sensors are often used

together as a complete water quality control solution.

Product classification

Online conductivity/resistivity/temperature/salinity/TDS controller

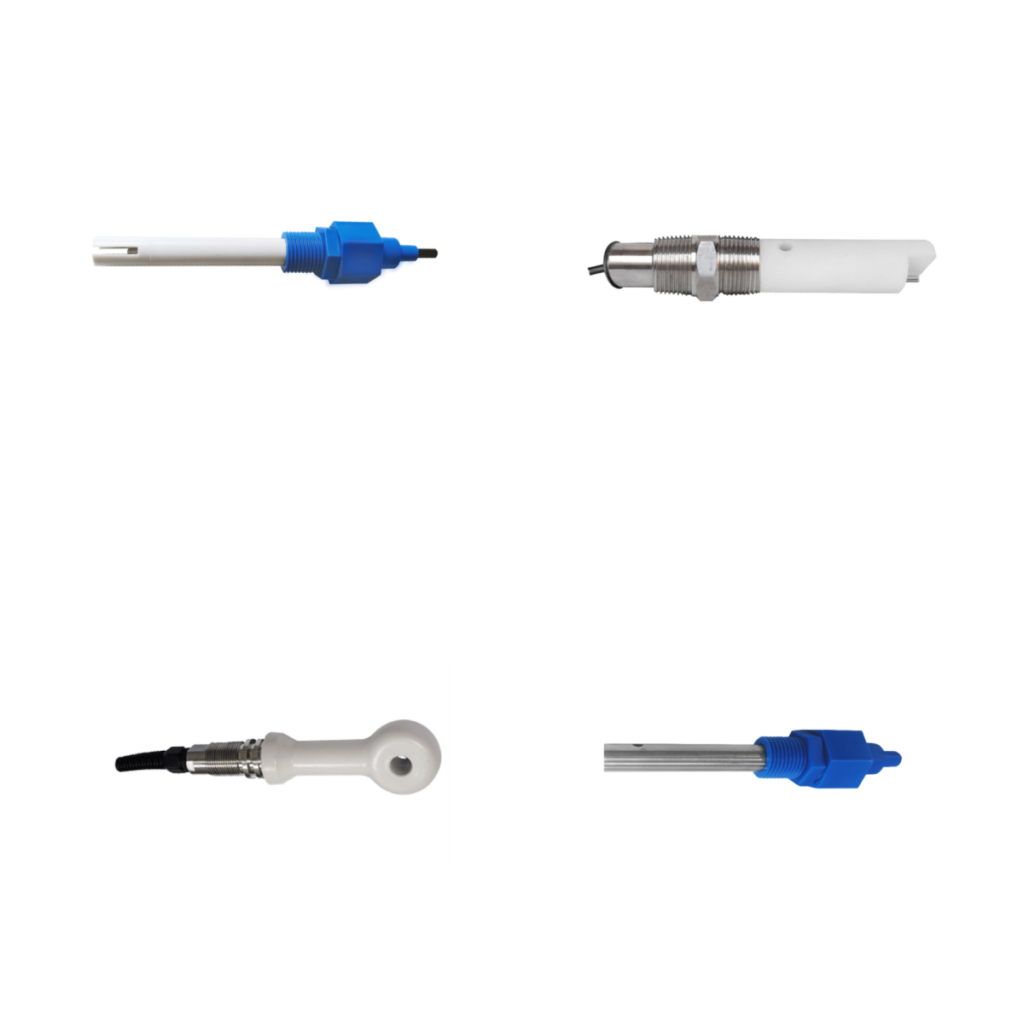

Online conductivity/resistivity electrode

Electromagnetic conductivity meter

EC20-SA1 CONDUCTIVITY CONTROLLER

Laboratory conductivity/resistivity meter

DDS-307A CONDUCTIVITY CONTROLLER

Portable conductivity/resistivity meter

DDB-305A conductivity controller

Core parameters and detection significance

Core parameters

- Conductivity is the ability of water to carry electrical current. It is measured in μ S/cm or mS/cm and shows how many ions are in the water and how well they can move about. The more ions there are, the higher the conductivity number. This is a simple way to tell how clean or dirty water is.

- Resistance is the opposite of electrical conductivity and is measured in M Ω· cm. The higher the value, the better the water quality (with fewer ions). It is an important part of keeping an eye on purity during the process of making ultrapure water and pure water.

- TDS (Total Dissolved Solids) is the total amount of solid substances, including salts and minerals, that are dissolved in water. It is measured in mg/L. It shows how much dissolved substance pollution is in the water quality, and it is commonly used to check the quality of drinking water, sewage, and industrial water.

- Salinity is the amount of dissolved salts in water, measured in parts per thousand (ppt). The major application is to keep an eye on the salt levels in seawater, aquaculture water, and water used to make salt chemicals, which has an effect on the ecology and production processes of water.

Core significance of detection

(2) Core significance of detection

The four major parameters are interrelated and complementary. Through synchronous detection by the Conductivity Controller, key information such as water quality purity, pollution type, and ion concentration can be quickly determined, providing accurate basis for water quality standard determination, production process regulation, and scientific research data collection, avoiding the limitations of single parameter detection. Difference and Relationship of Parameters

Conductivity vs Resistivity vs TDS vs Salinity

| Parameter | Unit | Typical Application |

|---|---|---|

| Conductivity | µS/cm, mS/cm | Wastewater, cooling water, industrial process |

| Resistivity | MΩ·cm | RO, EDI, ultrapure water |

| TDS | ppm / mg/L | Drinking water, process water |

| Salinity | ppt / PSU | Seawater, aquaculture, desalination |

Key Insight:

One conductivity sensor can be used to calculate TDS or Salinty through compensation algorithms,while Resistivity is simply the inverse value for low-conductivity water.

Typical Industrial Applications

- Municipal & industrial wastewater treatment

- RO / EDI / ultrapure water systems

- Cooling tower blowdown control

- Chemical process concentration monitoring

- Desalination & seawater intake

- Aquaculture & fish farming

How to Choose the Right Sensor?

- Choose conductivity for general ionic concentration

- Choose resistivity for high-purity water

- Choose TDS for simplified water quality indication

- Choose salinity for seawater and brine processes

Always consider:

- Temperature range

- Installation method (inline / submersible)

- Chemical compatibility

Common Selection Mistakes to Avoid

- Using TDS instead of conductivity for process control

- Choosing low-range sensors for high-salinity applications

- Ignoring temperature compensation

- Using resistivity sensors in contaminated water

- Selecting the wrong installation method (inline vs submersible)

If any of these sound familiar, our engineers can help you re-evaluate your setup.

Why Choose Process-Inst?

- Industrial-grade sensor design

- Stable measurement and long service life

- OEM & customization support

- Fast technical response

Conclusion: Change Measurement into Control

Not just numbers, conductivity, resistivity, TDS, and salinity are important signs of how well a process is working, how good a product is, and how safe a system is.

- This entails picking the correct sensor:

- Readings that are more stable

- Less time spent on maintenance

- Less expensive to replace over time

FAQ

We at Process-Inst don’t think that one solution works for everyone.

Our engineers work closely with customers to make sure that the design, material, and measuring range of the sensor are right for real-world industrial settings, not just what they think would work in a lab.

We can help you choose a long-term solution that works well for monitoring wastewater discharge, RO/DI systems, or operations with a lot of salt.

👉 Are you not sure which TDS or conductivity sensor is right for your needs?

Tell us about your working conditions, and our technical team will send you a free selection recommendation within 24 hours.

.png)