The Plastic Shell pH/ORP Electrode Series is designed to work in places where glass sensors don’t work. These sensors are made with high-impact polymer bodies (PPS or Polycarbonate), so they last a long time and don’t react badly with chemicals. They are also very cheap.

Our plastic-body electrodes are made to withstand physical impact and harsh flow conditions, unlike fragile glass probes. This makes them the standard choice for monitoring the environment, aquaculture, and wastewater treatment. We have the right sensor for you, whether you need a simple one for a pool or a heavy-duty PPS probe for industrial waste water.

Product classification

What is a pH electrode?

The “Heart” of Water Quality Analysis

pH sensor are the main parts of water quality monitoring systems, just like the heart pumps blood. Use the difference in potential between two liquids whose pH levels are not the same. This potential difference is made when two liquids touch both sides of a pH element, which is a thin film of glass. How much voltage is made depends on how acidic or basic the solution is.

The pH element lets H+ ions pass through when it is immersed in an acidic solution, which creates a positive potential. In alkaline environments, on the other hand, H+ions will move away from the probe, which will make the potential negative. This potential difference is measured by the pH meter, which turns it into a pH reading.

How Does a pH Sensor Work?

Think of the pH sensor as a small battery to understand how it works.

In fact, a normal industrial pH combination sensor has two separate sensors built into one housing:

The measuring electrode, also known as the sensing bulb:

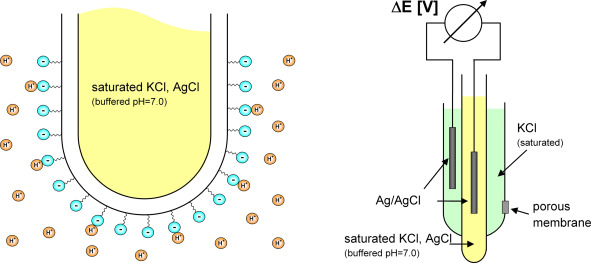

The sensor’s tip is made of a special glass membrane that can tell the difference in pH. A gel layer appears on the surface of glass when it is submerged in water. An electric potential (Voltage A) is made when the quantity of hydrogen ions in the liquid outside is different from that in the buffer inside.

The constant, or reference electrode, is:

This is the “ground” or “baseline” of a circuit. It gives off a steady voltage (Voltage B), which is generally made by a silver/silver chloride (Ag/AgCl) wire in a KCl electrolyte solution.

The Potential Difference (The Nernst Equation)

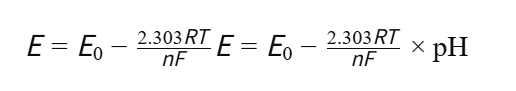

The pH meter measures the voltage difference between these two sensors. According to the Nernst Equation, at 25°C, for every 1 unit change in pH, the voltage changes by approximately 59.16 mV.

- pH 7 (Neutral): The measuring electrode and reference electrode are balanced, producing 0 mV.

- pH < 7 (Acidic): Generates a positive millivolt signal (e.g., pH 4 ≈ +177 mV).

- pH > 7 (Alkaline): Generates a negative millivolt signal (e.g., pH 10 ≈ -177 mV).

Note: This “Slope” (59.16 mV/pH) is why calibration is vital. As an sensor ages, this slope degrades (e.g., drops to 55 mV/pH). Your controller uses calibration to learn the current slope and calculate accurate readings.

pH electrode type

What is a Plastic-Shell Electrode? (vs. Glass Electrode)

Plastic shell pH/ORP sensor is an industrial sensor used to measure water pH and ORP. Using corrosion-resistant plastic casing to protect sensing elements and reference systems.

Key differences from glass sensors:

| Feature | Plastic-Shell Electrode | Glass Electrode |

|---|---|---|

| Housing Material | PP/PTFE/PVDF | Borosilicate glass |

| Corrosion Resistance | Excellent (resists most acids/alkalis) | Poor (susceptible to hydrofluoric acid, strong alkalis) |

| Fragility | Non-fragile, durable for on-site use | Fragile, high breakage risk in complex environments |

| Weight & Installation | Lightweight, easy to mount | Heavy, requires careful handling during installation |

| Cost | Economical, low maintenance cost | Higher cost, frequent replacement needed |

| Suitable Scenarios | General wastewater, chemical processes, water supply (non-extreme media) | High-precision laboratory, ultra-pure water, non-corrosive media |

How to Choose the Right Plastic-Shell Sensor?

Selecting the optimal plastic-shell sensor requires matching scenario characteristics, controller compatibility, and medium properties. Follow this guide:

By Measurement Parameter

- pH-only monitoring: Choose pH-specific models (GRT1020series).

- ORP-only monitoring: Select ORP-specific models .

- Dual pH/ORP monitoring: Pick dual-function models (GRT1030) to pair with switchable controllers (e.g., BT-280, A11PR).

By Medium Characteristics

- High suspended solids/solids content: Choose models with anti-fouling diaphragms and SS316 brackets (GRT1020JP/JW,GRT1090) to avoid clogging.

- Moderate corrosion (weak acids/alkalis): PP housing models (GRT1020/GRT1030) balance performance and cost.

- High-temperature media (≤80℃): PVDF housing models (GRT1020T) ensure stable sensing.

By Controller Compatibility

Ensure the electrode’s connector matches your controller:

- S8/VP connectors: Compatible with BT-280, A10PR, A11PR series.

- Threaded connectors: Pair with RP-3000 dual-channel controllers for pipeline installation.

- Cable length: Standard 5m; for distances >10m, select signal-amplified extended cables to avoid signal attenuation.

Application Scenarios

Wastewater from cities and factories

Because of how complex wastewater is, sensors that don’t get clogged up quickly are needed. For tracking aeration tanks and effluent, our PPS body electrodes with PTFE junctions are the best on the market.

Fish farming and aquaculture

Stable pH levels are important for fish health. Since plastic sensors don’t break into sharp pieces of glass, they are safe to use and can last for a long time in salt water or fresh water ponds.

Spas and swimming pools

Our inexpensive PC body ORP and pH probes give accurate readings to keep water clean and balanced in automatic chlorination systems.

Hydroponics and farming

Nutrient treatments can damage things. Plastic sensors that last a long time make sure that the fertilizer is mixed correctly without breaking during tank upkeep.

.png)