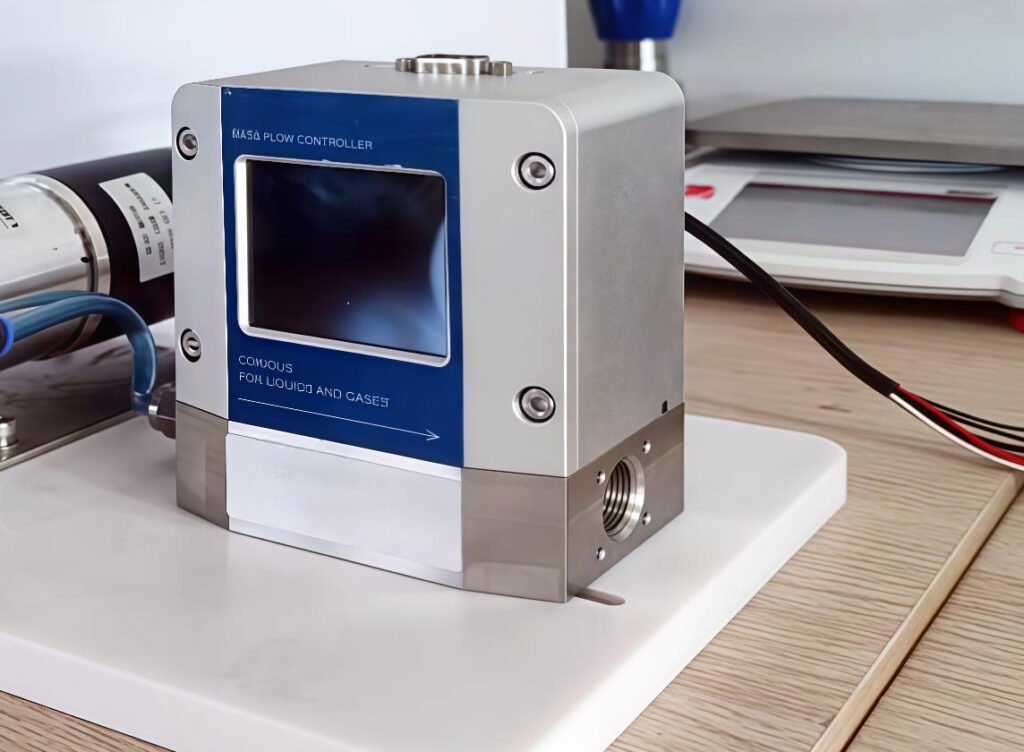

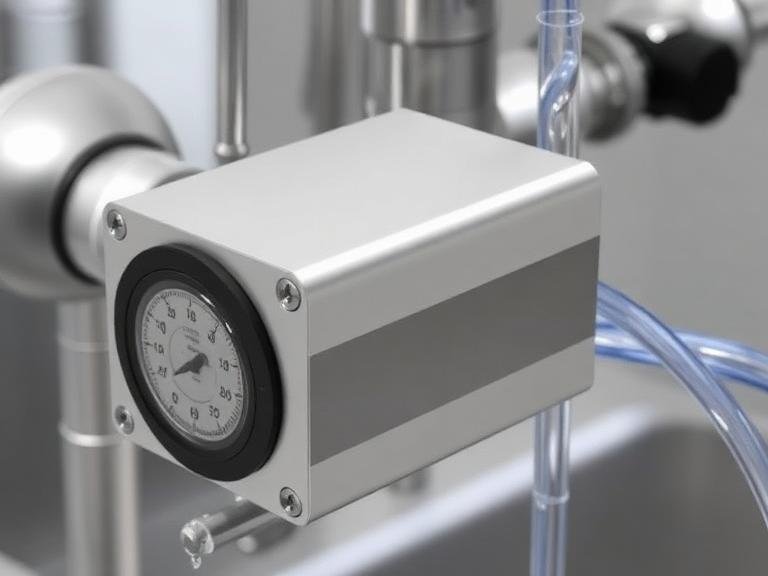

The SI-10FA Analog Mass Flow Controller/Meter consists of a mass flow sensor, laminar flow stratification components, a flow controller regulating valve, and an amplification control circuit. It utilizes the thermal conductivity distribution effect, where the flowing fluid transfers heat, altering the temperature distribution of the measuring capillary wall.

The SI-10FA measures the mass flow rate of gas using the temperature difference calorimetry principle before and after capillary heat transfer, unaffected by temperature or pressure. The flow signal measured by the sensor is amplified and compared with a set voltage. The difference is used to drive the regulating valve, creating a closed-loop control to ensure the flow rate through the channel equals the set flow rate.

★★★★★

Features

Specifications

Low Range:

| Technical Specifications | SI-10FA-LC Mass Flow Controller | SI-10FA-LM Mass Flow Meter |

| Range | 5SCCM ~ 30SLM | |

| Accuracy | ±1.0%F.S | |

| Temperature: ±1℃ | ||

| Linearity | ±0.5%F.S | |

| Repeatability | ±0.2%F.S | |

| Response Time | <2s | <1.5s |

| Analog Output | 0 ~ 5V、4 ~ 20mA | |

| Power Supply | ±15VDC,24VDC | |

| Operating Temperature | 0 ~ 50℃ | |

| Operating Pressure | Operating differential pressure: 0.05 ~ 0.5MPa | Operating pressure drop: <30 kPa |

| Maximum Pressure Rating | 3MPa/10MPa | |

| Electrical Connection | DB9 | |

| Leak Rate | 1×10^-9 SCCSHe | |

| Temperature Coefficient | ±0.015%F.S/℃ | |

| Base Material | Stainless steel | |

| Seal Material | Fluororubber, neoprene rubber, nitrile rubber | |

| Connection | φ3, φ6, 1/8”, 1/4” | |

Mid-range:

| Technical Specifications | SI-10FA-MC Mass Flow Controller | SI-10FA-MM Mass Flow Meter |

| Range | 30SLM-150SLM | |

| Accuracy | ±1.0%F.S | |

| Temperature: ±1℃ | ||

| Linearity | ±0.5%F.S | |

| Repeatability | ±0.2%F.S | |

| Response Time | <2s | <1.5s |

| Analog Output | 0 ~ 5V、4-20mA | |

| Power Supply | ±15VDC,24VDC | |

| Operating Temperature | 0 ~ 50℃ | |

| Operating Pressure | Operating differential pressure: 0.05 ~ 0.5MPa | Operating pressure drop: <30 kPa |

| Maximum Pressure Rating | 3MPa/10MPa | |

| Electrical Connection | DB9 | |

| Leak Rate | 1×10^-9SCCSHe | |

| Temperature Coefficient | ±0.015%F.S/℃ | |

| Base Material | Stainless steel | |

| Seal Material | Fluororubber, neoprene rubber, nitrile rubber | |

| Connection | φ8, φ10, φ12 | |

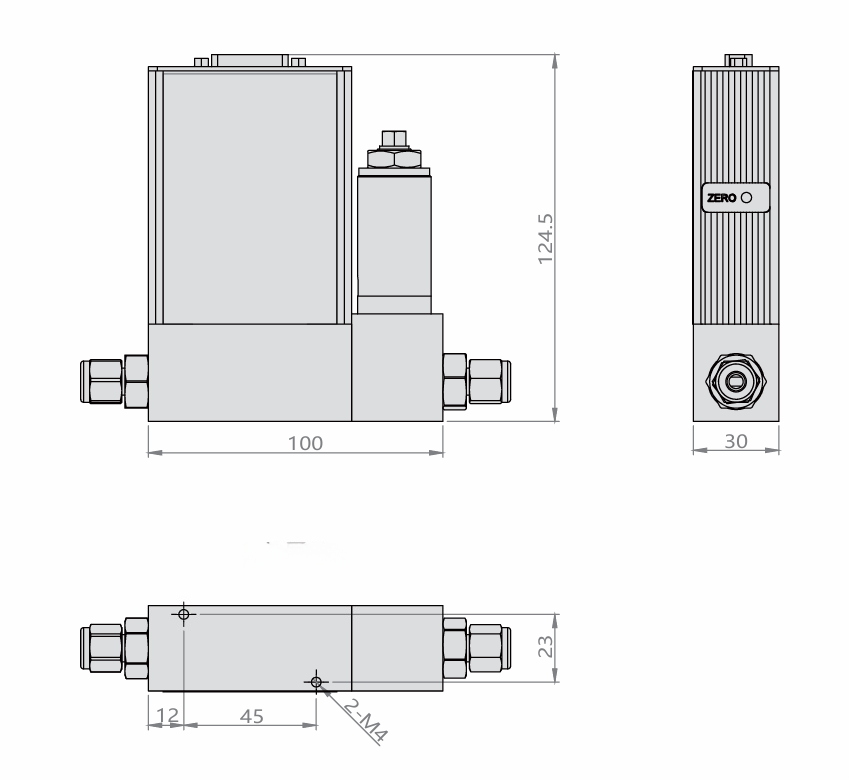

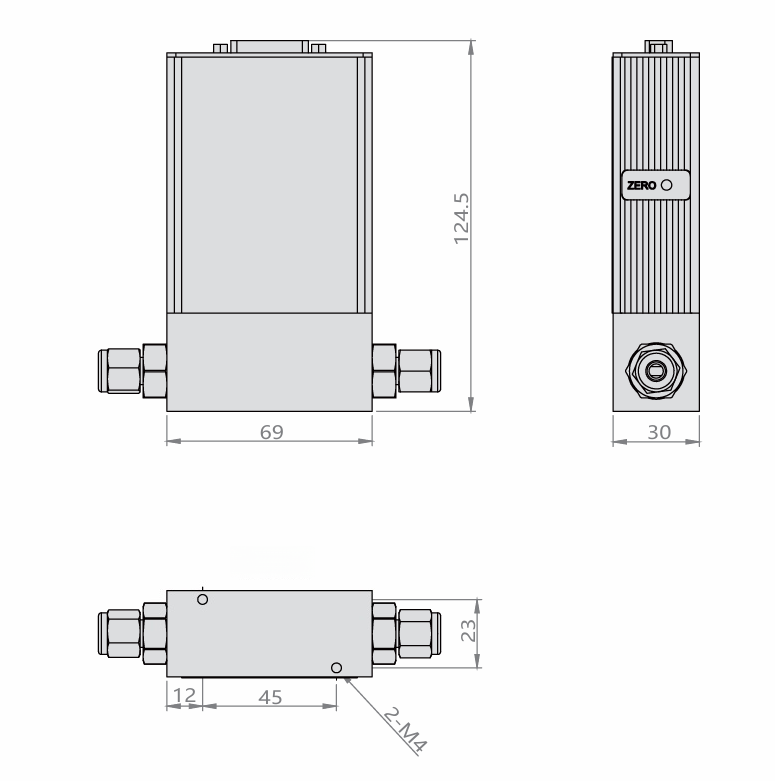

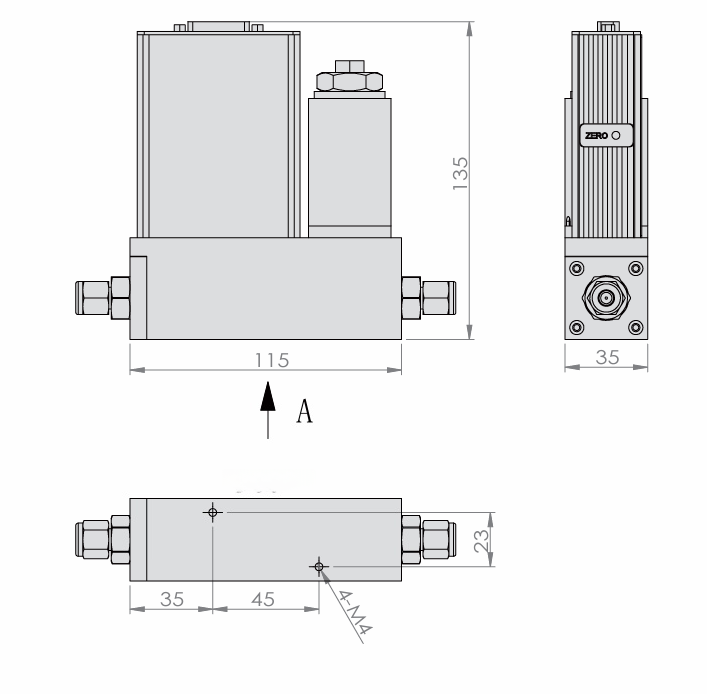

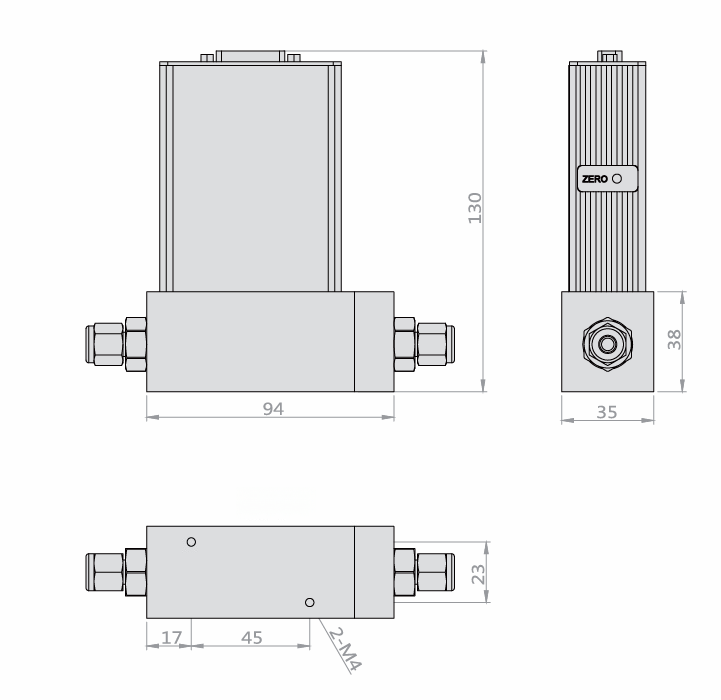

Dimensions

SI-10FA-LC Mass Flow Controller

SI-10FA-LM Mass Flow Meter Dimensions

SI-10FA-LM Mass Flow Meter Dimensions SI-10FA-MC Mass Flow Controller Dimensions

SI-10FA-MC Mass Flow Controller Dimensions SI-10FA-MM Mass Flow Meter Dimensions

SI-10FA-MM Mass Flow Meter Dimensions

Order Guide

| Serial Number | SI-10FA-L (Low Range) SI-10FA-M (Medium Range) |

| Product Type | 【C】Mass Flow Controller 【M】Mass Flow Meter |

| Pressure Rating Range | 【M】3MPa 【Z】10MPa (Flowmeter only) |

| Flow Rate Range | 【005C】5SCCM 【010C】10SCCM 【020C】20SCCM 【030C】30SCCM 【050C】50SCCM 【100C】100SCCM 【200C】200SCCM 【300C】300SCCM 【500C】500SCCM 【001L】1SLM 【002L】2SLM 【003L】3SLM 【005L】5SLM 【010L】10SLM 【020L】20SLM 【030L】30SLM 【050L】50SLM 【100L】100SLM 【150L】150SLM |

| Measured Medium | See density reference table for details |

| Flow Input Signal | 【A1】0~5VDC 【A2】4~20mA |

| Output Signal | 【B1】0~5VDC 【B2】4~20mA |

| Supply Voltage | 【5】±15VDC 【4】24VDC |

| Seal Material | 【V】Fluoroelastomer 【T】Nitrile Rubber 【N】Neoprene 【Y】Other |

| Connection Type | 【A】φ3 【B】φ6 【C】φ8 【D】φ10 【E】φ12 【F】1/8“” 【G】1/4“” 【Y】Other (Contact manufacturer) |

| Selection Example | SI-10FA-M M M 020L 007 A1 B1 5 V C |

Can the Flow Range of an Analog Mass Flow Controller/Meter Be Changed?

- Changing the flow range of an MFC usually involves replacing critical components (such as the distributor valve orifice) and recalibrating the flow range precisely. Therefore, user-mandated flow range changes are generally not recommended and are quite difficult.

- Flow range changes should be performed by the manufacturer or their authorized service centers to ensure accuracy and reliability. If the user believes the initial flow range selection is inappropriate, it is recommended to contact the supplier or original manufacturer for professional support.

- When changing the flow range, the compatibility of the flow display device must be considered simultaneously:

- If the flow display is in percentage (%) mode, the display device generally does not require adjustment.

- If the flow display is in absolute units (such as SCCM, SLM) mode, the display device usually needs to be adjusted accordingly to match the new flow range.

- Alternatively, the display device can be left unadjusted, and the displayed flow reading can be multiplied by a calibrated correction factor to obtain the actual flow value.

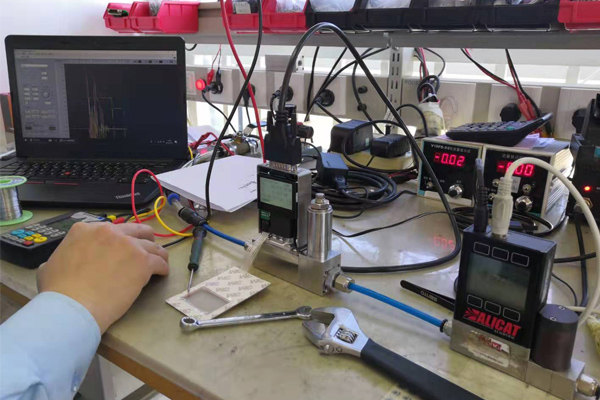

Connecting Analog Mass Flow Controller/Meter to a Computer

A computer can be directly connected to an MFC (Mass Flow Controller), or it can be connected to an MFC via a flow meter. For analog gas mass flow controllers, a conversion board is generally required on the computer. The analog-to-digital converter receives the flow measurement value, and the digital-to-analog converter outputs the flow setpoint signal. These conversion boards are readily available in the industrial control product market.

If the gas mass flow controller is directly connected to a computer, the user needs to provide the power supply (which must have strong anti-interference capabilities).

Technical Support

Analog Mass Flow Controller/Meter Price

The market price of Analog Mass Flow Controllers/Meters is primarily influenced by their core performance indicators, especially flow control range (scale) and control accuracy. Generally, devices with higher accuracy requirements have correspondingly higher manufacturing costs and technical complexity, resulting in higher market prices.

Users should comprehensively evaluate their accuracy needs based on their actual application scenarios when selecting a model. Not all applications require the highest accuracy MFC; choosing a model that meets process requirements and offers a suitable cost-performance ratio is a more rational approach.

With technological advancements and accumulated application experience, the application of MFCs in various technology-intensive fields such as industrial automation, semiconductor manufacturing, life sciences, and new energy is continuously expanding.

Buyer’s Guide: 7 Critical Factors for Choosing an Online Gas Detector

What is a Combustible Gas Detector? And 5-Step Selection Guide

5 Essential Factors for Choosing Multi Gas Detectors

7 Critical Gas Detector Calibration Errors to Avoid: An Expert Guide

How Gas Detectors Work: 4 Key Sensor Types

An Expert 7-Point Checklist for Industrial Gas Detection Systems

Buyer’s Guide for Ammonia Gas Monitor

Proven Solutions for the 5 Critical Health Dangers of Ammonia Leaks

Buyer’s Guide: 7 Critical Checks for Selecting a Chlorine Gas Detector

7 Critical Mistakes in Gas Sampling System Design: A Practical Checklist

CO2 Sensor vs. VOC Sensor: What’s the Difference?

Expert Guide: How a Photoionization Detector Works

Guide to Connecting a Thermal Mass Flow Controller to a PLC

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

8 Best Mass Flow Controller Manufacturers

How Does a thermal mass flow controller working principle?

6 Best carbon monoxide detector Test 2025

Top 7 portable combustion analyzer Tested

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

6 Types of Industrial Oxygen Sensors

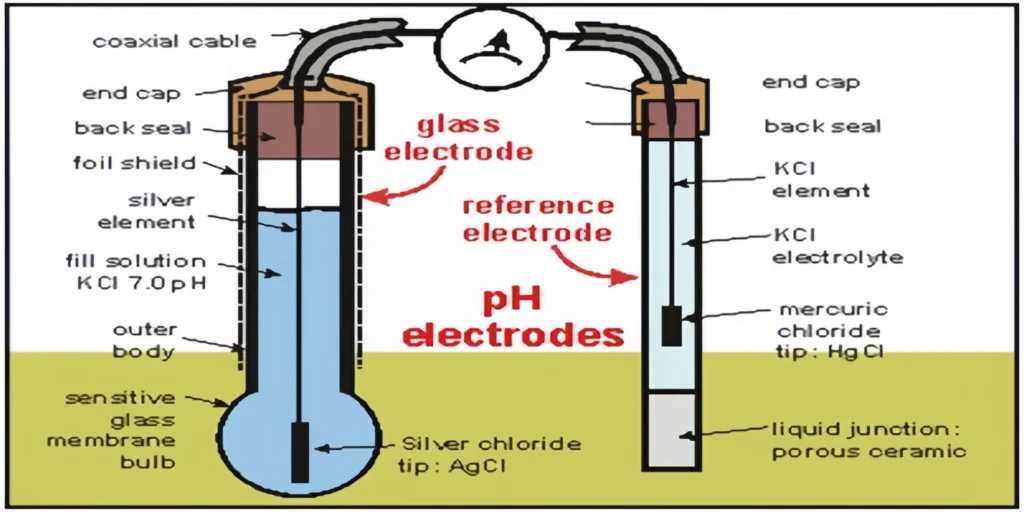

What Is pH in Water? A Complete Guide to Understanding (2026)

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

10 Best carbon monoxide monitor for industrial use 2025

5 Best carbon monoxide detector for garage

Top 8 gas detectors for confined spaces in 2025

Top 6 Mass Flow Controller Manufacturers in the USA

Top 10 Mass Flow Controllers for Gases 2025

7 Best Gas Analyzer Manufacturers in 2025

7 Best 4 Gas Monitors for Industrial Use

Top 8 Portable Gas Detectors for Confined Spaces

8 Best Gas Detector Alarms 2025

Top 5 Heavy-Duty Plastic pH Meter Sensors for Wastewater (2026)

6 Best Portable Carbon Monoxide Detector for Travel: Stay Safe in 2025

Carbon Monoxide Detector Chirping: Decoding the 5 Most Critical Scenarios

How to Choose the Right pH Sensor: 6 Expert Tips

What is photoionization detector? and use

9 Best Fixed Gas Detector Manufacturers 2026

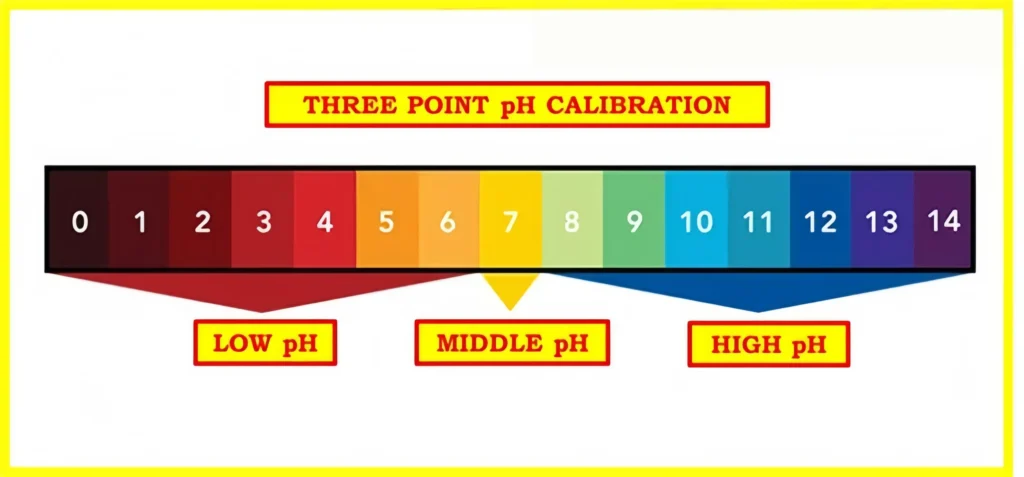

How to Calibrate pH Meter: A Step-by-Step Guide for Accurate Readings

8 Best portable multi gas detector 2026

9 Best handheld gas leak detectors 2026

Top 6 Electrochemical Gas Sensor Manufacturers 2026

7 best carbon monoxide detector on phone 2026

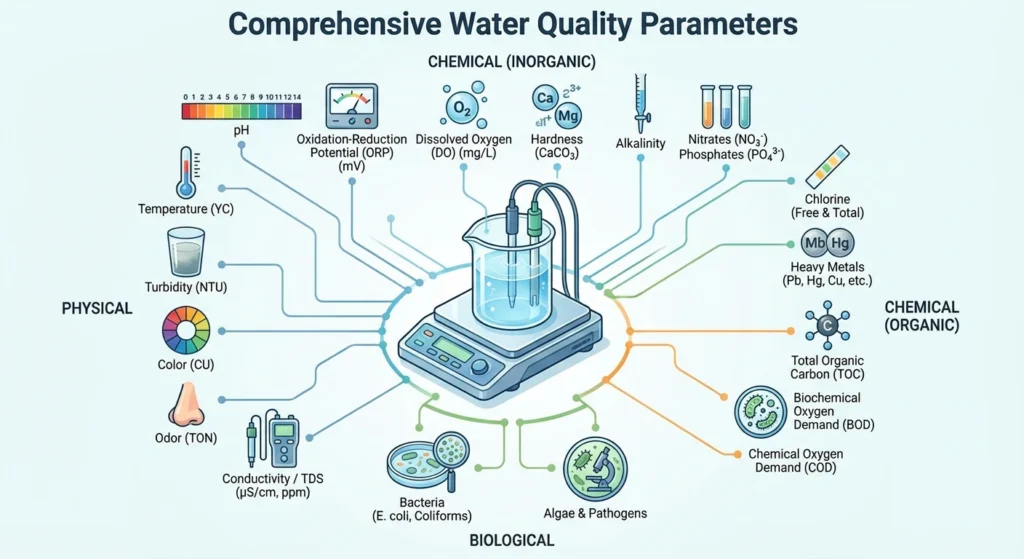

Mastering Water Quality Parameters: Professional Guide To Control(2026)

6 Best Fixed Gas Detection System 2026: Industrial Safety and Precision

10 Best Gas Line Leak Detectors 2026: Comprehensive Safety Guide

8 Best portable gas monitoring equipments 2026

10 Best Methane Gas Detectors 2026

Safety First: Why is My Carbon Monoxide Alarm Beeping Every 30 Seconds?

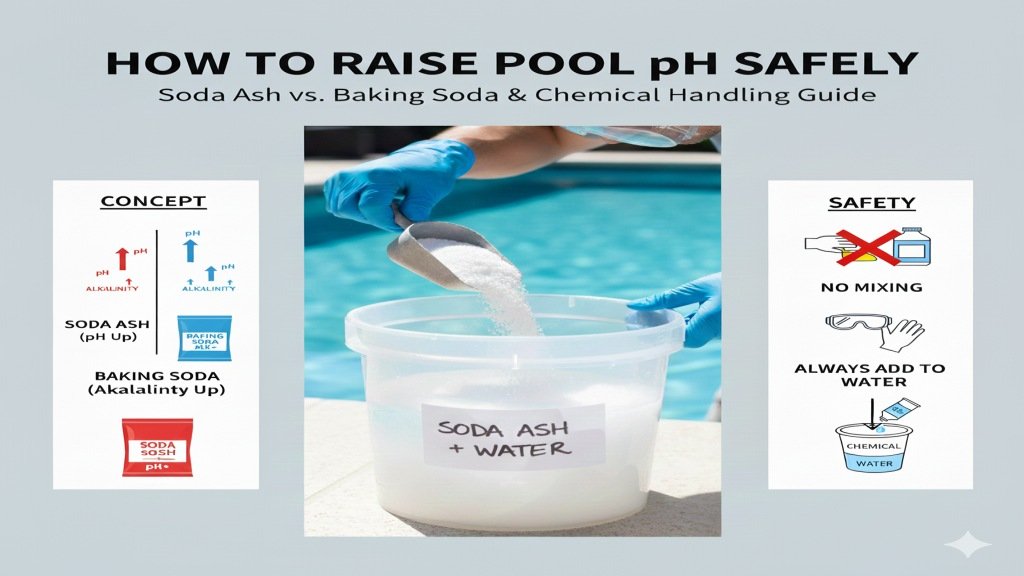

How to Raise pH in Pool: The Chemical Guide & The Automated Solution

The Shocking Truth About the pH of Distilled Water: Why It’s Not 7.0

Carbon Monoxide Levels Chart 2026 Update: Safety Guidelines and PPM Limits

6 Most Reliable Multi Gas Detectors for Industrial Use (2026 Guide)

Industrial Gases List 2026: The Ultimate Guide to Types and Usage

5 Critical Differences: Is Distilled Water the Same as Purified Water?

Mastering Safety: How to Check Gas Level in Confined Space?

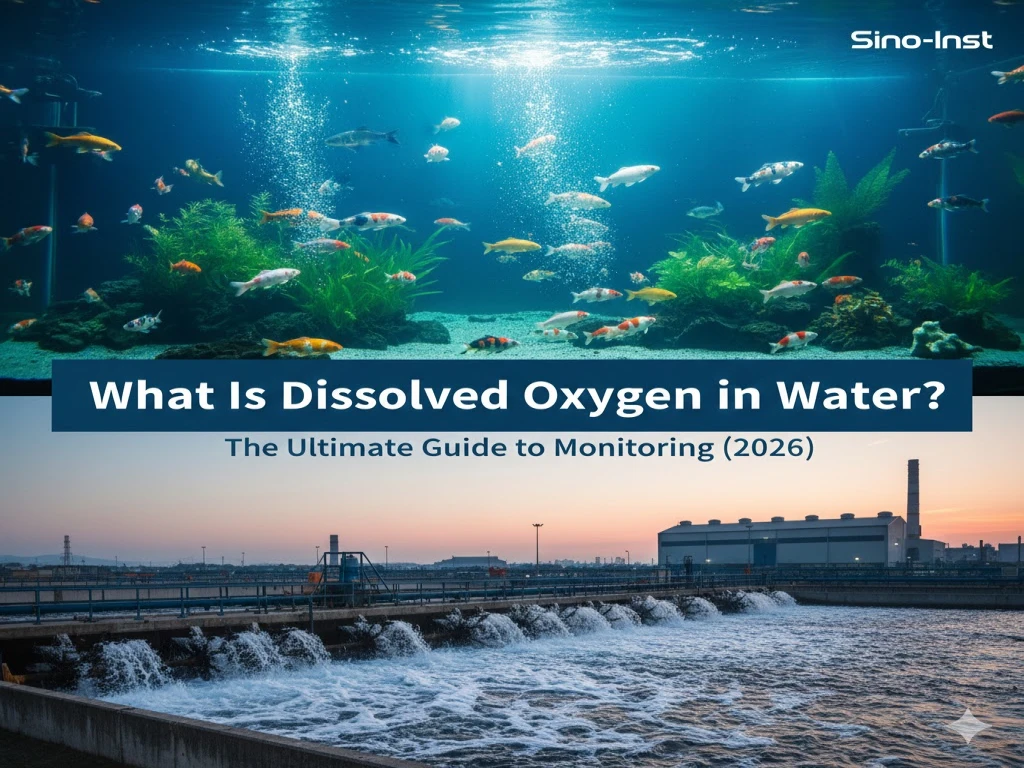

What Is Dissolved Oxygen in Water? The Ultimate Guide to Monitoring(2026)

9 Best Personal Gas Monitoring Devices 2026

Choosing a pH Meter for Water:The Professional Guide to(2026)

How Do I Get My Carbon Monoxide Detector to Stop Chirping? (2026 Guide)

How Do You Test for Helium?

Test Water for pH: 5 Fatal Mistakes You Must Avoid

What is a Combustion Analyzer Used For?

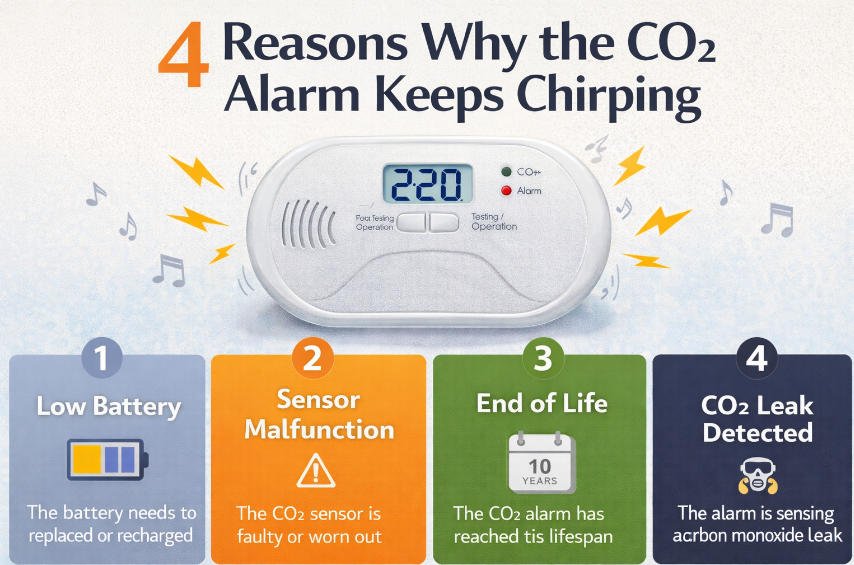

4 Reasons Why the CO2 Alarm Keeps Chirping

5 Best Place to Put a Carbon Monoxide Detector

The Ultimate Guide to Portable Dissolved Oxygen Meters (2026)

6 Best Portable Smoke Detector and Carbon Monoxide Detector for Travel in 2026

5 Methods to Detect a Gas Leak Myself 2026

Alkalinity Low In Pool? The “Silent Killer” of Your Pool Liner

7 Best Gas Detectors for Home Inspectors Tested: 2025 Review

What Does Muriatic Acid Do for a Pool?(2026)

9 Best VOC Detectors for 3D Printing Safety (2026 Guide)

5 Expert Tips to Put an Explosive Gas Detector for Maximum Safety

Total Chlorine vs Free Chlorine: The Complete Industrial Monitoring Guide (2026)

5 Kinds of Detector Detects Gas Leaks: Expert Selection Guide

Is It Safe to Drink Purified Water? Practical Guide to Making a Healthy Choice.

How to Get Rid of Chlorine in Water — The Complete Science-Backed Guide (2026)

The Definitive Guide to the Mass Flow Controller Working Principle

Does Water Conduct Electricity? The Complete Science Guide (2026)

6 Best Mass Flow Controller for Liquids: An Expert Technology Guide

The Top 8 Portable CO Detector for Car Use

What is the pH of Reverse Osmosis Water? The Complete Science Guide (2026)

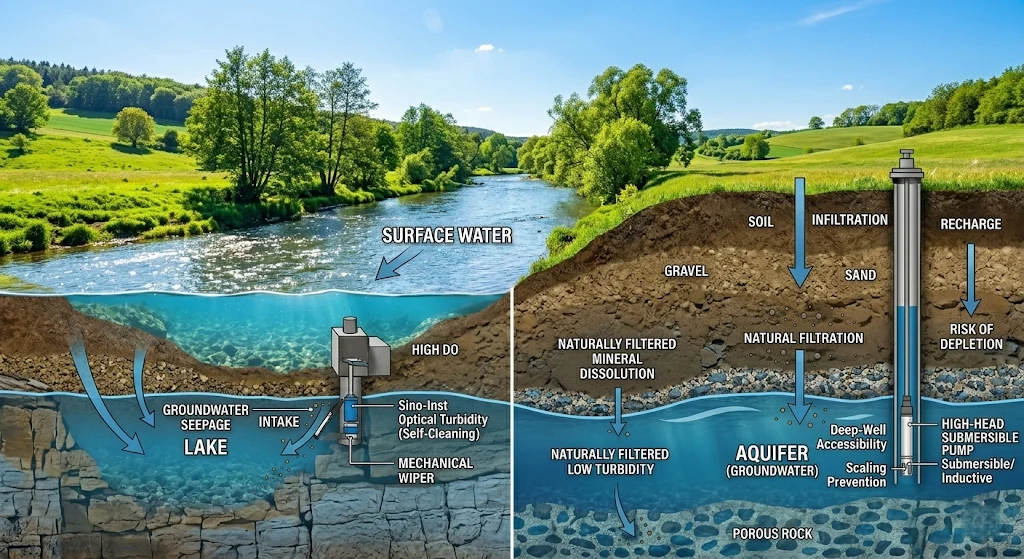

Surface Water vs Groundwater: A Comprehensive Guide to Water Quality

Can gas detectors detect multiple gases simultaneously?

The 10 Best Digital carbon monoxide detectors 2026: An Industrial Guide

Sino-Inst is a professional manufacturer and supplier of Analog Mass Flow Controllers/Meters. Our high-precision mass flow controllers offer broad gas compatibility (nearly 100 gases) and a response time of less than 200ms. They exhibit excellent adaptability to mixed gases, meeting the performance requirements of most mixed gas systems.

We also provide compact gas distribution boxes and cabinets with integrated displays and digital control methods such as Modbus. Customization of various parameters and OEM/ODM services are supported. Please feel free to contact our sales engineers!

Request a Quote

.png)