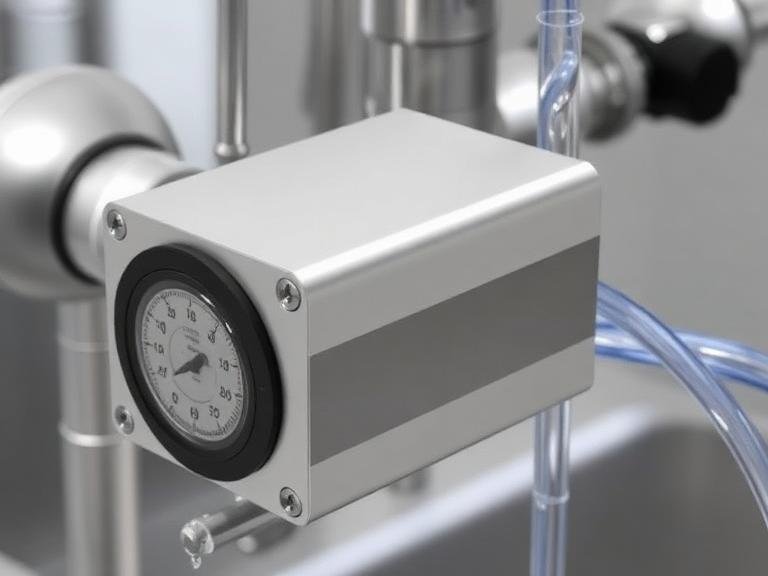

Mass Flow Controllers/Flow Meters are used for the precise measurement and control of gas or liquid mass flow rates. Also known as MFC/MFM, they not only function as mass flow meters but, more importantly, can automatically control gas/liquid flow rates. This ensures stable fluid transmission at a preset flow rate in industrial processes, scientific experiments, or environmental monitoring. Even with system pressure fluctuations or changes in ambient temperature, the flow rate remains constant at the set value. They offer high measurement accuracy, good sensitivity, and high reliability, and are widely used in various industries.

Sino-Inst’s fluid mass measurement and control products are available in three technology types: thermal, differential pressure, and Coriolis. All three types utilize proven and mature technologies, ensuring high accuracy and reliability for Sino-Inst products. To further ensure accuracy, internally compensated laminar differential pressure technology, intelligent sensor technology, and digital display technology are also widely used in the product series.

Featured Thermal Mass Flow Controllers/Meters

Featured DP Mass Flow Controllers/Meters

Featured Coriolis Flow Controllers/Meters

Display and Control System

Benefits

Mass Flow Controllers/Flow Meters Technology

Thermal Principle

Thermal mass flow controllers/meters measure fluid mass flow rate based on the thermal principle of measuring cooling effects. They are characterized by high stability and high measurement accuracy.

Differential Pressure Principle

Differential pressure mass flow meters/controllers measure fluid mass flow rate by measuring the pressure difference across a throttling element. They are characterized by fast measurement and control response.

Coriolis Principle

Coriolis flow meters/controllers measure fluid mass flow rate based on the principle of variable phase shift caused by the Coriolis force. They are characterized by being unaffected by fluid characteristics and achieving extremely high accuracy.

Featured Applications

Mass flow controllers/meters have wide applications in industrial production and scientific research.

In semiconductor manufacturing, mass flow controllers/meters are used to precisely control gas flow rates in processes such as etching and deposition, ensuring product quality.

In chemical production, mass flow controllers/meters are used to control the flow rates of reactant gases, ensuring the stability and safety of chemical reactions.

In the biopharmaceutical field, mass flow controllers/meters are used to regulate gas flow rates in pharmaceutical equipment, ensuring the stability of the pharmaceutical process.

Furthermore, mass flow controllers/meters also play an important role in environmental monitoring, food processing, analytical instruments, and many other fields.

What Is a Thermal Mass Flow Meter?

A thermal mass flow meter (TMF) is an instrument used to measure the mass flow rate of gases. It primarily measures fluid flow rate by utilizing the temperature field changes generated when a fluid flows through a pipe heated by an external heat source, or by the relationship between the energy required for the fluid’s temperature to rise to a certain value when heated and the fluid’s mass. Thermal mass flow meters are characterized by low pressure loss, wide flow range, high accuracy, high repeatability, and high reliability.

What is a mass flow controller?

A mass flow controller is a device that accurately measures and controls the flow rate of a fluid (gas or liquid).

How do mass flow controllers work?

Mass flow controllers, based on advanced sensor technology and control algorithms, monitor fluid flow rate in real time and compare it with a setpoint. They then automatically adjust valve openings to maintain the target flow rate.

Specifically, a flow controller typically consists of a sensor, a controller, and an actuator (such as a proportional valve). The sensor measures the fluid flow rate. The controller, based on the difference between the sensor’s feedback signal and the setpoint, uses a control algorithm to calculate the appropriate actuator adjustment, thus precisely controlling the fluid flow rate. This closed-loop control system ensures the stability and accuracy of the flow rate.

What is the difference between MFC and MFM?

A Mass Flow Meter (MFM) primarily measures real-time flow rate (also called instantaneous flow rate) and cumulative flow rate.

A Mass Flow Controller (MFC) primarily controls instantaneous flow rate. The user sets the desired flow rate, and the MFC automatically maintains the flow rate at the setpoint. It can also provide cumulative flow rate.

How to calibrate a mass flow controller?

Standard Commissioning Procedure

Power-on Preheating: After powering on, the equipment needs to preheat for 30 minutes to ensure stability. During preheating, check if the screen display is normal.

Zero-point Calibration:

- Without gas supply, adjust the zero point through the operating interface or an external zeroing mechanism.

- Ensure the pipeline is full of medium and the flow has completely stopped before zeroing. Repeat this operation until the zero-point fluctuation range is ≤0.1 kg/min.

- Parameter Setting: Set the target flow rate, gas type, flow range, and other parameters through the operating interface or accompanying software.

- Gas Supply Test: Slowly open the inlet valve and observe whether the flow display is stable. If the fluctuation exceeds ±1%, check the gas path sealing or adjust the PID parameters.

- Performance Verification: Use a standard flow meter (such as a soap film flow meter) for comparative testing. The error should be within ±1.5%.

Standard Calibration Method

- System Connection: Use a standard instrument with an accuracy 3-10 times higher than the device being calibrated, along with auxiliary pressure gauges, temperature sensors, etc., to build a calibration device.

- Leak test: After pressurization, use a leak-detecting fluid or pressure holding method to check for airtightness and ensure no leakage.

- Multi-point calibration: Select at least 5 calibration points (e.g., 10%, 25%, 50%, 75%, 100% of the range) and adjust the flow rate in ascending and descending order.

- Repeatability test: Repeat the measurement 3-5 times at the 50% range point and calculate the standard deviation.

- Parameter correction: If the deviation exceeds the tolerance, correct it through hardware adjustment or software parameters (e.g., K coefficient, PID parameters).

With the increasing level of industrial automation, many production processes are placing higher demands on the accuracy of flow measurement. Mass flow meters/mass flow controllers are widely used due to their ability to accurately measure and control the mass flow rate of fluids.

Whether in industrial production or in laboratories, Sino-Inst’s mass flow controllers and mass flow meters play a vital role. We offer a series of Mass Flow Controllers/Meters for both analog and digital signals. We also support product customization, especially for special operating conditions such as high temperature, low temperature, high pressure, small flow range, large flow range, and low differential pressure.

Our Sino-Inst products are CE certified for safety and compliance with EU laws, meeting EU legal requirements and allowing them to enter the EU market.

We have also obtained ISO 9001 international quality management certification, giving us international market reputation and competitiveness.

Request a Quote

More Resources

-

The 10 Best Digital carbon monoxide detectors 2026: An Industrial Guide

Carbon monoxide (CO) remains one of the most hazardous invisible threats in industrial, commercial, and residential environments. Colorless, odorless, and tasteless, it requires…

-

Can gas detectors detect multiple gases simultaneously?

In the complex and often hazardous world of industrial manufacturing, petrochemical processing, and confined space operations, ensuring the safety of personnel is the…

-

Surface Water vs Groundwater: A Comprehensive Guide to Water Quality

In the domains of environmental engineering and industrial water management, knowing the basic differences between surface water vs groundwater is not just an academic…

-

What is the pH of Reverse Osmosis Water? The Complete Science Guide (2026)

If you have ever been curious about ‘what is the pH of reverse osmosis water?’, you are not alone. This is one of…

-

The Top 8 Portable CO Detector for Car Use

Introduction: The Silent Threat in Automotive Cabins Carbon monoxide (CO) is a colorless, odorless, and highly toxic gas generated by the incomplete combustion…

-

6 Best Mass Flow Controller for Liquids: An Expert Technology Guide

In modern industrial automation, pharmaceutical manufacturing, and semiconductor fabrication, the precise control of fluid dynamics is a fundamental requirement. Relying on outdated volumetric…

.png)