The Explosion-proof Gas Sampling System is used in the gas analysis industry. Its main principle is to sample flue gas or high-temperature, high-humidity gas from the field, then cool, dehumidify, filter dust and tar, and maintain the temperature and humidity of the gas within a specific range, enabling the gas analyzer to detect concentrations correctly. The entire process is automated and requires no human intervention.

The Gas Sampling System is suitable for situations where the gas sample contains relatively little dust but is at high temperature and humidity. For situations with higher dust and tar levels, a separate tar treatment system is required. It features a 28MFlash memory for storing large amounts of data and supports exporting historical data and alarm data to a USB drive, facilitating subsequent data analysis.

★★★★★

Features

Specifications

| Sensor Type: | Electrochemical, PID photoionization, infrared, catalytic combustion, etc. |

| Gas Type: | Toxic and harmful waste gases and flue gas |

| Sampling Method | Pump-suction type |

| Explosion-proof Rating | BT4\CT6 (customizable) |

| Gas Range | Different gases have different flow ranges; (Contact customer service for more ranges) |

| Accuracy | ≤±3%FS |

| Resolution | 0.01%LEL, 0.01mg/m3, 0.01PPM, etc. |

| Repeatability | ≤±2%FS |

| Zero Drift | ≤±2%FS/6h |

| Span Drift | ≤±3%FS/6h |

| Response Time | T90≤3 S |

| Communication Method | 4-20mA/RS485 digital signal, switch control signal. |

| Operating Power | 35-40W |

| Input Power Supply | AC220V |

| Output Power Supply | DC24V |

| Operating Environment | -40℃~+70℃, ≤95%RH |

| Measurement Unit | ppm, ppb, %LEL, %VOL, mg/m3, mg/L, g/m3, ug/m3, %rh, ℃, MPa, KPa, Pa, etc. |

| Installation Method | Wall-mounted |

| Constant Temperature | 25℃: Temperature after gas treatment, settable; |

| Constant Humidity | 70%RH: Humidity after gas treatment; |

| Automatic Drainage | Automatic drainage based on site moisture levels; |

| System Heating | Optional feature to prevent pipeline freezing in extremely cold regions; |

| Sampling Distance | The standard sampling distance is 20 meters; with an optional high-power vacuum pump, the sampling distance can exceed 40 meters. If the pressure of the gas being measured is high, the sampling distance should be correspondingly longer. |

| Sampling Flow Rate | 4 liters/minute (standard). |

| Dimensions | 700mm (H) x 500mm (W) x 270mm (D) |

Explosion-proof Gas Sampling System Applications

Explosion-proof pretreatment monitoring systems are used in various high-temperature, high-humidity, or high-dust environments. High-dust environments require an automatic backflushing system; otherwise, manual maintenance and cleaning of the dust filter are necessary.

Applications include:

- Desulfurization and denitrification, natural gas pipelines;

- Flue gas emissions, boiler exhaust gas;

- Wastewater pipeline gas detection and analysis;

- Pretreatment of flammable and explosive gas samples;

- Sampling, purification, and environmental emission control of flue gas, exhaust gas, waste gas, and other gases from combustion equipment such as boilers, heating furnaces, kilns, incinerators, and coke ovens.

- Suitable for use in high-temperature or low-temperature environments such as agricultural greenhouses, laboratories, cold storage facilities, and high-temperature furnaces.

Operation of the Explosion-Proof Gas Monitoring Pretreatment System:

The system processes the sample gas according to the analyzer’s acceptable pressure, temperature, humidity, flow rate, dust content, and cleanliness level. The main tasks include:

- Sample Sampling: The sample gas is extracted from the pipeline environment using a vacuum sampling pump or a DC brushless pump;

- Dust Filtration: The gas to be tested passes through a precision dust filter before entering the sampling pipeline. For high-dust environments, an automatic backflushing system is required;

- Cooling Treatment: Cooling is achieved through the sampling probe and sampling pipeline, capable of handling gases up to 2000℃;

- Heating Function: Heating and insulation to prevent water vapor condensation and partial gas dissolution in water (optional);

- Gas-Water Separation: After the sample gas is cooled through the sampling pipeline, free water appears. The gas-water separator automatically separates the gas, water, and residual dust. Drainage;

- Molecular sieve filtration: Filters gas to ensure sensor detection;

- Secondary filtration: Optional based on site humidity, performs secondary water vapor separation;

- Signal acquisition: The sensor reacts with the gas being measured, detects the gas signal, amplifies and analyzes it; the concentration of various gas components is determined;

- Detection and analysis: Real-time detection and display of concentration, transmitting data via 4-20mA/RS485 signals, or wirelessly or via network to a remote server, environmental protection bureau, or monitoring station;

- Flow regulation: Controls the gas intake (optional).

Precautions for Use and Debugging

- Flow Control:

During system operation, the gas flow rate through the detector should be controlled to approximately 500 ml/min by adjusting the throttle valve on the flow meter and the drain pipe at the bottom of the condenser. The flow meter’s flow rate should be checked periodically to ensure it remains within the normal range.

- Analog Signal Output:

The detector has a 4-20mA analog signal. The 4-20mA output signal is already connected to the terminal block. The positive signal is marked with a wire number (mA), and the negative signal can be connected to 24V-.

- RS485 Digital Signal:

The detector’s RS485 signal is pre-installed on the terminal block. If a 7-inch touchscreen display is selected, the RS485 connection to the touchscreen’s COM2 interface is pre-installed on the terminal block. The host computer can read the concentration data from the touchscreen. See the protocol description for communication protocol details.

- Default Condenser Temperature Setting: 4℃.

- Regular manual maintenance and cleaning of the dust filter is required to prevent dust from clogging the air passages. Clean, wash, or replace the filter. Filter element specifications: Length 75 * Outer diameter 30 * Inner diameter 20. PE polymer filter element, ceramic filter element, and PTFE filter element are all acceptable.

- Regularly check the detector in the pretreatment system and perform zero-point and concentration calibration.

Technical Support

Buyer’s Guide: 7 Critical Checks for Selecting a Chlorine Gas Detector

Proven Solutions for the 5 Critical Health Dangers of Ammonia Leaks

Buyer’s Guide for Ammonia Gas Monitor

An Expert 7-Point Checklist for Industrial Gas Detection Systems

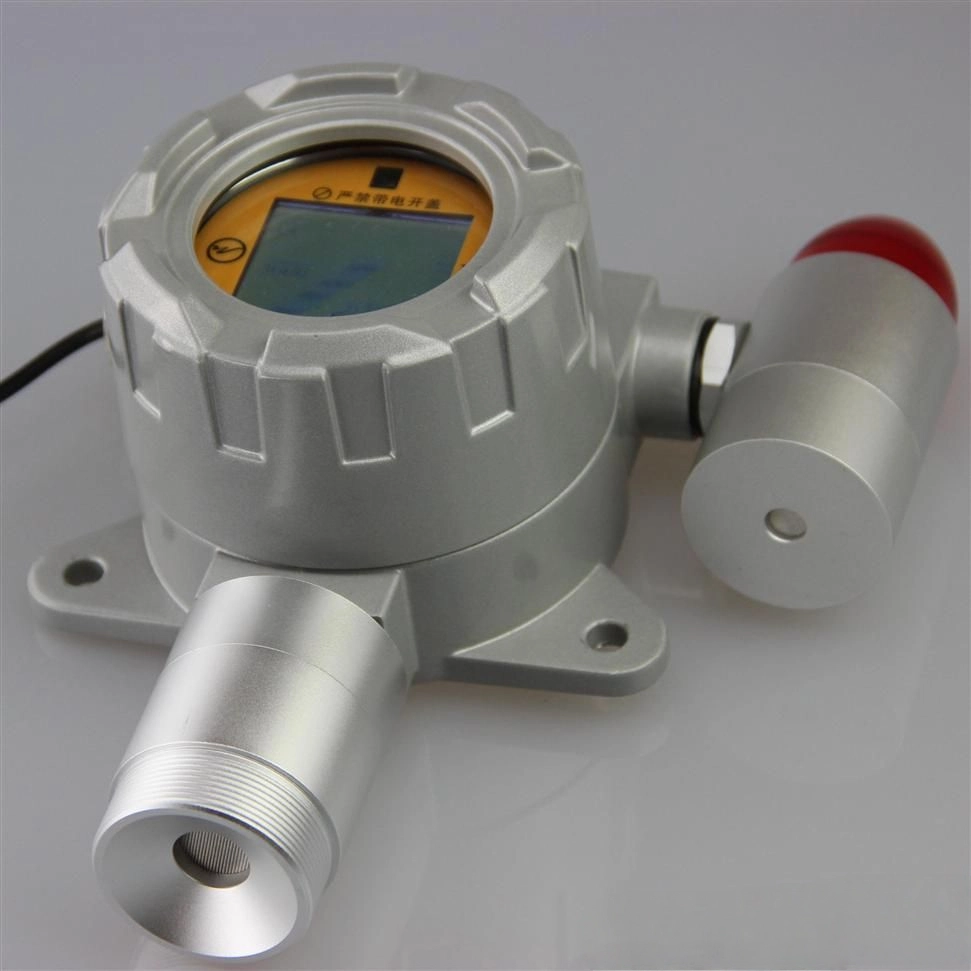

Sino-Inst’s Explosion-proof Gas Sampling System is an online monitoring system for waste gas at plant boundaries/stationary sources, independently developed and manufactured by our company. The sensors are imported high-precision electrochemical, PID photoionization, infrared, and catalytic combustion sensors. It employs a pump-suction sampling method for monitoring. An integrated water and dust removal filter effectively protects the sensors from damage. Customized audible and visual alarm devices are also available.

Request a Quote

.png)