The gas monitoring system is an intelligent system for real-time detection, analysis and recording of gas composition and concentration in the environment. Including various high-temperature gases, flammable gases, toxic gases, industrial waste gas, dust, temperature and humidity, etc.

It is widely used in industrial safety, environmental protection, petrochemical, energy production and other fields to ensure safe, compliant and efficient operation.

Sino-Inst’s portable gas detectors can monitor and control exhaust emissions, air pollution, and gas concentrations in industrial production, urban environments, and agricultural greenhouses. It can accurately capture small changes in gas concentrations in real time, thereby promptly detecting potential safety hazards.

Featured Products

Benefits

Real-time monitoring:

24/7 continuous monitoring of target gas concentration to ensure environmental safety.

Energy efficiency optimization:

Optimize combustion efficiency or production processes by monitoring industrial process gases.

Leakage warning:

Quickly locate leak points to reduce accident risks.

Emergency response:

Link with fire protection and ventilation systems to reduce accident hazards.

Compliance management:

Automatically generate emission reports to meet environmental regulations (such as EPA, EU ETS).

Support customization:

Dustproof and waterproof design (IP65/67), high temperature/corrosion resistant materials (such as titanium alloy housing), detection principle and other customizations.

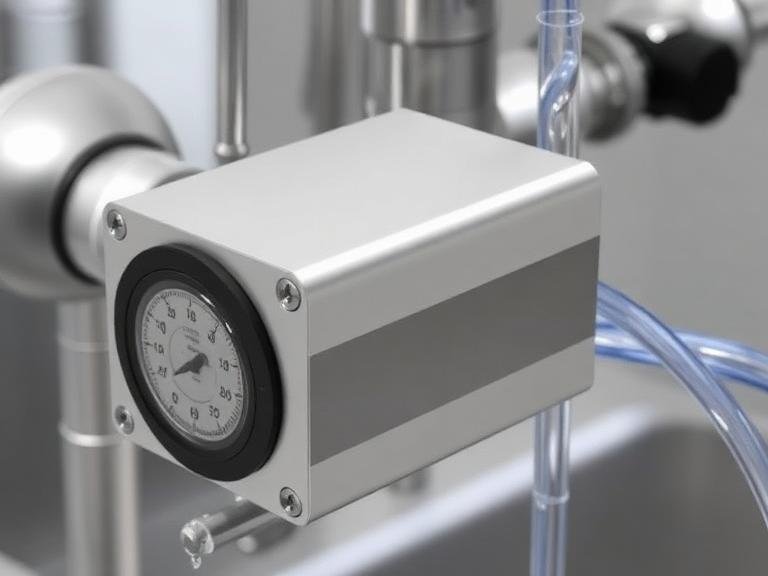

Components of the Gas Monitoring System

Commonly used gas monitoring systems basically have similar system structures. For example, VOCS exhaust gas monitoring system, methane/oxygen/hydrogen sulfide gas online monitoring system, nitrogen oxide online detection system, greenhouse gas online monitoring system, etc.

Gas Sensor

Detection gas objects:

Combustible gases (such as methane, hydrogen), toxic gases (such as carbon monoxide, hydrogen sulfide), oxygen concentration, volatile organic compounds (VOCs), greenhouse gases (such as CO₂), etc.

Sensor types:

Electrochemical sensors (detect toxic gases), infrared sensors (detect CO₂, CH₄), catalytic combustion sensors (detect combustible gases), photoionization detectors (PID, for VOCs), etc.

Central Control and Analysis System

Real-time monitoring: Display gas concentration dynamic curve, alarm status and equipment operation status.

Data analysis: Use algorithms to identify gas leakage trends, abnormal peaks or long-term pollution sources.

Automatic control: Trigger linkage devices (such as ventilation systems, emergency shut-off valves).

Data Acquisition and Transmission Module

Collect sensor data in real time and transmit it to the control center via wired (RS485, Ethernet) or wireless (Wi-Fi, 4G/5G, LoRa, NB-IoT) communication.

Support edge computing and perform preliminary data processing (such as filtering and calibration).

Alarm and Safety System

Multi-level alarm mechanism (threshold alarm, trend alarm), supports sound and light alarm, SMS/email notification.

Explosion-proof design (suitable for flammable and explosive environments, such as chemical plants, oil and gas well sites).

User interface and remote management

Local interface: Touch screen or industrial computer displays real-time data.

Cloud platform: supports remote access, historical data query, and generates compliance reports (such as EPA, OSHA standards).

Typical Applications

| Industry | Application scenarios |

| Industrial safety: | Monitoring flammable/toxic gases in chemical plants, oil and gas storage tank areas, and underground coal mines to prevent explosions or poisoning accidents. |

| Environmental monitoring: | Urban air quality monitoring stations and industrial park boundaries monitor VOCs, PM2.5, SO₂ and other pollutant emissions. |

| Energy industry: | Natural gas pipeline leakage monitoring, gas composition analysis of biogas power plants. |

| Laboratory and medical: | Laboratory harmful gas monitoring, hospital oxygen concentration monitoring. |

| Public places: | Underground parking lot CO monitoring, tunnel NO₂ concentration control. |

Technical Support

The gas monitoring system is used to realize real-time monitoring of gas concentration information, real-time alarm, historical alarm query, historical trend query, historical report, distribution map, SMS alarm and other functions. It is convenient for users to timely grasp the situation of flammable/toxic gases in the environment to prevent explosion and poisoning accidents.

Sino-Inst supplies reliable gas monitoring systems that can be customized according to specific needs. If you need to purchase a gas monitoring system, please contact our sales engineer!

Request a Quote

More Resources

-

The 10 Best Digital carbon monoxide detectors 2026: An Industrial Guide

Carbon monoxide (CO) remains one of the most hazardous invisible threats in industrial, commercial, and residential environments. Colorless, odorless, and tasteless, it requires…

-

Can gas detectors detect multiple gases simultaneously?

In the complex and often hazardous world of industrial manufacturing, petrochemical processing, and confined space operations, ensuring the safety of personnel is the…

-

Surface Water vs Groundwater: A Comprehensive Guide to Water Quality

In the domains of environmental engineering and industrial water management, knowing the basic differences between surface water vs groundwater is not just an academic…

-

What is the pH of Reverse Osmosis Water? The Complete Science Guide (2026)

If you have ever been curious about ‘what is the pH of reverse osmosis water?’, you are not alone. This is one of…

-

The Top 8 Portable CO Detector for Car Use

Introduction: The Silent Threat in Automotive Cabins Carbon monoxide (CO) is a colorless, odorless, and highly toxic gas generated by the incomplete combustion…

-

6 Best Mass Flow Controller for Liquids: An Expert Technology Guide

In modern industrial automation, pharmaceutical manufacturing, and semiconductor fabrication, the precise control of fluid dynamics is a fundamental requirement. Relying on outdated volumetric…

.png)