A photoionization detector (PID) is a highly sensitive analytical instrument designed for the broad-spectrum detection of volatile organic compounds (VOCs) and certain inorganic gases. Its operational principle is rooted in the ionization of gas molecules by high-energy ultraviolet (UV) light.

When a target gas molecule with an ionization potential (IP) lower than the energy of the detector’s UV lamp enters the sensor, it is ionized, creating a positively charged ion and a free electron. These charged particles generate a minute electrical current, which is proportional to the concentration of the gas. The detector amplifies this current and translates it into a real-time concentration reading, typically in parts per million (ppm) or parts per billion (ppb).

PIDs are favored in applications requiring rapid, non-destructive, and portable detection, such as industrial hygiene, hazardous material response, and environmental site assessments. Their effectiveness is contingent on the lamp’s energy output and the specific IP of the compounds being measured.

Featured PID Gas Detectors

The Fundamental Principle: Ionization by Light

To comprehend the function of a PID gas detector, we must first journey into the unseen world of molecules and energy. At its heart, the device performs a delicate dance of physics and chemistry, using light to make invisible chemical threats visible. The entire process hinges on a single, elegant concept: photoionization.

Imagine you need a specific key to open a specific lock. In the world of a PID, the “key” is a particle of ultraviolet light, and the “lock” is a molecule of a volatile organic compound. If the key has enough energy, the lock opens—the molecule is ionized—and the detector registers its presence. If the key is not energetic enough, the lock remains shut, and the molecule passes by undetected. This simple analogy forms the bedrock of our understanding.

What Are Volatile Organic Compounds (VOCs)?

Before we can appreciate how a detector a photoionization detector works, we must first understand what it is designed to find. Volatile Organic Compounds, or VOCs, are a vast family of carbon-based chemicals that share a particular characteristic: they have a high vapor pressure at ordinary room temperature . This high vapor pressure means they evaporate or “off-gas” easily, transitioning from a liquid or solid state into a gaseous one.

This family is incredibly diverse, encompassing chemicals like benzene, toluene, acetone, ethanol, and formaldehyde (Lai, 2024). They are ubiquitous in industrial processes, found in fuels, solvents, cleaners, paints, adhesives, and plastics.

While many VOCs are harmless, a significant number pose serious health risks to humans and can harm the environment. Some are carcinogens, others are neurotoxins, and many contribute to the formation of ground-level ozone and smog. It is this potential for harm that makes their detection so vital in occupational safety and environmental protection. The very property that defines them—their volatility—is what allows them to become airborne hazards that require sensitive monitoring.

The Role of Ultraviolet (UV) Light

The “photo” in photoionization refers to light. Specifically, a PID uses a lamp that emits high-energy ultraviolet (UV) light. UV light is a form of electromagnetic radiation, just like the visible light our eyes can see, but with a shorter wavelength and therefore higher energy. A PID does not simply shine a flashlight into a gas sample; it bombards the sample with photons, which are individual packets of light energy.

The amount of energy a photon carries is directly related to the wavelength of the light. The shorter the wavelength, the more energy each photon possesses. The UV lamps used in PIDs are engineered to produce photons with a very specific, known amount of energy, measured in a unit called an electron volt (eV). This precision is not arbitrary; it is the central mechanism of the detector’s operation. The energy of these photons is the “key” we mentioned earlier, and its value determines which “locks”—which chemical compounds—the detector can open.

Ionization Potential (IP): The Key to Detection

Every chemical compound has a property known as its ionization potential (IP), also measured in electron volts (eV). The IP is the minimum amount of energy required to dislodge an electron from a molecule of that compound, turning the neutral molecule into a positively charged ion. Each VOC has a unique IP value, a sort of chemical fingerprint. For example, the IP of benzene is 9.24 eV, while the IP of ammonia is 10.18 eV.

Here is the crucial connection: a PID can only detect a compound if the energy of its UV lamp is greater than the ionization potential of that compound.

If a molecule of benzene (IP = 9.24 eV) enters a PID with a standard 10.6 eV lamp, the photons from the lamp have more than enough energy to knock an electron off the benzene molecule. The benzene molecule is ionized. However, if a molecule of methane (IP = 12.61 eV) enters the same detector, the 10.6 eV photons are not energetic enough. They strike the methane molecule but lack the force to dislodge an electron. The methane molecule remains neutral and passes through the detector unnoticed.

This is the fundamental principle of what a photoionization detector does: it uses a specific energy of light to selectively ionize compounds based on their unique ionization potentials.

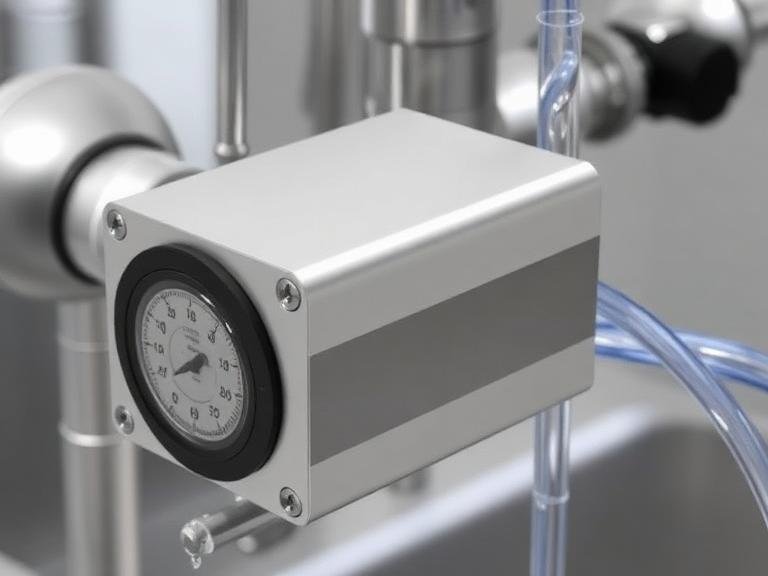

Anatomy of a PID: A Look Inside the Sensor

Having grasped the theoretical underpinnings, we can now disassemble the device to inspect its core components. A PID is an elegant assembly of a few critical parts working in concert. It is not a black box, but a thoughtfully designed instrument where each piece plays a distinct and indispensable role in the journey from an invisible gas to a quantifiable reading on a screen. Understanding this internal architecture illuminates how the abstract principle of photoionization is translated into a practical, life-saving tool.

The UV Lamp: The Heart of the Detector

The UV lamp is, without question, the most important component of a PID. It is the source of the high-energy photons that drive the entire detection process. These lamps are not like household light bulbs; they are specialized gas-discharge lamps filled with a noble gas, such as krypton, argon, or xenon. An electrical current is passed through the gas, causing it to emit light at a very specific wavelength and, therefore, a specific energy.

The choice of gas determines the lamp’s output energy. The most common lamps in PIDs are:

- 10.6 eV Lamp: Filled with krypton, this is the workhorse of the PID world. It can detect a very broad range of VOCs and is relatively long-lasting and robust.

- 9.8 eV Lamp: Also filled with krypton but with a different window material, this lamp offers greater selectivity. It will not ionize some compounds that the 10.6 eV lamp can, which can be useful for eliminating certain interferences.

- 11.7 eV Lamp: Filled with argon, this is the most powerful standard lamp. It can detect a wider range of compounds than the 10.6 eV lamp, including some chlorinated solvents like chloroform and some inorganic gases like ammonia. However, it has a much shorter operational life and is more fragile.

The lamp’s performance is paramount. Over time, the window of the lamp can become dirty from exposure to contaminants, which blocks the UV light and reduces the detector’s sensitivity. This is why regular cleaning is a non-negotiable aspect of PID maintenance.

| Lamp Energy | Gas Fill | Common Detectable Compounds | Common Undetectable Compounds | Typical Lifespan |

| 9.8 eV | Krypton | Aromatic hydrocarbons (Benzene, Toluene), some large molecules | Ammonia, Acetone, Methanol, Ethanol | Long |

| 10.6 eV | Krypton | Most VOCs, including those above, plus Acetone, Ethanol, Diesel | Methane, Carbon Monoxide, Formaldehyde, Natural Gas | Long |

| 11.7 eV | Argon | Most VOCs, plus Formaldehyde, Ammonia, Chloroform | Methane, Carbon Monoxide, Oxygen, Nitrogen | Short |

The Ionization Chamber and Electrodes

Directly adjacent to the UV lamp is the ionization chamber. This is the small, defined space where the magic happens. A pump, either internal or external to the instrument, draws a continuous sample of the ambient air into this chamber. As the air sample flows past the lamp’s window, it is bathed in UV light.

Inside this chamber are two electrodes: a positive electrode and a negative electrode. A small voltage is applied across them, creating an electrical field. In the absence of any ionizable gas, the air in the chamber (composed mostly of nitrogen, oxygen, and argon) is a poor conductor of electricity, so no current flows between the electrodes. The molecules of normal air components have very high ionization potentials (e.g., Nitrogen IP = 15.6 eV) and are unaffected by the UV lamp.

When a VOC with a suitable IP enters the chamber and is ionized by the UV light, the molecule is split into two charged particles: a negatively charged electron and a much larger, positively charged molecular remnant. The electric field immediately goes to work, pulling the negatively charged electrons toward the positive electrode and the positive ions toward the negative electrode.

The Amplifier and Signal Processing

The movement of these countless electrons and ions toward the electrodes constitutes a tiny electrical current. We are talking about a current measured in picoamperes (trillionths of an ampere)—an incredibly small signal. This faint signal is far too weak to be measured directly.

This is where the amplifier comes in. It is an electronic circuit that takes the minuscule current from the electrodes and magnifies it by a factor of millions or even billions, producing a robust and measurable electrical signal. The strength of this amplified signal is directly proportional to the number of molecules that were ionized in the chamber. More molecules mean more ions and electrons, which means a larger initial current, resulting in a stronger amplified signal.

The final step is for the instrument’s microprocessor to take this amplified signal and, using a calibration algorithm, convert it into a concentration reading. This reading is then displayed on the screen, typically in units of parts per million (ppm) or parts per billion (ppb), providing the user with a real-time measurement of the VOC concentration in the air.

Measurement Process: From Gas to Reading

We have explored the theory and the hardware. Now, let us synthesize this knowledge and trace the complete path of a single measurement, from the moment a gas molecule enters the instrument to the moment a number appears on its display. This step-by-step examination clarifies how a photoionization detector works in a dynamic, continuous process, transforming a chemical property into actionable data. It is a rapid sequence of events, a miniature analytical chain reaction that repeats itself many times per second.

Gas Sample Introduction

The process begins with the instrument’s sampling system. Most PIDs, whether handheld or fixed, are active monitors, meaning they use a small diaphragm pump to actively draw air into the sensor. This ensures a constant and controlled flow of the sample into the ionization chamber. The inlet of the instrument is often equipped with a filter to prevent dust, particulates, and water droplets from entering and contaminating the sensitive internal components, particularly the UV lamp and electrodes. For a safety professional investigating a potential leak, this means simply pointing the probe of the instrument toward the suspected source and allowing the pump to deliver the sample for analysis.

The Ionization Event and Current Generation

As the stream of sampled air enters the ionization chamber, it flows directly across the quartz or magnesium fluoride window of the UV lamp. Here, the air is flooded with high-energy photons. For a brief moment, every molecule in the sample is exposed to this energy.

Let’s imagine our sample contains clean air mixed with a small amount of toluene vapor (IP = 8.82 eV). The PID is equipped with a standard 10.6 eV lamp.

- The photons strike the nitrogen and oxygen molecules. Since their IPs are much higher than 10.6 eV, nothing happens. They remain electrically neutral.

- The photons strike the toluene molecules. Because 10.6 eV is greater than 8.82 eV, the energy is sufficient. An electron is ejected from each toluene molecule it strikes with enough energy.

- The result is a cloud of positively charged toluene ions (C7H8+) and free electrons (e-).

The voltage applied to the electrodes within the chamber immediately acts upon this cloud of charged particles. The positive toluene ions are attracted to the negative electrode (the cathode), while the free electrons are drawn to the positive electrode (the anode). This directed movement of charge is, by definition, an electrical current. The magnitude of this current is directly proportional to the number of toluene molecules that were ionized, which in turn is directly proportional to the concentration of toluene in the original air sample.

Translating Current into Concentration (ppm/ppb)

The raw signal generated at the electrodes is an analog electrical current. The instrument’s internal electronics must convert this into a digital value that represents a concentration. The amplified current is fed into an analog-to-digital converter (ADC), which transforms the signal into a numerical count.

This count, however, is not yet a concentration reading. To make that final leap, the PID relies on its calibration. During calibration, the instrument is exposed to a known concentration of a specific gas, typically isobutylene. The user tells the instrument, “The gas you are currently reading is 100 ppm of isobutylene.” The PID measures the electrical current produced by that 100 ppm concentration and stores that value. It now has a reference point. For example, it learns that a signal of ‘X’ microamps corresponds to 100 ppm of isobutylene.

When it later measures an unknown sample and generates a signal of ‘0.5X’ microamps, its internal algorithm performs a simple ratio calculation and displays a reading of “50 ppm.” This is why calibration is not just a recommendation; it is a fundamental requirement for any quantitative use of a PID. Without it, the instrument can only tell you if something is present, not how much. Read more about: Foundational Principles of Gas Detection and Calibration

The Role of Correction Factors

A PID is a broad-spectrum detector. When calibrated to isobutylene, its readings are only truly accurate for isobutylene. Different compounds ionize with different efficiencies. Some molecules give up their electrons more readily than others, even if their IPs are similar. This means that 100 ppm of benzene will produce a different electrical current than 100 ppm of toluene, which will be different again from 100 ppm of isobutylene.

To account for this, manufacturers publish lists of “Correction Factors” (CFs). A correction factor is a multiplier used to convert the PID’s reading (which is relative to the calibration gas) to the actual concentration of a specific target gas.

The formula is: Actual Concentration = PID Reading × Correction Factor

For example, benzene has a CF of approximately 0.5 when the PID is calibrated with isobutylene. If you know you are measuring only benzene and your PID reads “10 ppm,” the actual concentration of benzene is 10 ppm × 0.5 = 5 ppm. Conversely, acetone has a CF of approximately 1.1. A reading of “10 ppm” in an environment with only acetone would mean the actual concentration is 10 ppm × 1.1 = 11 ppm.

Most modern PIDs have libraries of these CFs built into their software. The user can select the target compound, and the instrument will automatically apply the correction factor and display the corrected, true concentration. It is vital to remember, however, that this only works if you are measuring a single, known gas. In a mixture of unknown VOCs, the reading is best interpreted as a “total VOC” concentration relative to the calibration gas.

What PIDs Can and Cannot Do

A deep understanding of any instrument requires an honest appraisal of not only its strengths but also its weaknesses. A photoionization detector is an exceptionally powerful tool, but it is not a silver bullet for all gas detection challenges. Its utility is defined as much by what it cannot do as by what it can. Acknowledging these limitations is the mark of a skilled and responsible user, preventing misinterpretation of data and ensuring the right tool is chosen for the right job. The effectiveness of a PID gas detector is a function of its inherent design, and we must work within those constraints.

Broad-Spectrum vs. Selective Detection

The primary characteristic of a PID is that it is a broad-spectrum, non-selective detector.

- Broad-Spectrum: It can detect hundreds, even thousands, of different chemical compounds, provided their IP is below the lamp energy. This is a major advantage in emergency response or site assessment scenarios where the exact nature of the chemical hazard may be unknown. A PID can quickly confirm the presence of “something” hazardous.

- Non-Selective: This is the flip side of the same coin. A PID cannot, by itself, distinguish between different compounds. If benzene (IP 9.24 eV) and toluene (IP 8.82 eV) are both present, a 10.6 eV PID will ionize both. The resulting reading is a single number representing the total response from all detectable compounds in the sample. It cannot tell you that you have 3 ppm of benzene and 5 ppm of toluene. It will simply give a combined reading relative to its calibration gas.

This is a critical point. A PID is excellent for screening and quantifying a known, single gas. It is not an analytical instrument for identifying the components of a complex mixture. For that, one would need a more sophisticated technique like gas chromatography (GC), which often uses a PID as its final detector (a GC-PID).

| Sensor Type | Principle of Operation | Selectivity | Common Targets | Typical Use Case |

| Photoionization (PID) | UV light ionizes gas molecules. | Broad-spectrum, non-selective for detectable VOCs. | Hundreds of VOCs (Benzene, Toluene). | HazMat, industrial hygiene, environmental screening. |

| Catalytic Bead (LEL) | Gas oxidizes on a heated catalyst, changing resistance. | Broad-spectrum for flammable gases. | Methane, Propane, Hydrogen. | Confined space entry, flammable gas monitoring. |

| Electrochemical (EC) | Gas reacts at an electrode, producing a current. | Highly selective for a specific gas. | Carbon Monoxide, H₂S, Chlorine, Oxygen. | Toxic gas safety, life safety alarms. |

| Infrared (IR) | Gas absorbs infrared light at specific wavelengths. | Can be selective or broad-spectrum. | Carbon Dioxide, Hydrocarbons (Methane). | CO₂ monitoring, flammable gas detection in low O₂. |

The Impact of Lamp Energy (eV)

As we have discussed, the lamp energy is the gatekeeper of detection. The choice of lamp is the primary way to introduce a degree of selectivity into a PID measurement. For instance, if you are concerned about benzene (IP 9.24 eV) in a workplace where large amounts of ethanol (IP 10.47 eV) are also present, a standard 10.6 eV lamp would be problematic. It would detect both, and the high concentration of ethanol could mask the low, hazardous levels of benzene.

In this scenario, switching to a 9.8 eV lamp would be a strategic choice. The 9.8 eV lamp has enough energy to ionize the benzene, but not enough to ionize the ethanol. The PID would effectively become “blind” to the ethanol, allowing it to provide a much more accurate reading of the benzene concentration. This ability to tune the detection window by swapping lamps is a powerful feature for knowledgeable users. However, one must always be aware of what other compounds might be present that could still interfere.

Common Interferences: Humidity and Methane

Beyond the fundamental limitation of non-selectivity, PIDs are susceptible to certain environmental and chemical interferences.

- Humidity: High humidity is a well-known challenge for PIDs. Water molecules can absorb some of the UV energy, causing a slight negative drift in the reading (a phenomenon known as “quenching”). In very high humidity, water can also condense on the lamp and electrodes, which can scatter the UV light or even cause a short circuit, leading to inaccurate or fluctuating readings. Modern PIDs often incorporate humidity sensors and software algorithms to compensate for these effects, and some designs, like those with “Fence Electrode Technology,” are specifically engineered for increased resistance to moisture.

- Methane: Methane is the primary component of natural gas. Its ionization potential is 12.61 eV. This is higher than the energy of even the most powerful standard PID lamp (11.7 eV). Consequently, a PID cannot detect methane. This is both a limitation and, at times, an advantage. For environmental remediation work at a landfill, where high concentrations of both methane and toxic VOCs are present, a PID is an excellent tool. It can measure the hazardous VOCs while completely ignoring the background methane, which would overwhelm other sensor types like catalytic bead sensors.

- Particulates and Aerosols: Dust, smoke, and oil mists can coat the inside of the sensor, particularly the lamp window. This film blocks the UV light from reaching the gas sample, drastically reducing the instrument’s sensitivity. This is why proper filtering and regular cleaning are so important, especially in dirty industrial environments.

When to Choose a PID over Other Sensor Types

The decision to use a PID should be based on the specific application and the chemical hazards involved. A PID is the superior choice when:

- The target hazard is a VOC with an IP below 11.7 eV.

- Very low detection limits are required (ppm or ppb levels).

- A rapid, real-time response is needed.

- The identity of the VOC is unknown, and a broad-spectrum screening tool is necessary.

- You need to measure low-level toxic VOCs in the presence of high concentrations of methane or other non-detectable gases.

A PID is generally not the right choice for:

- Life-safety monitoring for flammable gases in a confined space (a catalytic LEL sensor is standard).

- Detecting specific toxic gases like carbon monoxide or hydrogen sulfide when other VOCs are not a concern (an electrochemical sensor is more selective and cost-effective).

- Measuring gases with very high IPs, such as methane, carbon dioxide, or Freons.

- Identifying the specific components of a gas mixture.

Applications and Maintenance

Theory and mechanics are foundational, but the true measure of an instrument is its utility in the field. From the fenceline of a refinery to the site of a chemical spill, PIDs provide the immediate data that informs critical decisions. Yet, like any precision instrument, their reliability is directly tied to the care and diligence of the operator. Proper application and routine maintenance are the two pillars that support accurate and trustworthy measurements.

Industrial Hygiene and Worker Safety

Perhaps the most common application for PIDs is in industrial hygiene. An industrial hygienist is tasked with anticipating, recognizing, evaluating, and controlling workplace conditions that may cause workers’ injury or illness. Many industrial processes involve the use of solvents, fuels, and chemical feedstocks that are toxic VOCs.

For example, workers in paint mixing plants are frequently exposed to mixtures of various solvents such as toluene, xylene, and methyl ethyl ketone (MEK). Handheld PID (Potentially Detecting and Discharging) devices can be used to measure the concentration of these solvents in the worker’s breathing zone. If the reading is close to or exceeds the established occupational exposure limit (OEL), it indicates a need to improve ventilation, replace personal protective equipment (PPE) with better equipment, or improve work processes.

PID devices can also be used for leak detection, quickly locating faulty valves or leaking containers to prevent the release of harmful vapors into the workplace.

Environmental Monitoring and HazMat Response

In the environmental sector, PIDs are indispensable. When investigating a contaminated land site, such as a former gas station or industrial facility, a PID is the primary screening tool. Consultants will use it to perform soil headspace analysis, where a soil sample is placed in a sealed bag, allowed to warm, and the PID’s probe is inserted to measure the off-gassing VOCs. This allows them to quickly map the extent of contamination without the delay and expense of sending hundreds of samples to a lab.

For hazardous materials (HazMat) response teams, a PID is a frontline instrument. When arriving at a tanker truck rollover or a chemical fire, the first question is “What are we dealing with, and how far has it spread?” A PID allows first responders to quickly assess the presence of unknown vapors from a safe distance (Epping & Koch, 2023). By walking the perimeter of the incident and monitoring the readings, they can establish hot, warm, and cold zones, ensuring that emergency personnel and the public are not exposed to a toxic plume. While the PID cannot identify the chemical, its reading provides immediate, actionable information about the presence and relative concentration of a potential threat.

Routine Care: Cleaning and Calibration

A PID is only as good as its last calibration. The performance of the instrument will drift over time due to lamp aging, sensor contamination, and electronic component changes. To ensure accuracy, two routine procedures are required:

- Cleaning: The UV lamp is the most critical component to keep clean. Any film of dirt or oil on the lamp window will block UV light and reduce the instrument’s sensitivity. The lamp and sensor should be inspected and cleaned regularly, following the manufacturer’s specific instructions. This typically involves wiping the lamp window with a recommended solvent like methanol on a cotton swab.

- Calibration: This is the process of adjusting the instrument’s response to match a known concentration of gas. It involves two main steps:

- Zeroing: The instrument is exposed to clean, uncontaminated air (or a cylinder of zero-grade air) to set its zero point.

- Spanning: The instrument is exposed to a known concentration of a calibration gas (usually isobutylene) from a certified cylinder. The user then adjusts the instrument’s reading to match the concentration value printed on the cylinder.

How often should this be done? A “bump test,” a brief exposure to calibration gas to verify sensor response, should be performed before each day’s use. A full calibration should be performed according to manufacturer recommendations and company policy, typically on a monthly or quarterly basis, or anytime the instrument has been subjected to physical shock or high concentrations of contaminants.

Ensuring Accuracy with a Fixed VOC Monitor

For applications requiring 24/7 protection, handheld PIDs are insufficient. In these cases, a Fixed VOC Monitor provides a permanent solution. These units are installed in a specific location, such as near a chemical storage tank, along a production line, or at the fenceline of a facility. They operate continuously, sampling the air and providing real-time data to a central control system.

These continuous VOC detection systems can be configured to trigger alarms—both audible and visual—if the VOC concentration exceeds a pre-set level. This provides an immediate warning of a leak or hazardous condition, allowing for automated shutdowns or the prompt evacuation of personnel, even when no one is physically present to take a measurement. They are a cornerstone of modern industrial safety systems, offering a level of vigilance that periodic spot-checking with a handheld unit cannot match.

FAQ

Related Products

The photoionization detector stands as a testament to the elegant application of fundamental physics to solve a pressing real-world problem. By harnessing the energy of ultraviolet light to ionize volatile organic compounds, it grants us a sense of sight into the invisible chemical world.

A nuanced understanding reveals that the PID is not an infallible oracle, but a sophisticated instrument with distinct capabilities and limitations. Its power lies in its broad-spectrum sensitivity, providing rapid, real-time data in the parts-per-million and parts-per-billion range. Its limitation lies in its non-selectivity, a characteristic that demands intelligent interpretation from the user.

For the industrial hygienist protecting worker health, the HazMat responder securing a dangerous scene, or the environmental scientist assessing a contaminated site, knowing how a photoionization detector works is the first step toward using it effectively and responsibly.

More Resources

-

The 10 Best Digital carbon monoxide detectors 2026: An Industrial Guide

Carbon monoxide (CO) remains one of the most hazardous invisible threats in industrial, commercial, and residential environments. Colorless, odorless, and tasteless, it requires…

-

Can gas detectors detect multiple gases simultaneously?

In the complex and often hazardous world of industrial manufacturing, petrochemical processing, and confined space operations, ensuring the safety of personnel is the…

-

Surface Water vs Groundwater: A Comprehensive Guide to Water Quality

In the domains of environmental engineering and industrial water management, knowing the basic differences between surface water vs groundwater is not just an academic…

-

What is the pH of Reverse Osmosis Water? The Complete Science Guide (2026)

If you have ever been curious about ‘what is the pH of reverse osmosis water?’, you are not alone. This is one of…

-

The Top 8 Portable CO Detector for Car Use

Introduction: The Silent Threat in Automotive Cabins Carbon monoxide (CO) is a colorless, odorless, and highly toxic gas generated by the incomplete combustion…

-

6 Best Mass Flow Controller for Liquids: An Expert Technology Guide

In modern industrial automation, pharmaceutical manufacturing, and semiconductor fabrication, the precise control of fluid dynamics is a fundamental requirement. Relying on outdated volumetric…

.png)