In the rapidly evolving industrial landscape of 2026, personnel safety and asset protection have reached new heights of technological integration. Choosing the Best fixed gas detection system is no longer just a regulatory checkbox; it is a critical component of a smart facility’s infrastructure. From chemical processing plants to wastewater treatment facilities, the ability to monitor toxic and combustible gases in real-time is paramount for preventing catastrophic incidents.

Modern systems in 2026 prioritize wireless connectivity, cloud-based data logging, and modular sensor designs. This article provides a deep dive into the top-rated solutions currently leading the market, focusing on accuracy, response time, and ease of integration. Whether you are upgrading an existing facility or designing a new one, understanding the technical nuances of the Best fixed gas detection system will ensure long-term reliability and safety.

- 2026 Industrial Gas Detection Market Trends

- 1. Sino-Inst Wall-mounted Temperature and Humidity Monitor

- 2. Sino-Inst Fixed Gas Detector with Remote Sensor

- 3. Honeywell Manning AirAlert Series

- 4. MSA Ultima X5000 Gas Monitor

- 5. Dräger Polytron 8000 Series

- 6. Industrial Scientific Radius BZ1 Area Monitor

- Technical Comparison and Specifications

- Frequently Asked Questions

- References and Safety Standards

2026 Industrial Gas Detection Market Trends

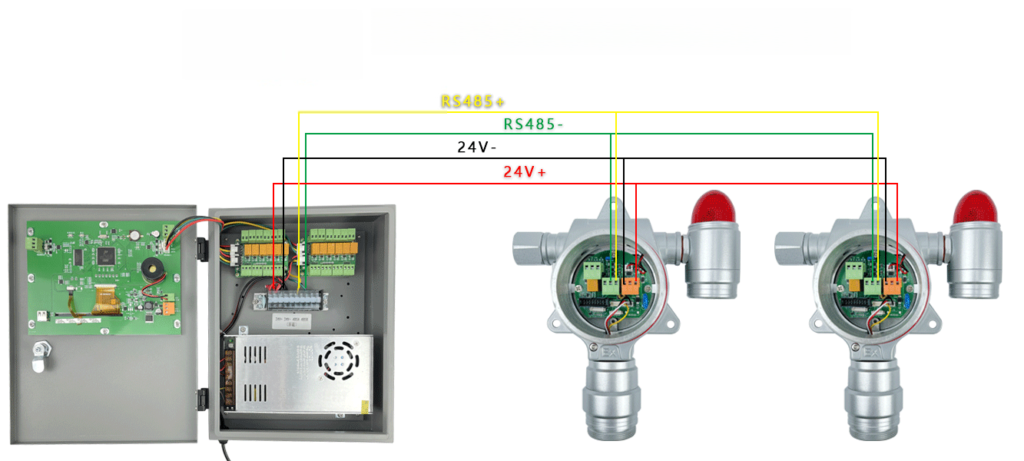

The Best fixed gas detection system configurations in 2026 are increasingly defined by their communication protocols. While traditional 4-20mA analog signals remain a baseline, there is a massive shift toward RS485 Modbus and wireless mesh networks. These digital interfaces allow for remote diagnostics, meaning technicians can calibrate and troubleshoot sensors without ever entering a hazardous zone.

Environmental monitoring has also converged with gas detection. Modern facilities now require integrated solutions that monitor not just gas concentrations, but also ambient conditions like temperature and humidity, which can affect sensor accuracy and the behavior of heavier-than-air gases. The Best fixed gas detection system of 2026 is an ecosystem, rather than a standalone device.

1. Sino-Inst Wall-mounted Temperature and Humidity Monitor for Ambient

While primary gas detection is critical, monitoring the environment in which sensors operate is the first step in ensuring system longevity. The Sino-Inst Wall-mounted Monitor is a foundational piece of the Best fixed gas detection system infrastructure, particularly for sensitive indoor storage areas or outdoor process zones.

Key Features

- Sturdy, flameproof housing suitable for diverse indoor and outdoor environments.

- Large LCD screen intuitively displays real-time parameters.

- Temperature compensation and linearization circuitry ensure stability and accurate measurements.

- Fault detection added to the RS485 communication protocol for enhanced reliability.

- Remote control maintenance allows for on-site adjustment without opening the housing.

Technical Specifications

| Detection Type | Process Temperature and Humidity HUMI-T/C |

|---|---|

| Detection Range | Temp: -40~125°C; Humidity 0~100% RH |

| Accuracy | ≤±3% |

| Signal Output | 4-20mA, RS485 (Modbus RTU), Voltage (0-5V/0-10V) |

| Alarm Method | Onsite audible/visual, external, and remote alarms |

2. Sino-Inst Fixed Gas Detector with Remote Sensor

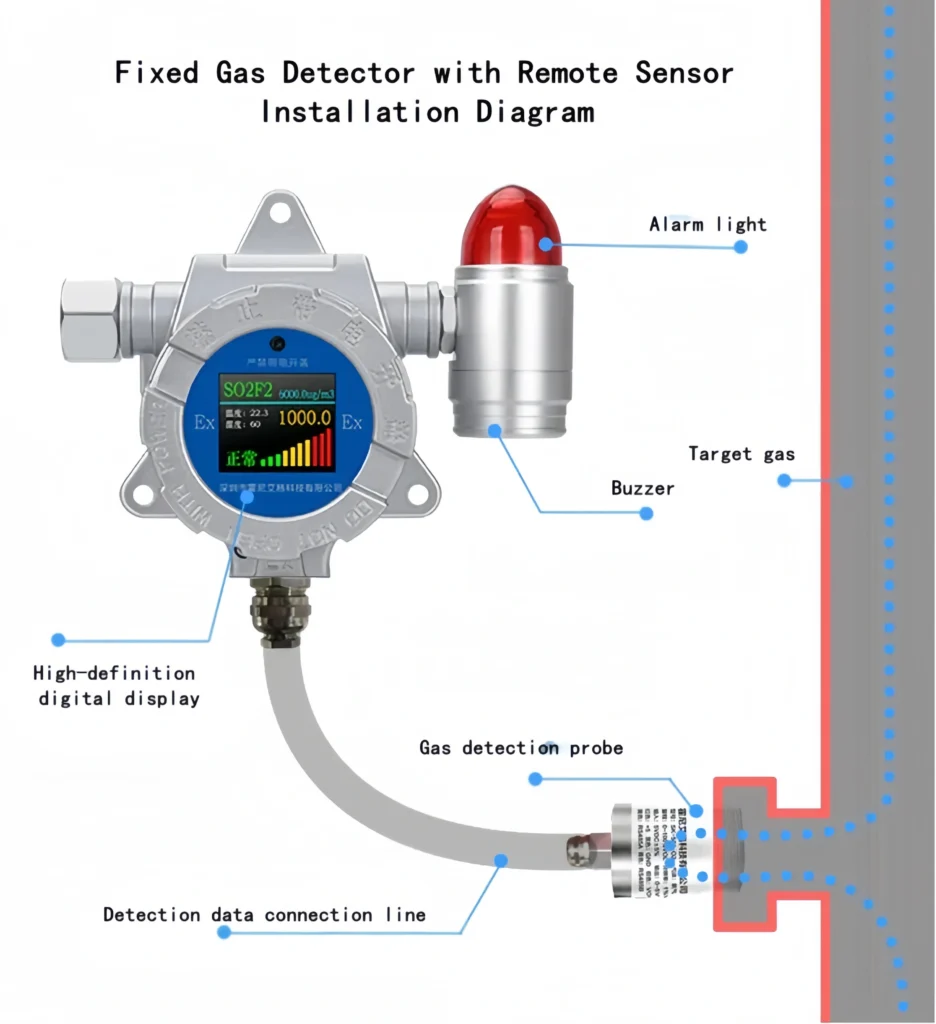

The Sino-Inst Fixed Gas Detector stands out as a top-tier candidate for the Best fixed gas detection system due to its modular remote sensor capability. This allows the sensitive electrochemical sensors to be placed in hard-to-reach or high-risk areas while the main display and controls remain in a safe, accessible location.

Technical Specifications

| Measuring Range | 0-1000/10000PPM; 0-100%VOL; 0-100%LEL |

|---|---|

| Principle | Electrochemical (Toxic gases), Catalytic/Infrared (Combustibles) |

| T90 Response Time | Less than 30 seconds |

| Explosion Proof | Ex d IIC T6 Gb |

| Protection Grade | IP66 (Dust and heavy water jet protection) |

This detector is highly customizable, with working temperatures ranging from -40°C to as high as 420°C for specialized zirconia oxygen sensors. It represents the pinnacle of versatility in a Best fixed gas detection system, offering high-precision standard 16-bit 4-20mA output for long-distance transmission up to 1km.

3. Honeywell Manning AirAlert Series

Honeywell has long been a leader in the industrial safety space, and their Manning AirAlert series is a mainstay for the Best fixed gas detection system in refrigeration and cold storage. In 2026, these units feature enhanced sensor life and “plug-and-play” replacement modules. The system is particularly efficient at detecting ammonia (NH3) and various refrigerants, utilizing electrochemical sensors that are specifically tuned to minimize cross-sensitivity with other common industrial chemicals.

4. MSA Ultima X5000 Gas Monitor

The MSA Ultima X5000 is widely considered the Best fixed gas detection system for heavy-duty oil and gas applications. Its dual-sensor capability allows one transmitter to monitor two different gases simultaneously, reducing installation costs and footprint. The X5000 features a unique touch-screen interface that can be operated through the explosion-proof glass, even with gloves on, which is a major benefit for field operators in 2026.

5. Dräger Polytron 8000 Series

Dräger’s Polytron 8000 is the Best fixed gas detection system for laboratories and pharmaceutical manufacturing. It supports over 100 different gas types through their proprietary “DrägerSensors.” The 2026 update includes an integrated web server, allowing safety managers to log in and check the status of every sensor across the facility from a central dashboard. Its logging functionality is essential for facilities that must comply with strict environmental reporting standards.

6. Industrial Scientific Radius BZ1 Area Monitor

While often classified as an “area monitor,” the Radius BZ1 is frequently used as a Best fixed gas detection system for temporary worksites or fence-line monitoring. Its LENS Wireless technology allows units to communicate with each other instantly, creating a safety web. If one unit detects gas, every unit in the network alarms. This peer-to-peer communication makes it a rugged, rapidly deployable alternative to traditional wired fixed systems.

Technical Comparison and Specifications

When evaluating the Best fixed gas detection system, technical parity is essential. Below is a comparison of key metrics that define operational efficiency in 2026.

| System Name | Primary Communication | Max Temp Range | Sensor Life (Est) | Best For |

|---|---|---|---|---|

| Sino-Inst Fixed Remote | RS485 / 4-20mA | -40 to 420°C | 2-3 Years | High-Temp & Remote Sensing |

| MSA Ultima X5000 | Bluetooth / HART | -40 to 60°C | 3-5 Years | Oil & Gas Platforms |

| Dräger Polytron 8000 | Ethernet / Modbus | -40 to 65°C | 2-4 Years | Lab & Pharma Toxicity |

| Radius BZ1 | Wireless Mesh | -20 to 55°C | 2 Years | Area & Perimeter Safety |

Pro Tip: For 2026, ensure your Best fixed gas detection system is compatible with your facility’s PLC or DCS. High-precision 16-bit 4-20mA outputs or Modbus RTU protocols are the industry standard for reliable long-distance data acquisition.

Frequently Asked Questions

How often should a fixed gas detection system be calibrated?

In 2026, most manufacturers recommend calibration every 4 to 8 months depending on the sensor type. Electrochemical sensors typically require more frequent zeroing (every 3-6 months) to account for baseline drift, while infrared sensors may remain stable for up to a year.

What is the difference between diffusion and pump-style detection?

Most entries for the Best fixed gas detection system use the diffusion method, where the gas naturally reaches the sensor. Pump-style systems (aspirated) are used when the sample must be pulled from a remote location, such as a deep tank or a pressurized duct.

Can these systems withstand outdoor weather?

Yes. Systems like those from Sino-Inst feature IP66 or IP67 ratings, meaning they are dust-tight and protected against powerful water jets. Flameproof and explosion-proof (Ex d IIC T6) housings are standard for Best fixed gas detection system candidates in 2026.

References and Safety Standards

- ISA 92.00.01: Performance Requirements for Toxic Gas Detectors.

- OSHA 1910.146: Permit-Required Confined Spaces and Atmospheric Monitoring.

Safe operations in 2026 depend on the precision and connectivity of your infrastructure. By choosing a Best fixed gas detection system that combines rugged hardware with intelligent communication protocols, you protect your most valuable assets.

.png)