Whether you are managing an industrial wastewater plant, running a high-tech shrimp farm, or maintaining a commercial swimming pool, your success depends on one thing: Water Quality.

If you get these numbers right, you have a safe, profitable operation. If you get them wrong, you face fines, dead stock, or safety hazards.

But with dozens of different parameters to track—from COD to pH to Conductivity—it is easy to get overwhelmed. Which ones actually matter? Which ones should you automate?

This guide moves beyond the dictionary definitions to give you a practical operating framework used by water treatment experts worldwide.

What Are water quality parameters?

Before we dive into strategy,let’s define the basics.

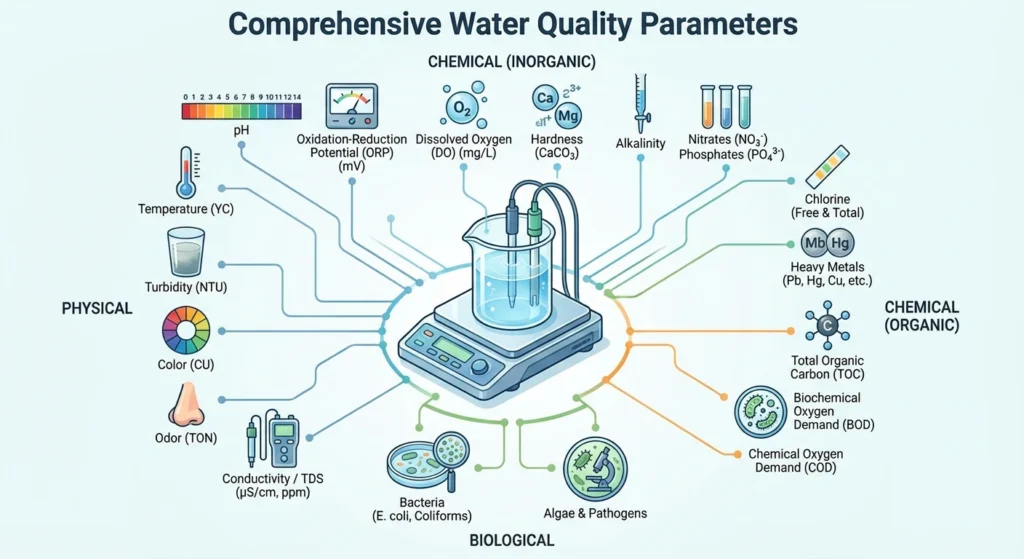

Water quality parameters are the physical,chemical,and biological characteristics used to measure the health and safety of water.They act as the “vital signs” of your water system.

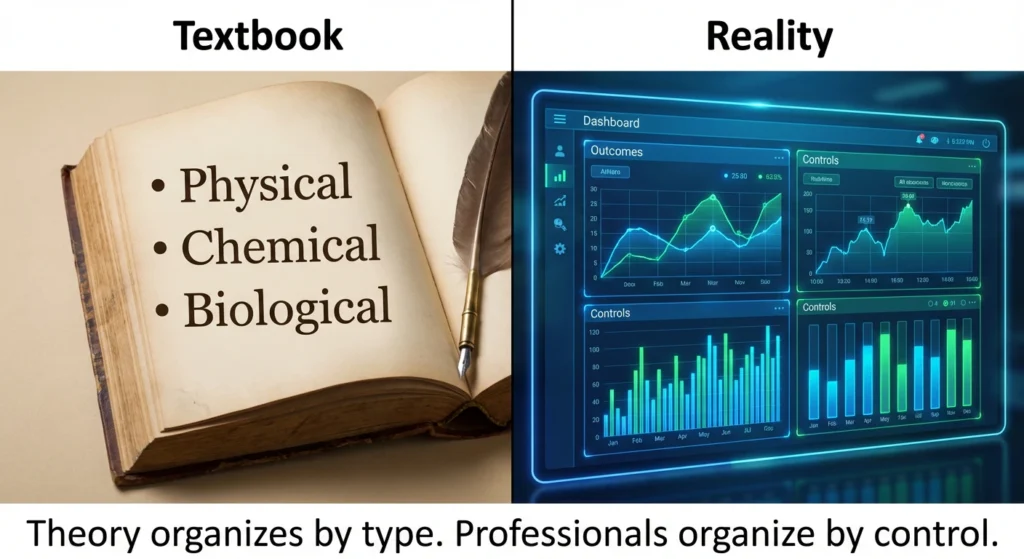

Traditionally,science textbooks categorize them into three standard groups:

- Physical: Temperature, Turbidity, Conductivity (EC), Color.

- Chemical: pH, Dissolved Oxygen (DO), Chemical Oxygen Demand (COD), Ammonia, Chlorine.

- Biological: Bacteria (E. coli), Algae, Plankton.

While this classification is scientifically correct, it is not very useful for daily operations.

Knowing that “Ammonia” is a chemical parameter doesn’t help you when your fish are dying or your discharge permit is denied. As a professional, you need a new way to categorize these metrics—one based on Action and Control.

Water Quality Parameters: Decision Table for Monitoring and Control

Key point: Automatic control isn’t needed for all aspects of water quality.

Some parameters are best for monitoring, and others are widely used for closed-loop control in dosing or process automation.

Should You Monitor or Control These Water Quality Parameters?

| Parameter | Typical Role | Control Needed? | Why It Matters | Common Control Action |

|---|---|---|---|---|

| pH | Process variable | ✅ Yes (Often) | Directly affects chemical reactions, corrosion, neutralization, and discharge compliance | Acid/alkali dosing via controller + pump |

| ORP (Redox) | Disinfection/oxidation indicator | ✅ Yes (Often) | Indicates oxidation strength, disinfectant efficiency, cyanide destruction, chlorine demand | Chlorine/NaOCl dosing; oxidant control |

| Turbidity | Water clarity/solids | ❌ Usually No | Mainly used for filtration performance and early warning | Filter backwash trigger / alarm |

| Conductivity | Ionic strength/salinity | ⚠ Sometimes | Used to control chemical concentration or monitor leakage / CIP | Blowdown control; dilution control |

| TDS | Dissolved solids | ❌ Usually No | Often derived from conductivity; mostly monitoring | Alarm / trend tracking |

| DO (Dissolved Oxygen) | Biological process indicator | ⚠ Yes (In bio systems) | Key control variable in aeration tanks & fermentation | Aeration blower / valve control |

| Temperature | Condition indicator | ⚠ Sometimes | Affects all chemical equilibria and sensor response | Heating/cooling control loop |

| Residual Chlorine | Disinfection residual | ✅ Yes (Often) | Ensures disinfection and avoids over-chlorination | Dosing control + residual feedback |

| Ammonia / Nitrate | Nutrient removal indicator | ⚠ Sometimes | Used for process optimization in advanced wastewater | Aeration/chemical control |

| Flow Rate | System loading factor | ✅ Yes (Often) | Impacts dosing ratio and chemical consumption | Dosing proportional to flow |

The “3 Layers” Framework for Professionals

To manage water effectively,we are re-classifying water parameters into three practical layers:

- Layer 1:The Outcome(The Goal)-The results you are trying to achieve.

- Layer 2: The Control (The Steering Wheel) – The parameters you can actually adjust.

- Layer 3: The Diagnostics (The Dashboard) – The parameters that check system health.

The Secret: Most operators obsess over Layer 1, but smart professionals know that Layer 2 (pH and ORP) is where the battle is actually won.

Layer 1: The Outcome Parameters (The “Scoreboard”)

Layer 1 includes the critical water quality parameters that define your success or failure. But here is the problem: They are “Lagging Indicators.”

Think of these water quality parameters like the score at the end of a game. When you see the final score, the game is over.

- In Wastewater (The Risk of Fines):COD & Heavy Metals: These water quality parameters tell you if your water is safe to discharge. If your COD sensor triggers an alarm, it is usually too late.

- In Aquaculture (The Risk of Death):Ammonia ($NH_3$): This is the invisible killer. By the time you see fish floating on the surface (the result), the ammonia spike has already happened.

- In Pools (The Risk of Safety):Pathogens (Bacteria): You only know these are high after a lab test 24 hours later. By then, swimmers have already been exposed to unsafe water.

The Trap:You cannot simply “turn a knob” to adjust these outcome-based water quality parameters. To fix the Result (Layer 1), you must control the Cause (Layer 2).

Layer 2: The Control Parameters (Your “Steering Wheel”)

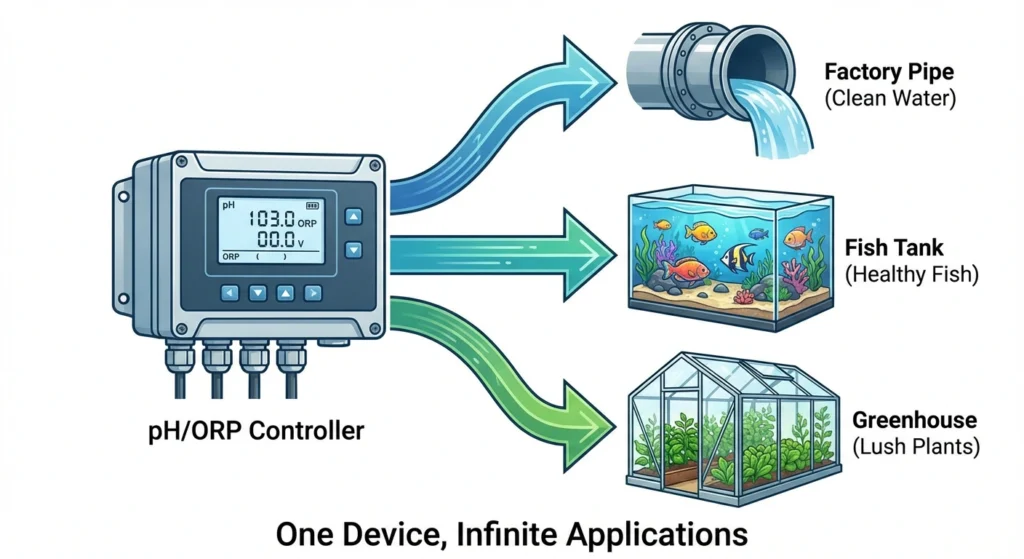

These are the two most important parameters for global water treatment. pH value and ORP are the determining factors for the first layer, whether you are washing water or growing lettuce. These are the settings you should pay attention to.

1. pH: Water Chemistry’s “Gatekeeper”

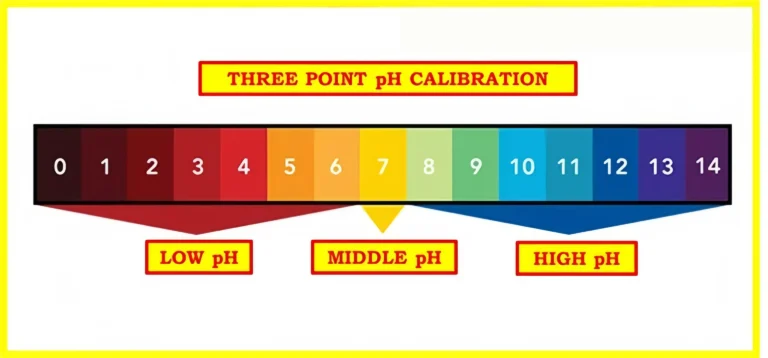

Definition: pH, or Potential of Hydrogen, is a range from 0 to 14 that shows how acidic or basic the water is.

- Neutral is pH 7.

- Less than 7 is acidic pH.

- Basic (alkaline) if pH is greater than 7.

As the “Master Variable,” pH controls the chemicals in the water, including how easily they breakdown and how harmful they are.

| Industry | The Hidden Danger | How pH Controls It |

|---|---|---|

| Wastewater | Heavy Metal Pollution | Metals like Nickel only precipitate (turn into solid sludge) at specific pH levels (e.g., pH > 9.0). If pH drifts, the metals dissolve back into the water. |

| Aquaculture | Ammonia ($NH_3$) | At high pH (> 8.5), harmless Ammonium ($NH_4^+$) transforms into toxic Ammonia ($NH_3$), killing fish instantly. |

| Hydroponics | Nutrient Lockout | If pH is too high or low, plants physically cannot eat the nutrients, causing yellowing and stunted growth. |

| Pools & Spas | Chlorine Efficiency | At pH 8.0, your chlorine is only 20% effective at killing germs. You are wasting money and risking safety. |

The Solution: An [Automated pH Controller] keeps this variable locked in, ensuring safety and compliance 24/7.

2. ORP: The “Truth Teller” of Sanitation

Definition: ORP (Oxidation-Reduction Potential) measures the water’s ability to oxidize contaminants or kill bacteria. It is measured in millivolts (mV).

- High ORP (+mV): High sanitizing power (Clean water).

- Low ORP (-mV): Low sanitizing power (Dirty water).

- ORP is the “Real-Time Health Bar” of your system.

| Application | The Goal | Target ORP Setpoint |

|---|

| Cooling Towers / Pools | Kill Legionella (a deadly bacteria) | > +650 mV (WHO Standard for Safety) |

| Aquaculture (Freshwater) | Healthy Water / Oxidize Waste | +250 to +400 mV (Too high burns fish gills!) |

| Wastewater (Plating) | Cyanide Destruction (Breaking down poisons) | +300 mV to +600 mV (Process specific) |

| Denitrification | Remove Nitrates (Clean Water) | -100 to -300 mV (Negative/Anoxic environment) |

The Professional’s Edge:

While amateurs rely on manual test kits (which are slow), professionals use ORP Controllers to automate dosing. This prevents overdosing (saving money) and under-dosing (preventing disaster).

The Hard Truth About Water Control

Across wastewater treatment, aquaculture, and disinfection systems, one pattern is consistent:

If pH and ORP are stable, most other water quality problems never appear.

- pH controls:

- Chemical solubility

- Toxicity transformation

- Disinfection efficiency

- ORP controls:

- Oxidation strength

- Biological activity

- Pathogen destruction

That is why experienced water professionals do not chase COD, ammonia, or bacteria directly.

They lock pH and ORP first — everything else follows.

You cannot directly control the result.

You can only control the chemistry that creates the result.

Layer 3: The Diagnostic Parameters (Your “Dashboard”)

When pH or ORP becomes unstable, experienced operators do not recalibrate blindly.

They check Layer 3 parameters in a fixed order:

- Step 1: Temperature

- Sudden temperature changes distort pH readings

- High temperature accelerates chemical reactions and electrode aging

- Step 2: Conductivity / TDS

- Rising EC may indicate chemical over-dosing

- Falling EC may signal dilution, leaks, or water source changes

- Step 3: Sensor Health

- Fouled probes cause false control actions

- Uncompensated temperature leads to phantom pH drift

Layer 3 does not control the system —

it explains why the control system is struggling.

Application Scenarios (Mini Case Studies)

Examples of common application scenarios

Here are some frequent circumstances in which water quality measures are used for both monitoring and automatic control:

- Problem: The pH of the influent changes a lot, which could cause it to be released.

- Solution: An online pH controller and a pump for adding acid and alkali

- The result is a stable discharge pH and reduced chemical waste.

- Challenge: Changes in ORP affect how well chlorine works and how stable disinfection is.

- The ORP control loop modifies the dose based on how much oxidation is needed to fix the problem.

- Result: More even disinfection and a lower risk of over-chlorination.

- Aeration energy is expensive, and too much DO wastes electricity.

- Answer: The DO sensor and controller modify the speed of the blower by themselves.

- Outcome: Less energy use and constant biological performance

Sino Inst provides integrated pH/ORP controllers that allow PID control and have multiple output options (relay/4–20mA/RS485), so you can easily link them to dosing pumps and PLC systems.

Conclusion:Stop Guessing,Start Controller

You cannot control the weather,and you cannot predict every production shock load.But you can control your pH and ORP.

If you are still relying on manual testing or waiting for lab results on”Lagging Indicators”like COD,you are gambling with your compliance.By the time you find a problem.

The solution is simple:Stabilize your system at the source.Automate the “Control Layer”,and the results will follow.

FAQ

Related Products

pH/ORP Controllers

Glass Sensor

Plastic-Shell Sensor

Ready to upgrade your peace of mind?

Don’t risk a fine to save a few dollars. Shop our [Industrial pH & ORP Controllers] today. Reliable, precise, and built to keep your water quality parameters perfect, 24/7.

Request a Quote

More Resources

-

How Do You Test for Helium?

Helium is a unique element. It is the second lightest element in the universe, chemically inert, non-flammable, and possesses the smallest atomic size…

-

How Do I Get My Carbon Monoxide Detector to Stop Chirping? (2026 Guide)

The piercing sound of a carbon monoxide (CO) detector chirping is one of the most stressful noises a homeowner can experience. It often…

-

Choosing a pH Meter for Water:The Professional Guide to(2026)

A pH meter for water is the pulse of chemical equilibrium in water treatment and industrial processing, far more than just a digital…

-

9 Best Personal Gas Monitoring Devices 2026

In the industrial world, safety is not a luxury; it is a prerequisite for operation. As we move into 2026, the technology driving…

-

What Is Dissolved Oxygen in Water? The Ultimate Guide to Monitoring(2026)

When we talk about water quality, we often focus on what we can see, like clarity, or what we can taste, like salt….

-

Mastering Safety: How to Check Gas Level in Confined Space?

The Critical Importance of Atmospheric Testing Working in industrial environments often requires entering areas that are not designed for continuous occupancy. These locations,…

.png)