With its core design features such as a PTFE shell, anti-fouling interface, and solid gel salt bridge, the GRT1020J pH electrode combines the advantages of resistance to organic solvents, prevention of electrode poisoning, and low maintenance, making it a practical choice for pH monitoring of various complex water qualities. It can be adapted to a variety of pH meters, providing accurate and stable pH data support for scenarios such as wastewater treatment.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| Measurement Range | 0-14 pH |

| Material | PTFE |

| Temperature Range | 0-100℃ |

| Pressure Range | 0-0.3M Pa |

| Sheath selection | 0-3 meter submerged sheath (PVC) |

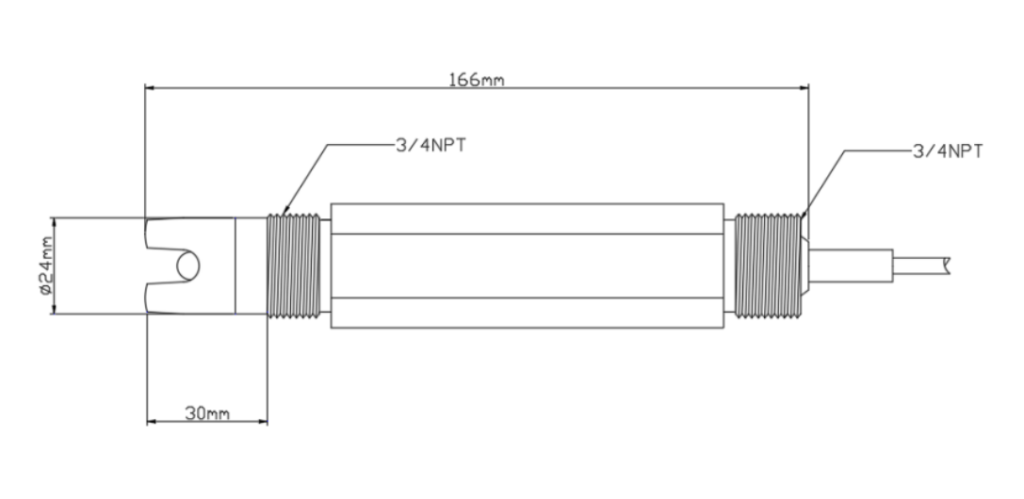

| Thread Size | 3/4 inch NPT |

| Zero Potential | 7±0.5 |

| Cable length | Standard configuration of 3 meters, optional with temperature compensation |

| Applications | Suitable for industrial wastewater, acid-base neutralization, water containing organic solvents |

Scope of application

- The electrode can be used with various pH meters and is suitable for online wastewater detection;

- The electrode’s lifespan is six months under normal use, but harsh environments or improper maintenance will shorten its lifespan.

Core Product Advantages

- Organic solvent corrosion and complex chemical wastes don’t foul the electrode’s PTFE casing. Ring-shaped PTFE liquid connectors prevent clogging and minimize cleaning time for long-term online continuous detection.

- Solid gel dielectric salt bridges are easy to use since they don’t need to be replaced, which means less work every day. Under normal settings, keeping S²⁻, CN⁻, and other ions from poisoning the electrode can make it last for six months.

- Versatile and quick: Featuring electrode-sensitive membranes, it monitors pH 0-14 and temperature 0-100℃. The electrode has low internal resistance, fast response, stability, and a theoretical slope of ≥95%, ensuring accurate detection data.

- Installation is simple with standard interface. Terminal block connections use 3/4-inch threads. Choose a sheath tube or cable tie for installation. Suitable for most industrial testing equipment. Well-defined wiring ensures signal stability.

Scope of Application

Testing for industrial wastewater: This is mostly used to check the pH of different types of industrial and municipal wastewater online. It works best for chemical desulfurization wastewater and electroplating mixed wastewater that include interfering ions like S²⁻ and CN⁻. It can run for a long time without any problems and make sure the data is correct.

Organic solvent media scenarios: Suitable for pH monitoring of process fluids containing organic solvents (such as ethanol extract and acetone reaction mother liquor) and organic wastewater in the pharmaceutical and fine chemical industries. The PTFE shell can resist solvent corrosion.

Medium and high temperature water sample testing scenarios: It can handle pH measurement of medium and high temperature water quality such as dyeing and printing wastewater and papermaking black liquor at 60-100℃, and maintains low internal resistance and fast response detection performance within the rated temperature range.

General water quality control scenarios: Used for electrochemical monitoring of circulating cooling water in the power and metallurgical industries, as well as full-range pH monitoring of integrated wastewater treatment plants in industrial parks, to ensure process stability and equipment safety.

Usage, maintenance and precautions

Cleaning and Maintenance:

The sensor surface must be kept clean. If the antimony electrode surface becomes dark due to oxidation or has stains, gently polish it with fine sandpaper to remove the surface oxide layer and stains, restoring the sensor’s detection sensitivity. Be careful with the wiping pressure; apply light pressure to avoid damaging the electrode itself.

Contraindications:

If heavy metals or other ions that can form metal coatings or complexes with antimony are present in the solution being tested, this electrode cannot be used. In addition to producing erroneous test results, these substances will chemically react with the electrode, causing irreparable damage and drastically reducing its lifespan.

Putting in waterproofing

Use matching sheathing tubing or wire harness during installation to make sure it is done correctly. Since the connection between the sensor wire and the sensor isn’t waterproof, make sure to use special waterproof tape or sealant to seal this region well so that moisture can’t get in and short circuits or performance problems don’t happen in the internal parts.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

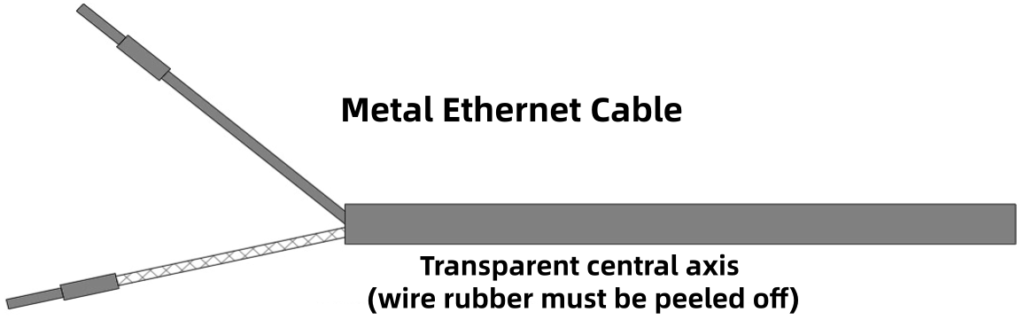

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

As a professional pH electrode specifically designed for online wastewater monitoring, the GRT1020J effectively meets the monitoring needs of various scenarios, including industrial wastewater, organic solvent media, and medium-to-high temperature water samples, thanks to its excellent anti-interference capabilities, user-friendly operation and maintenance, and stable detection performance. As long as proper installation and regular maintenance are followed, its performance advantages can be fully realized, ensuring the continuity and accuracy of monitoring work.

Request a Quote

.png)