Choosing the right ph meter electrodes is critical for industrial uptime. Whether you are dealing with high-solids slurries or toxic effluents, a standard laboratory ph electrode will fail within days. This guide explores the most durable ph sensor electrode options designed to withstand the harshest 2026 industrial environments.

Why Plastic pH Electrodes Outperform Glass in Industrial Water Treatment

The survival of an industrial or wastewater pH electrode determines its value.

Working with high-solids slurries, caustic chemicals, or hazardous effluents has likely caused the following issues:

- Frequent tiny liquid junction clogging

- Reference sulfide/cyanide poisoning

- Broken glass bulbs from pressure or turbulence

- Due to severe temperatures and pressures, leaks or failure

These failures lead to unstable readings, unplanned downtime, and costly sensor replacements.

Insert Plastic-Shell Electrode.

Plastic pH electrodes made of Epoxy, PPS, or PVDF are designed like industrial gear, not delicate laboratory glassware. Advantages include:

- Housing that resists impact

- Wide-temperature performance

- Anti-poisoning double- or triple-junction designs

- Replaceable salt bridges

- Anti-fouling PTFE joints

Below is a detailed comparison of the Top 5 Plastic pH Electrodes designed specifically for harsh industrial and wastewater applications.

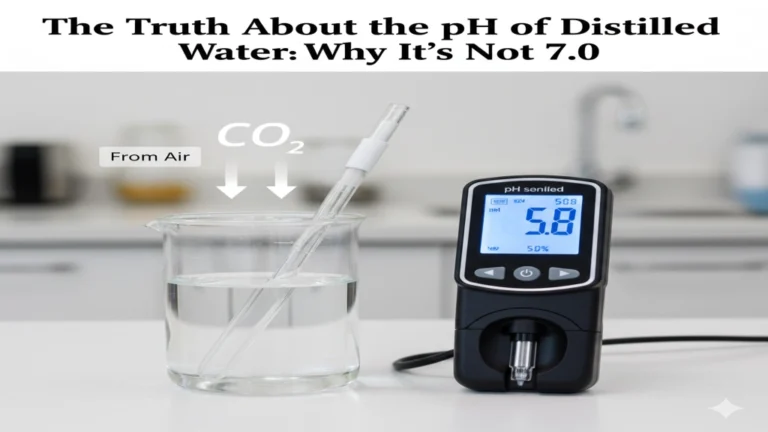

How does pH electrode work?

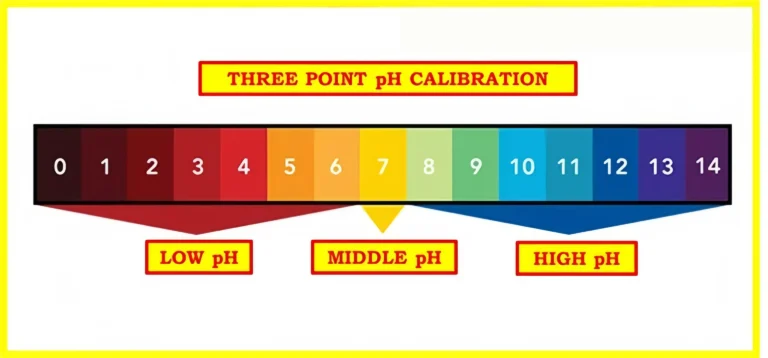

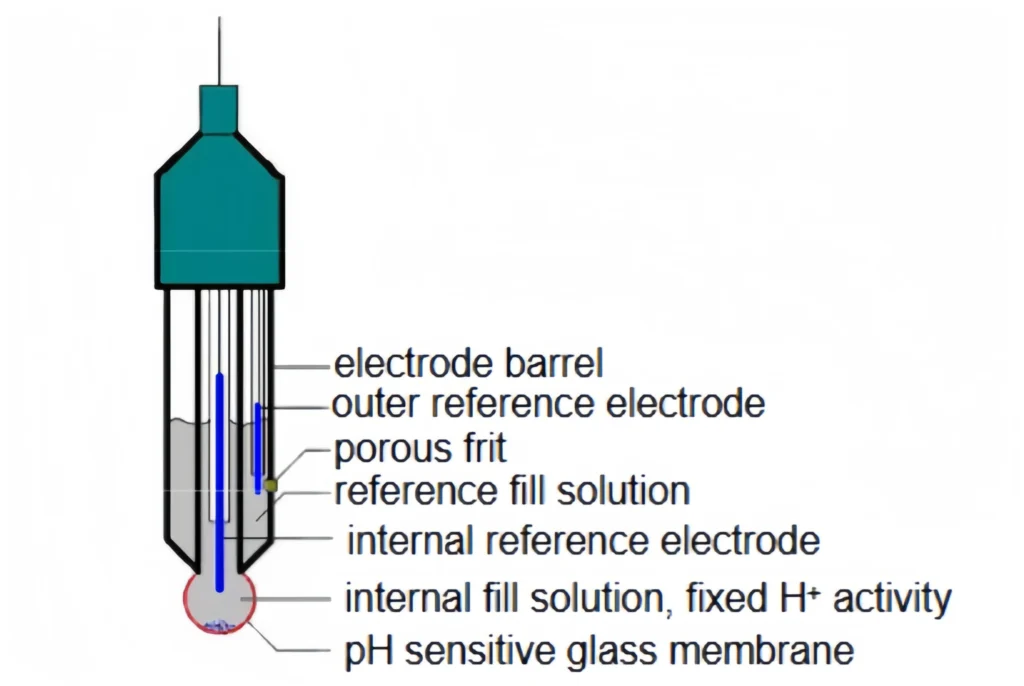

A pH electrode works like a ‘chemical battery’. The voltage signal is generated by monitoring the activity of hydrogen ions ($H ^+$) in water. Its basic logic:

- Membranes sense: Hydrogen ions in the water sample exchange with the glass ball (Sensitive Membrane) at the top of the electrode, causing a potential difference inside and outside the membrane.

- Comparison: A continuous “reference voltage” is provided by a reference electrode inside the electrode to read this voltage.

- To convert voltage, the transmitter measures the difference between these potentials. At 25 ° C, the Nernst equation states that the electrode changes 59.16 mV per pH unit.

- We see 0-14 pH values because the device translates the millivolt (mV) data.

Quick Comparison: Top 5 Plastic Electrodes at a Glance

Short on time? Use this table to find the specific sensor model that fits your industrial application.

|

Product Model |

Core strengths |

temperature tolerance |

Adaptation scenario |

Core technology |

|---|---|---|---|---|

|

GRT1320PDW |

High temperature and high pressure+differential anti-interference+replaceable salt bridge |

0-130℃ |

Pharmaceutical high-temperature sterilization, chemical reaction kettle, beer fermentation |

Three electrode differential structure, high temperature resistant gel dielectric |

|

GRT1030JW |

Anti toxic and anti blocking+wide temperature and low maintenance+data compliance |

0-130℃ |

Municipal sewage, chemical sulfur-containing/cyanide containing wastewater |

Circular PTFE liquid interface, preventing S ² ⁻/CN ⁻ poisoning |

|

GRT1020PD |

Short size+medium low temperature differential+economical and practical |

0-60℃ |

Pharmaceutical pilot testing, small-scale reaction vessels, food wastewater |

159mm short body, differential anti electromagnetic interference |

|

GRT1030W |

High cost-effectiveness+adaptation to normal working conditions+basic anti-virus |

0-60℃ |

Small and medium-sized electroplating plants, township sewage stations |

No need to replenish charging medium, easy maintenance |

|

KPT-561FW |

Strong corrosion resistance+customization+low attenuation |

0-130℃ |

Fluorine containing wastewater, high concentration acid-base chemical wastewater |

Perfluorinated shell, corrosion-resistant sensitive film |

Top 5 in-depth analysis of products

GRT1320PDW

Best for High-Temp & High-Pressure

Key Specifications:

- Application: WWTP Aeration Tanks, Deep Wells, River Monitoring.

- Protection: IP68 Submersible Standard.

- Junction: Double Junction for extended life.

Core strengths:

| Parameter | Value |

|---|---|

| pH Range | 0-14 pH |

| ORP Range | -1500—+1500 mV |

| Sensitivity | pH:±0.01pH ORP:±0.5mV |

| Temperature Range | 0-130℃ |

| Pressure Range | At 130 ℃, it is 4 bar |

GRT1030JW

Highly toxic wastewater specific electrode

Key Specifications:

- Application:Suitable for online detection of sewage

- No need to replenish electrolytes

- Adopting PTFE liquid interface, it is not easy to block

Core strengths:

| Parameter | Value |

|---|---|

| pH Range | 0-14 pH |

| Pressure resistance | 0-0.3MPa |

| Zero potential | 7±0.5 |

| Temperature Range | 0-130℃ |

| Theoretical percentage slope | ≥ 95% |

| Thread Size | 3/4 inch NPT |

GRT1020PD

Compact Anti-Interference pH Electrode

Key Specifications:

- Differential technology, precise anti-interference

- Swap salt bridge, extend lifespan

Core strengths:

| Parameter | Value |

|---|---|

| pH Range | 0-14 pH |

| ORP Range | -1500—+1500 mV |

| Sensitivity | pH:±0.01pH ORP:±0.5mV |

| Temperature Range | 0-60℃ |

| Pressure Range | 4 bar |

KPT-561FW

Corrosion-Resistant pH Electrode for Sewage Monitoring

Key Specifications:

- Circular PTFE liquid interface

- No need to replenish electrolytes

- Adopting PTFE liquid interface, it is not easy to block

- Installation interface

3/4-inch NPT Thread

Core strengths:

| Parameter | Value |

|---|---|

| Measurement Range | 0-14 pH |

| Theoretical percentage slope | ≥95% |

| Zero potential | 7±0.5 |

| Temperature Range | 0-130℃ |

| Pressure Range | 0-0.3 M Pa |

| Body Material | PVDF |

| Thread Size | 3/4 inch NPT |

| Junction / Electrolyte | PTFE ring junction + solid gel electrolyte |

Plastic vs. Glass Electrodes-Which Lasts Longer in Wastewater?

In harsh industrial and wastewater environments, “ruggedness” directly determines electrode service life and maintenance costs. Below is a side-by-side comparison of plastic and glass electrodes in key durability metrics—proving why plastic is the smarter choice for tough, dirty conditions:

| Ruggedness Metric | Plastic Electrodes (Our Top 5) | Glass Electrodes |

|---|---|---|

| Impact Resistance | Withstand debris impact & pump turbulence | Break easily under mechanical stress |

| Chemical Resistance | PPS/PVDF resist acids, alkalis, solvents | Vulnerable to HF, strong alkalis |

| Fouling Resistance | PTFE/ceramic junction reduces clogging | Narrow glass junction clogs quickly |

| Service Life in Wastewater | 4-12 months | 1-3 months |

| Maintenance | Gel electrolyte, minimal servicing | Frequent calibration + careful handling |

Key Takeaway: For rugged industrial/wastewater use, plastic electrodes outperform glass in every durability category. They eliminate costly downtime from breakage, corrosion, and clogging.

How to choose the appropriate plastic sensor

Quickly match suitable sensors based on 5 core factors to avoid over specification or mismatch:

- Medium Characteristics

- Strong acids/alkalis → PVDF models

- High solids (≥3000 mg/L) → Anti-clog PTFE junction

- Light-duty chemicals → Epoxy/PC body

- Environmental Conditions

- Temperature >80°C → High-temperature series

- High turbulence or pump agitation → Reinforced PPS/PVDF

- Required Accuracy

- Process control → ±0.02 pH

- General monitoring → ±0.05 pH

- Installation Compatibility

- Pipes → 3/4″ NPT

- Tanks → Submersible IP68

- Controllers → BNC or custom S8 connector

- Cost vs. Lifespan

- Consider “cost per month,” not purchase price.

- PVDF → 10–12 months life

- Polycarbonate → 4–6 months life

- Consider “cost per month,” not purchase price.

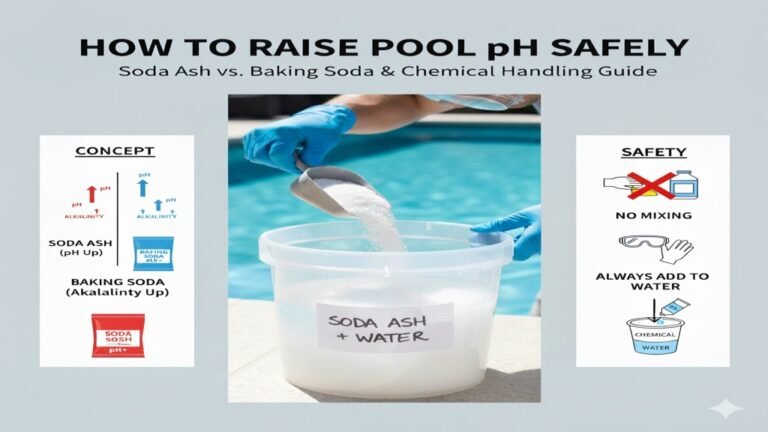

Maintenance Tips: Keep Your Plastic Sensor Alive

Even the most durable plastic sensor needs care. Follow these 3 golden rules:

- Never Store Dry: Always keep the protective cap filled with 3M KCl solution. A dry bulb means a dead sensor.

- Clean Gently: For plastic bodies, you can use a soft brush and mild detergent to remove sludge. For scale buildup on the GRT1030W, a quick dip in 5% HCl is effective.

- Watch the Slope: Calibrate weekly. If the slope drops below 85% even after cleaning, the reference system is likely depleted, and it’s time for a replacement.

FAQ

Related Products

Ready to Upgrade Your Industrial pH Measurement System?

Choosing the right plastic pH electrode dramatically reduces:

- Clogging

- Drift

- Poisoning

- Breakage

- Operating costs

If you need help selecting a model or integrating sensors into your process control system, our engineering team can assist.

Request a Quote

More Resources

-

Is It Safe to Drink Purified Water? Practical Guide to Making a Healthy Choice.

Is it safe to drink purified water? “Is the most crucial question for health conscious consumers when choosing bottled water or home water…

-

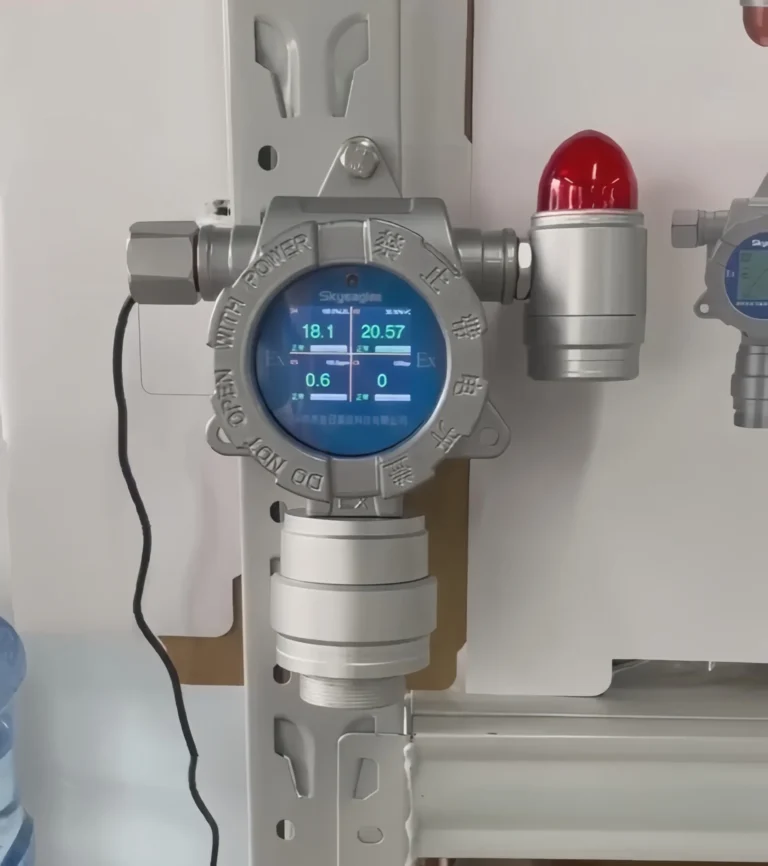

5 Kinds of Detector Detects Gas Leaks: Expert Selection Guide

In industrial safety, the margin for error is non-existent. Whether managing a petrochemical refinery, an agricultural greenhouse, or a manufacturing plant, the ability…

-

Total Chlorine vs Free Chlorine: The Complete Industrial Monitoring Guide (2026)

Introduction:Why the Chlorine”Guess”Costs You Money? In water treatment,precision isn’t just a goal;it’s a safety requirement.Many operators ask:”Is total chlorine vs free chlorine same?“The…

-

5 Expert Tips to Put an Explosive Gas Detector for Maximum Safety

Safety is not a variable; it is a constant requirement in industrial process control. When dealing with combustible gases, the difference between a…

-

9 Best VOC Detectors for 3D Printing Safety (2026 Guide)

As 3D printing technology moves from industrial factories to home workshops and small businesses, air quality safety has become a paramount concern. Whether…

-

What Does Muriatic Acid Do for a Pool?(2026)

Maintaining a crystal-clear swimming pool is a balancing act of chemistry. Among all the chemicals in a pool professional’s kit, muriatic acid is…

.png)