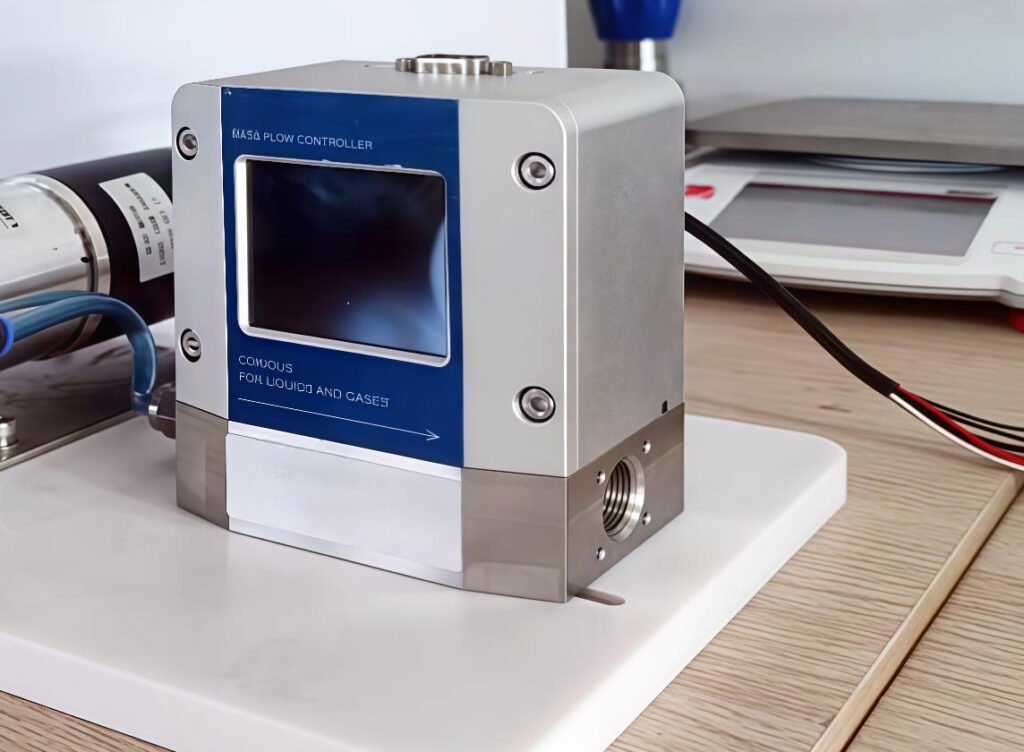

SI-20FEH Split-type Mass Flow Controller/Flow Meter is a Coriolis mass flow controller. It can withstand temperatures as low as -196℃ and can measure a minimum flow rate of 0.05 g/h.

This mass flow meter/controller utilizes the Coriolis principle, allowing direct measurement of mass flow rate unaffected by other fluid characteristics. Unlike other large-scale Coriolis flow meters, this Coriolis mass flow meter excels in the precise measurement and control of small flow rates and has been successfully applied in various scientific research experiments and industrial production.

★★★★★

Benefits

- High Precision and Repeatability

The SI-20FEH Mini Coriolis Mass Flow Meter achieves high-precision measurement. It boasts high resolution, capable of measuring minute flow rates, down to 0.05 g/h, with an accuracy of 0.25%~0.5% F.S., and liquid measurement accuracy reaching ±0.25% F.S. The measurement ratio can reach up to 100:1. It effectively eliminates measurement errors and possesses excellent repeatability, providing users with stable and reliable flow data.

- Corrosion Resistance

The SI-20FEH Mini Coriolis Mass Flow Meter maintains long-term stable performance when handling corrosive media, unaffected by media corrosion, significantly extending its service life and effectively reducing measurement deviations caused by contamination.

Its excellent corrosion and contamination resistance makes it widely used in industrial scenarios requiring the handling of corrosive or contaminated fluids, such as chemical, petroleum, semiconductor processing, pharmaceutical, and various instrumental analyses.

- Low Temperature Resistance

The SI-20FEH mini Coriolis mass flow meter is capable of withstanding low temperatures, operating stably even at -196℃, continuously providing accurate and reliable flow data to help users achieve process control and production optimization.

- Wide Measurement Range

It covers a wide range of flow rates from micro to medium-to-large flow rates, specifically including:

- Low range: 0~(20g/h~50kg/h)

- Medium range: 0~(50kg/h~100kg/h)

- Large range: 0~(100kg/h~300kg/h)

- Ultra-large range: 0~(300kg/h~1000kg/h)

It is suitable for high-precision measurement needs under different flow conditions.

- Good Adaptability

The Coriolis mass flow controller/meter is unaffected by the physical properties of the fluid and can meet the needs of various fluid applications. Suitable for various gases (such as air, nitrogen, oxygen, etc.) and liquid media (including water, oils, organic solvents, etc.), exhibiting good versatility and stability.

- Communication Signals

Designed to meet the needs of online monitoring and control in industrial settings, it supports multiple standard signals, including analog signals (4~20mA/0~5V) and digital communication interfaces (such as RS232/RS485, Profibus-DP, DeviceNET protocols, etc.). It enables remote high-precision data acquisition and flow control, allowing users to select the appropriate interface based on specific application requirements and environmental conditions.

Specifications

| Product | SI-20FEH | |||||||||

| Model | SC | SM | LC | LM | MC | MM | BC | BM | HC | HM |

| Measuring range | 0-(20g/h-25kg/h) | 0-(20g/h-50kg/h) | 0-(50kg/h-100kg/h) | 0-(100kg/h-300kg/h) | 0-(300kg/h-1000kg/h) | |||||

| Accuracy | ±0.8%F.S | Gases: ±0.5.0% F.S; Liquids: ±0.25.0% F.S | ||||||||

| Linearity | ±0.1%F.S | |||||||||

| Repeatability | ±0.05%F.S | |||||||||

| Maximum withstand pressure | 3MPa/10MPa | |||||||||

| Range ratio | 50:1 | 100:1 | 50:1 | 100:1 | 50:1 | 100:1 | 50:1 | 100:1 | 50:1 | 100:1 |

| Analog signal | 0~5V、4~20mA | |||||||||

| Digital signal | RS232/485, MODBUS protocol | |||||||||

| Power supply | 24VDC | |||||||||

| Communication protocol | Modbus、DeviceNet、profinet、ErtherCAT、profibus | |||||||||

| Operating temperature | 0~70℃, High/low temperature media temperatures can be customized. | |||||||||

| Maximum withstand pressure | 3MPa/10MPa (specify when ordering) | |||||||||

| Electrical connection | DB9 port | |||||||||

| Display screen | Touchscreen display | |||||||||

| Leakage rate | 2×10⁻⁹ Pa·m³/s | |||||||||

| Protection class | IP40 | |||||||||

| Valve | Valve normally closed | / | Valve normally closed | / | Valve normally closed | / | Valve normally closed | / | Valve normally closed | / |

| Base material | Stainless steel | |||||||||

| Mounting location | Installation in any position | |||||||||

| Sealing material | Fluororubber, nitrile rubber, EPDM, perfluoroelastomer | |||||||||

| Connector | Foldings, pagoda fittings, quick-connect fittings, VCRs, flanges, etc. | |||||||||

Performance and Principle

Coriolis mass flow controllers are highly regarded for their measurement accuracy and insensitivity to fluid properties.

The SI-20FEH incorporates a uniquely shaped single-loop sensor as part of an oscillating system. When fluid flows through the sensor loop, the Coriolis force induces a variable phase shift. The sensor detects this phase shift and transmits it to a DSP processor on an integrated circuit board for processing. The resulting output signal from this variable phase shift is strictly proportional to the actual mass flow rate, achieving unparalleled performance even under varying conditions such as pressure, temperature, density, conductivity, and viscosity.

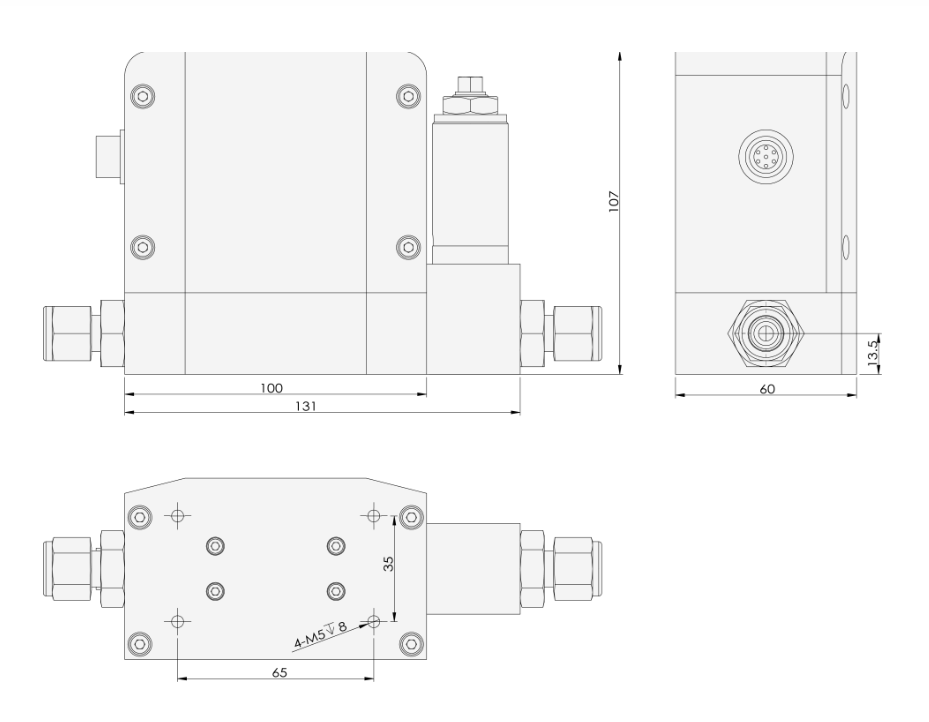

For applications measuring high- or low-temperature fluids, a split-type design is used, simultaneously measuring and outputting mass flow rate, fluid density, and temperature.

The SI-20FEH instrument can be applied to process fluid measurement or control systems in the food, (petro)chemical, and pharmaceutical industries, fermentation equipment, semiconductor processing, and fuel cell technology.

Cryogenic Liquid Nitrogen Micro-Flow Measurement

With the deep penetration of liquid nitrogen technology into aerospace, biomedicine, and high-end manufacturing, the precision of sample storage and process control in ultra-low temperature environments has become a core industry requirement. However, traditional monitoring methods have long faced the following bottlenecks:

Conventional mass flow meters only support a temperature range of -40℃ to +80℃, failing to meet the stable operation requirements at the boiling point of liquid nitrogen (-196℃);

Some flow meters operate in such special environments for extended periods, and the drastic temperature differences between the inside and outside of the storage tank can easily lead to a significant decrease in measurement accuracy or data drift. This can cause flow meter malfunction, resulting in inaccurate measurements, production interruptions, and significant losses.

To address the challenges of these harsh operating conditions, Sino-Inst, leveraging over a decade of experience in fluid measurement and control technology, offers a solution: the SI-20FEH-LM small-flow Coriolis mass flow meter.

This independently developed and manufactured mass flow meter utilizes the Coriolis principle, directly measuring mass flow rate without being affected by other fluid characteristics. Unlike other large-scale Coriolis flow meters, this Coriolis mass flow meter excels in the precise measurement and control of small flow rates and has been successfully applied in various scientific research experiments and industrial production.

With the increasing demand for cryogenic medium flow measurement and control, we have optimized and expanded the performance of the SI-20FEH-LM Coriolis mass flow meter. It can now withstand temperatures down to -196℃. Combined with a remote control system, it enables precise measurement of cryogenic fluids and can continuously or intermittently output instantaneous or cumulative flow rates.

Technical Support

How Does a thermal mass flow controller working principle?

8 Best Mass Flow Controller Manufacturers

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

Guide to Connecting a Thermal Mass Flow Controller to a PLC

The technological advantages of the SI-20FEH miniature Coriolis mass flow meter and its application in cryogenic liquid nitrogen measurement and control not only demonstrate our expertise in precision measurement and cryogenic engineering but also highlight our commitment to continuously creating value for our customers.

Sino-Inst specializes in manufacturing gas/liquid mass flow meters and controllers. Designed according to customers’ actual operating conditions and needs, our products are widely used in various industries for the precise measurement and control of gas/liquid mass flow rates.

Request a Quote

Related Products

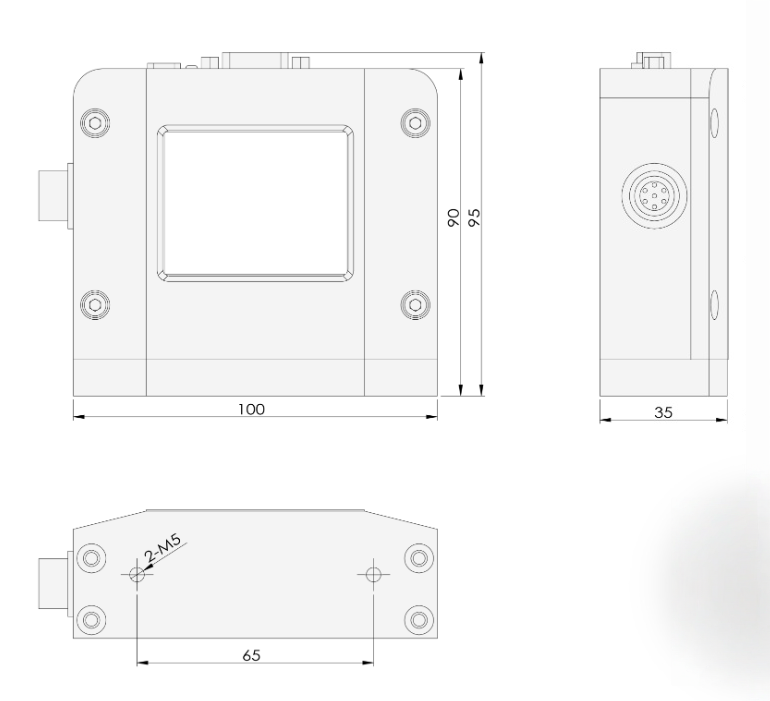

Mass Flow Controller/Meter for Micro Flow-Low Temp Split-type

SI-20FEH Split-type Mass Flow Controller/Flow Meter is a Coriolis mass flow controller. Can withstand -196°C. The minimum measurable flow is 0.05 g/h.

Product SKU: SI-20FEH Mass Flow Controller/Flow Meter for Micro Flow - Low Temperature

Product Brand: Sino-Inst

Product In-Stock: InStock

5

.png)