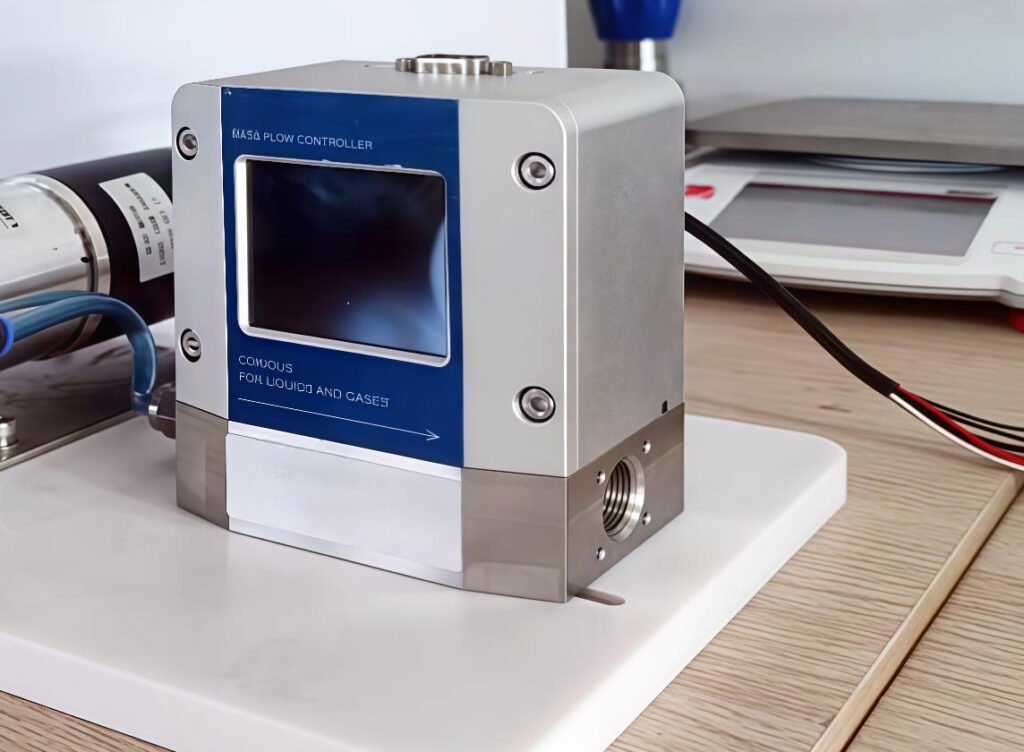

The SI-10FD Digital Mass Flow Controller/Meter is based on thermal mass flow measurement technology, combined with advanced digital signal processing and control algorithms, and supports RS232/485 and MODBUS protocols.

When used with your company’s mass flow measurement and control system, it can control solenoid valves. Parameters can be adjusted according to different operating conditions to achieve fast and accurate flow control. The user interface is user-friendly and easy to operate. Customized functions can also be provided according to customer needs.

★★★★★

Features

Specifications

| Model | SI-10FD-LM; SI-10FD-LC | SI-10FD-MM; SI-10FD-MC | SI-10FD-BM; SI-10FD-BC |

| Measurement Range | 2SCCM~30SLM (low range) | 30SLM~300SLM (medium range) | 300SLM~3000SLM (high range) |

| Control Range | Range ratio 100:1; Controller valve control range 50:1 | ||

| Accuracy | ±1.0% F.S | ||

| Linearity | ±0.5% F.S | ||

| Repeatability | ±0.2% F.S | ||

| Response Time | <0.8s | ||

| Digital Inputs | RS232/485, MODBUS protocol | ||

| Analog Inputs | 0–5V, 4–20mA, 1–5V | ||

| Power Supply | ±15VDC, 24VDC | ||

| Operating Temperature | 0–50℃ | ||

| Operating Pressure | Operating pressure drop: <0.01 MPa | ||

| Maximum Pressure Rating | 3 MPa/10 MPa | ||

| Electrical Connections | DB15 connector | ||

| Leak Rate | 1×10⁻⁹ Pa·m³/s | ||

| Temperature Coefficient | ±0.025% F.S./°C | ||

| Base Material | Stainless steel | ||

| Seal Material | Fluorocarbon rubber, neoprene, nitrile rubber | ||

| Connectors | φ3, φ6, 1/8″, 1/4″, φ8, φ10, φ12, flange mounting | ||

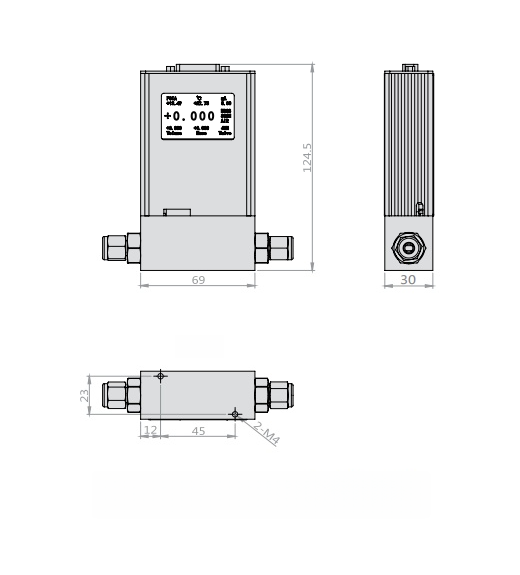

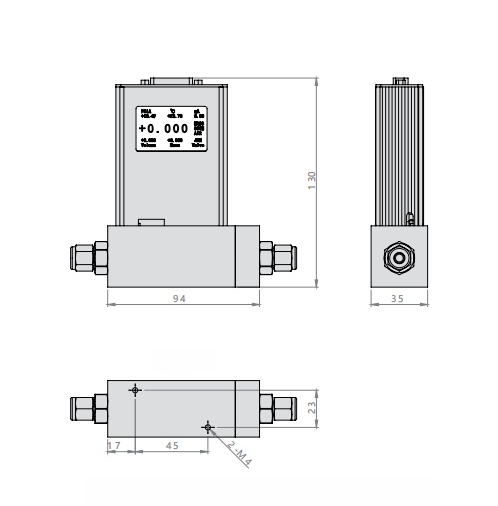

Dimensional diagrams of SI-10FD-LM Digital Mass Flow Meter

Dimensional diagrams of SI-10FD-LM Digital Mass Flow Meter SI-10FD-LC Digital Mass Flow Controller Dimension

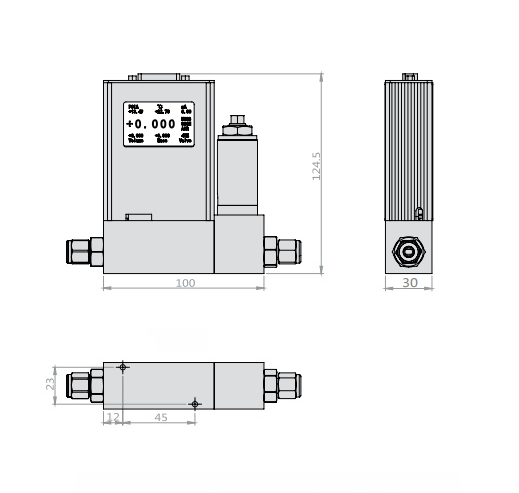

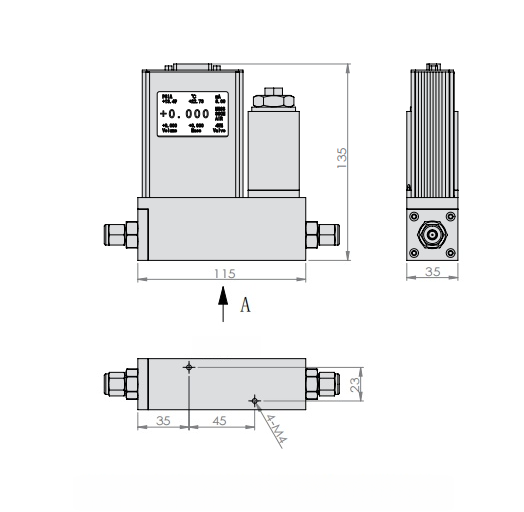

SI-10FD-LC Digital Mass Flow Controller Dimension SI-10FD-MM Digital Mass Flow Meter Dimension

SI-10FD-MM Digital Mass Flow Meter Dimension SI-10FD-MC Digital Mass Flow Controller Dimension

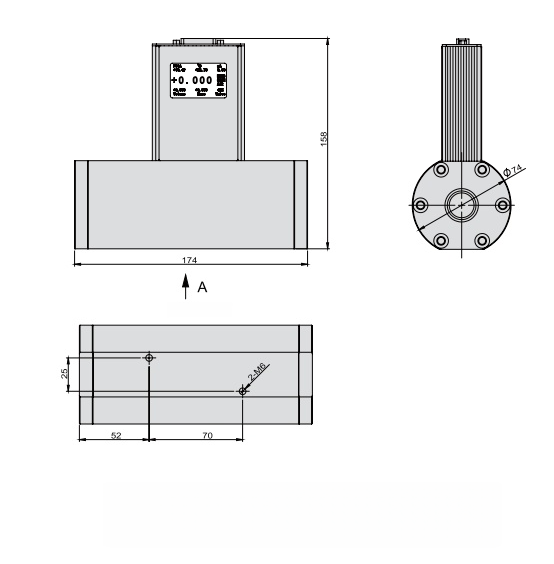

SI-10FD-MC Digital Mass Flow Controller Dimension SI-10FD-BM Digital Mass Flow Meter Dimension

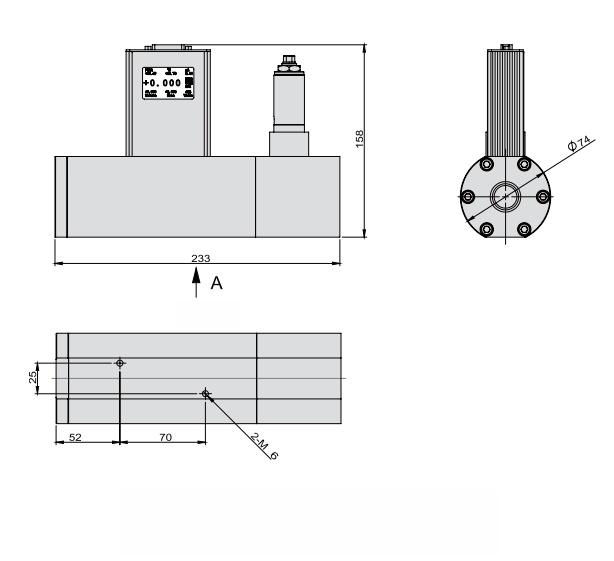

SI-10FD-BM Digital Mass Flow Meter Dimension SI-10FD-BC Digital Mass Flow Controller Dimension Drawing

SI-10FD-BC Digital Mass Flow Controller Dimension Drawing

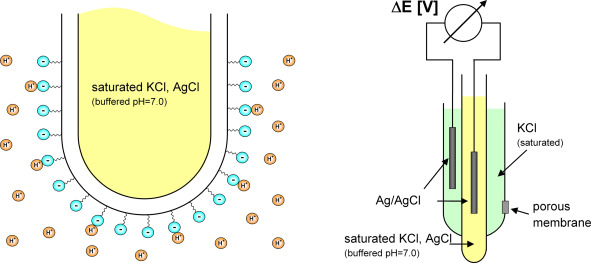

Digital Mass Flow Controller/Meter Working Principle

The Digital Mass Flow Controller/Meter operates based on thermal mass flow measurement technology, combined with advanced digital signal processing and control algorithms. Through a built-in heating element and temperature sensor, it accurately measures the heat carried away by the fluid, thereby calculating the fluid’s mass flow rate.

When the fluid flows through the sensor, it changes the sensor’s temperature distribution, and this temperature change has a definite functional relationship with the fluid’s mass flow rate.

The microprocessor in MFC performs rapid calculations based on the measured temperature signal, converting the flow data into a digital signal and comparing it with a preset flow value. Once a deviation between the actual flow rate and the target flow rate is detected, the controller immediately adjusts the valve opening. By changing the cross-sectional area of the fluid flow, it precisely controls the flow rate, quickly stabilizing it at the set value. The entire process is responsive and highly accurate, with errors controlled within a very small range, meeting the stringent flow control requirements of various applications.

Applications of the Digital Mass Flow Controller/Meter

The SI-10FD Digital Mass Flow Controller/Meter measures the mass flow rate of gases using the principle of capillary heat transfer temperature difference calorimetry, unaffected by changes in ambient temperature and pressure.

Application Areas:

- Semiconductor Manufacturing: Precisely controlling the flow rate of process gases during etching, deposition, and doping processes.

- Chemical Vapor Deposition (CVD): Used in the manufacture of optical fibers, solar cells, and other high-tech products.

- Food Processing: Controlling the gas mixing ratio in food packaging, such as adjusting the gas composition in air-conditioning packaging.

- Bioreactors: Precisely controlling the flow rate of oxygen and nutrient gases input to bioreactors.

- Environmental Monitoring: Using DMFC to ensure accurate measurements in air quality monitoring and emission control.

Also applicable to the glass industry, solar energy, atmospheric monitoring, industrial manufacturing, oil and petrochemicals, coal, metallurgical gas distribution, environmental protection, and various instrumental analyses.

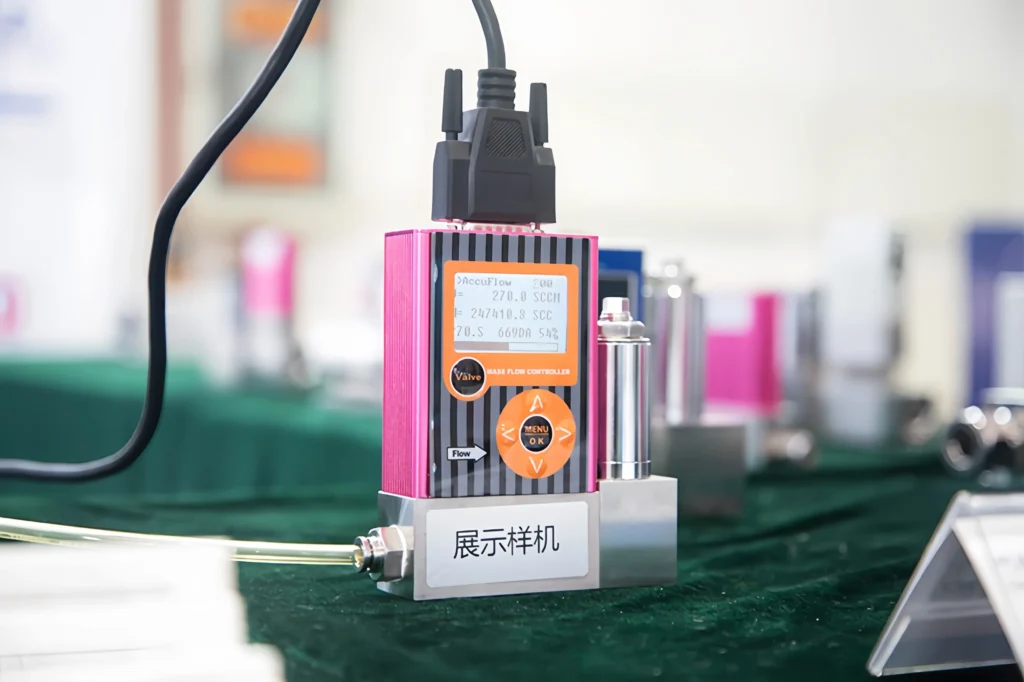

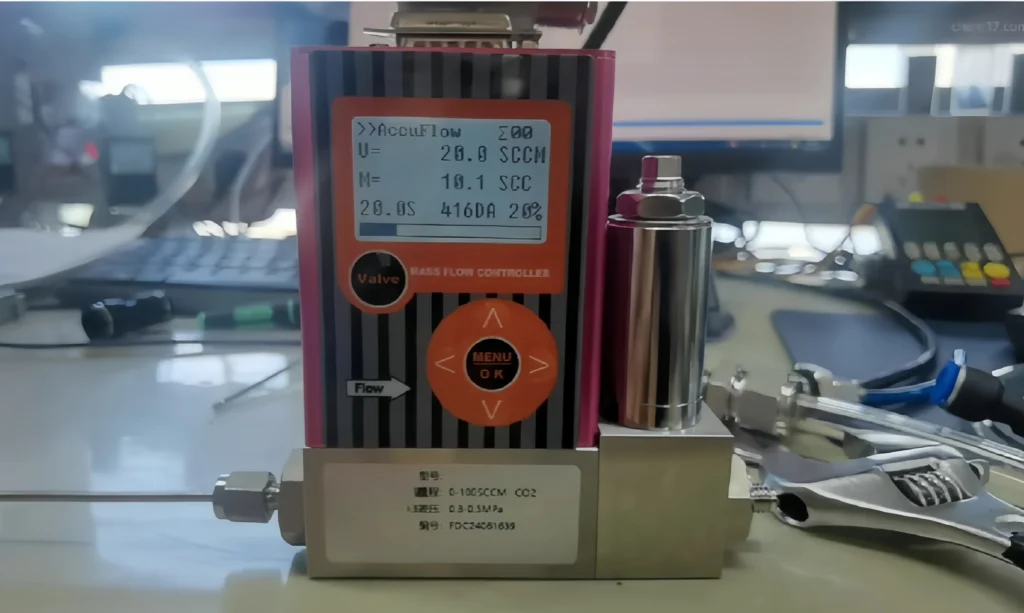

User Case:

A certain heat treatment equipment company specializes in the research and production of equipment for ion nitriding processes. Its main products include the LD series ion nitriding furnaces, the LDMC series pulse ion nitriding furnaces, and ion nitriding furnaces with auxiliary heating.

Their gas supply system consists of an ammonia cylinder, an ammonia pressure regulator, a gas mass flow meter, and gas pipelines. Two flow meters are required, one for regulating the ammonia flow and the other for regulating the carburizing gas flow. The two gases are mixed after passing through the flow meters before entering the furnace. By adjusting the flow ratio, a carbonitriding process (soft nitriding) can be achieved.

Solution: Based on the process requirements of this product, our company customized the SI-10FD series gas mass flow meter for this enterprise. After successful installation on the equipment, it is unaffected by temperature, pressure, or other conditions, accurately controlling the flow rates of both gases with high sensitivity and fast response. It achieves the proportional mixing of the two gases, thereby improving the carbonitriding process, earning high praise from the customer and establishing a long-term cooperative relationship.

Multi-MFC Integrated Monitoring and Control

In practical applications, users often need to remotely monitor and control multiple gas flow rates.

We can implement remote monitoring and control of 40 SI-10FD gas mass flow controllers via DB9 multi-point hubs.

One hub can power 10 MFCs. After connecting four hubs in series to a computer or PLC using communication cables, all 40 MFCs can be configured and read in the software. Wiring is simple and quick. The software can be customized according to customer needs, including adding variation curves and coefficient corrections. The interface is user-friendly and easy to operate.

Technical Support

Buyer’s Guide: 7 Critical Factors for Choosing an Online Gas Detector

What is a Combustible Gas Detector? And 5-Step Selection Guide

5 Essential Factors for Choosing Multi Gas Detectors

7 Critical Gas Detector Calibration Errors to Avoid: An Expert Guide

How Gas Detectors Work: 4 Key Sensor Types

An Expert 7-Point Checklist for Industrial Gas Detection Systems

Buyer’s Guide for Ammonia Gas Monitor

Proven Solutions for the 5 Critical Health Dangers of Ammonia Leaks

Buyer’s Guide: 7 Critical Checks for Selecting a Chlorine Gas Detector

7 Critical Mistakes in Gas Sampling System Design: A Practical Checklist

CO2 Sensor vs. VOC Sensor: What’s the Difference?

Expert Guide: How a Photoionization Detector Works

Guide to Connecting a Thermal Mass Flow Controller to a PLC

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

8 Best Mass Flow Controller Manufacturers

How Does a thermal mass flow controller working principle?

6 Best carbon monoxide detector Test 2025

Top 7 portable combustion analyzer Tested

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

6 Types of Industrial Oxygen Sensors

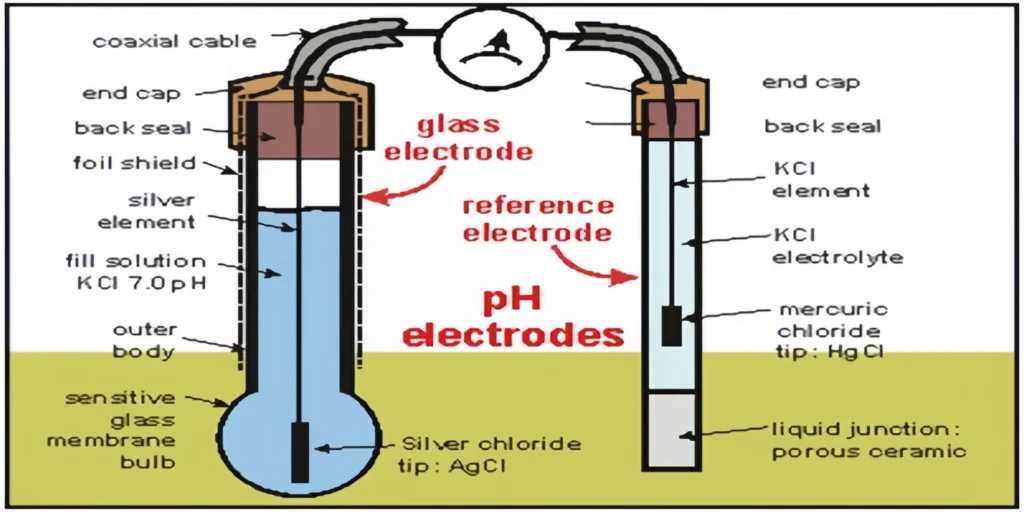

What Is pH in Water? A Complete Guide to Understanding (2026)

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

10 Best carbon monoxide monitor for industrial use 2025

5 Best carbon monoxide detector for garage

Top 8 gas detectors for confined spaces in 2025

Top 6 Mass Flow Controller Manufacturers in the USA

Top 10 Mass Flow Controllers for Gases 2025

7 Best Gas Analyzer Manufacturers in 2025

7 Best 4 Gas Monitors for Industrial Use

Top 8 Portable Gas Detectors for Confined Spaces

8 Best Gas Detector Alarms 2025

Top 5 Heavy-Duty Plastic pH Electrodes for Industrial & Wastewater Applications (2025 Guide)

6 Best Portable Carbon Monoxide Detector for Travel: Stay Safe in 2025

Carbon Monoxide Detector Chirping: Decoding the 5 Most Critical Scenarios

How to Choose the Right pH Sensor: 6 Expert Tips

What is photoionization detector? and use

9 Best Fixed Gas Detector Manufacturers 2026

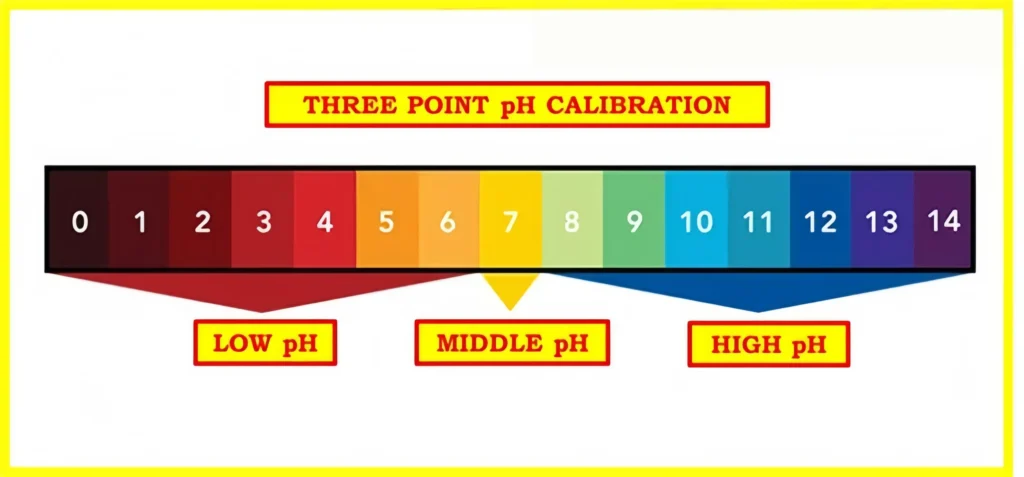

The Essential pH Sensor Calibration Guide: Why Readings Drift and How to Fix

8 Best portable multi gas detector 2026

9 Best handheld gas leak detectors 2026

Top 6 Electrochemical Gas Sensor Manufacturers 2026

7 best carbon monoxide detector on phone 2026

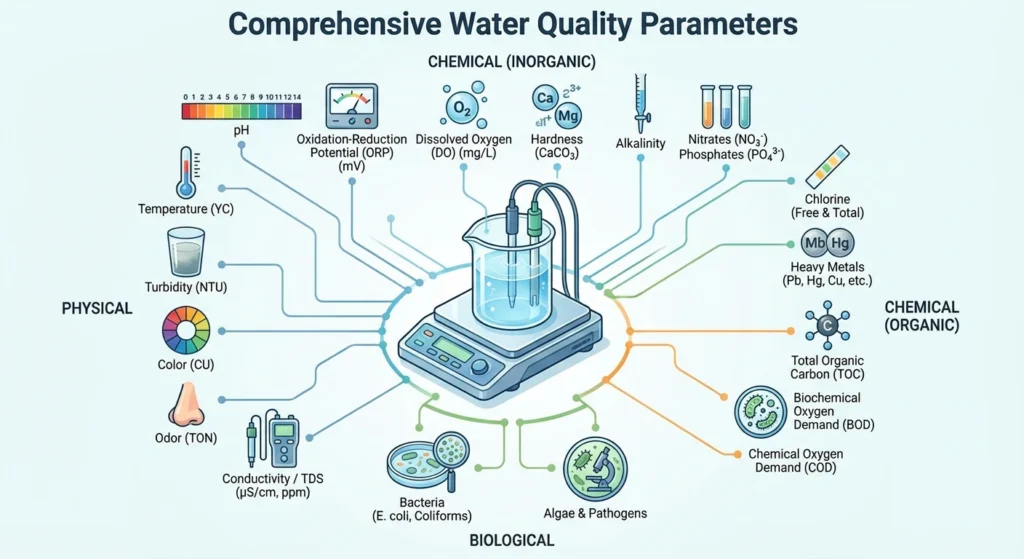

The 3 Layers of Water Quality Parameters: The Practical Guide for Water Pros

6 Best Fixed Gas Detection System 2026: Industrial Safety and Precision

10 Best Gas Line Leak Detectors 2026: Comprehensive Safety Guide

8 Best portable gas monitoring equipments 2026

10 Best Methane Gas Detectors 2026

Safety First: Why is My Carbon Monoxide Alarm Beeping Every 30 Seconds?

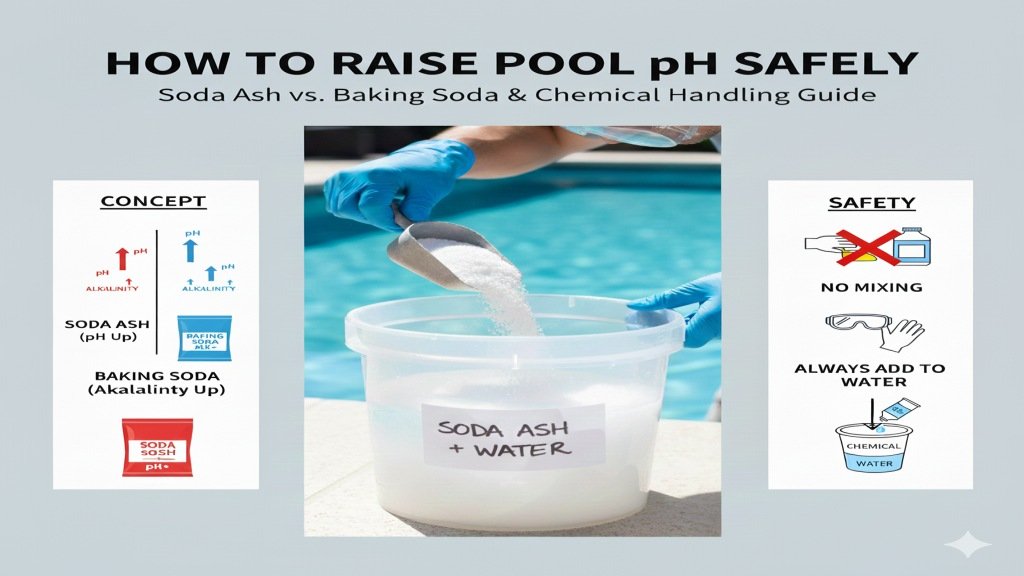

How to Raise pH in Pool: The Chemical Guide & The Automated Solution

The Shocking Truth About the pH of Distilled Water: Why It’s Not 7.0

Carbon Monoxide Levels Chart 2026 Update: Safety Guidelines and PPM Limits

6 Most Reliable Multi Gas Detectors for Industrial Use (2026 Guide)

Industrial Gases List 2026: The Ultimate Guide to Types and Usage

5 Critical Differences: Is Distilled Water the Same as Purified Water?

Mastering Safety: How to Check Gas Level in Confined Space?

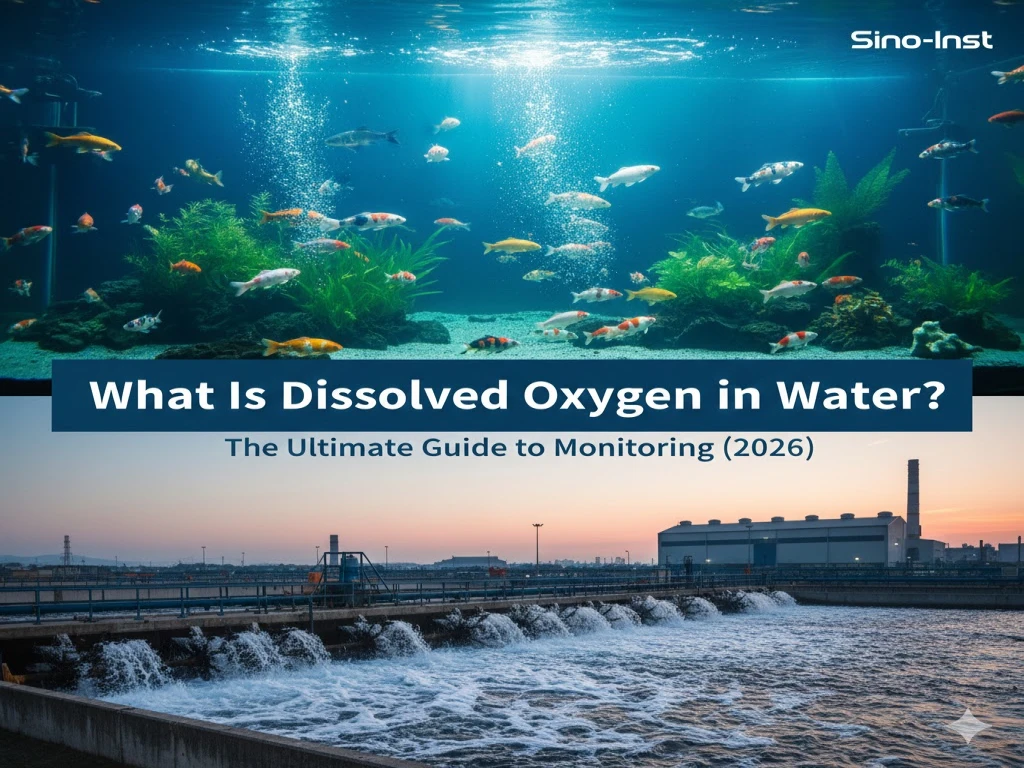

What Is Dissolved Oxygen in Water? The Ultimate Guide to Monitoring(2026)

9 Best Personal Gas Monitoring Devices 2026

Choosing a pH Meter for Water:The Professional Guide to(2026)

How Do I Get My Carbon Monoxide Detector to Stop Chirping? (2026 Guide)

How Do You Test for Helium?

Sino-Inst has developed a flow controller (touchscreen) with an existing display control panel, incorporating advanced industry technology. It allows users to directly set flow rates, read accumulated flow rates, and set quantitative gas supply directly on the Digital Mass Flow Controller/Meter unit. It also enables remote control via connection to peripherals such as computers, touchscreens, and secondary meters.

The gas path connection can be equipped with quick-connect or quick-screw couplings for easy modification, relocation, or portability. When an external DC power supply is inconvenient, an external battery can be used (please specify when ordering) or 220V AC mains power (please specify when ordering).

If you require customized gas flow measurement and control solutions, please feel free to contact our sales engineers!

Request a Quote

Related Products

SI-10FD Digital Mass Flow Controller/Meter |RS232/485-MODBUS

The SI-10FD Digital Mass Flow Controller/Meter is based on thermal mass flow measurement technology, combined with advanced digital signal processing and control algorithms, and supports RS232/485 and MODBUS protocols.

Product In-Stock: InStock

.png)