Anhydrous ammonia (NH₃) is a cornerstone of modern industry, indispensable in agriculture, refrigeration, and chemical manufacturing. Its utility, however, is shadowed by significant health dangers should containment be breached. An ammonia leak presents a multi-faceted threat to human well-being, initiating a cascade of physiological injuries upon exposure.

The primary health dangers of ammonia leaks involve severe damage to the respiratory system, as the gas reacts with moisture to form a corrosive alkaline solution, ammonium hydroxide, leading to cellular destruction from the upper airways to the deep lung tissues. Contact with skin or eyes results in caustic chemical burns, with the potential for permanent vision loss. At high concentrations, ammonia can be absorbed systemically, posing a risk to internal organs. In enclosed areas, an ammonium leak can displace oxygen, creating an asphyxiation hazard.

Mitigating these risks requires a profound understanding of the chemical’s behavior and the implementation of robust safety protocols, centered around reliable, continuous monitoring with a dedicated ammonia gas detector.

The Ubiquitous Nature of Ammonia: Understanding Its Role and Inherent Risks

To grasp the profound health dangers of ammonia leaks, one must first appreciate the chemical’s paradoxical nature. It is both a vital building block for life and industry, yet a potent agent of harm when uncontrolled. Think of a powerful river: when channeled by dams and canals, it irrigates fields and generates power, bringing prosperity. Should the dam break, that same water becomes a destructive flood, erasing everything in its path.

Ammonia, in its industrial context, behaves in a similar fashion. Its containment and proper handling are the dams that separate its utility from its potential for devastation. An ammonium leak represents a breach in these defenses, releasing a hazard that requires immediate respect and a knowledgeable response.

What Exactly is Ammonia (NH₃)? A Chemical Primer

At its most fundamental level, ammonia is a simple compound, a molecule composed of one nitrogen atom bonded to three hydrogen atoms. Its chemical formula, NH₃, is familiar to many. It exists naturally, produced by the decomposition of organic matter, but for industrial purposes, it is synthesized on a massive scale through the Haber-Bosch process. At standard temperature and pressure, ammonia is a colorless gas with a characteristically pungent, suffocating odor. Most people can detect its sharp smell at very low concentrations, often as low as 5 parts per million (ppm), a natural warning sign that should never be ignored.

A defining characteristic of ammonia is its high affinity for water. It dissolves readily in water to form a solution of ammonium hydroxide (NH₄OH). This is a weak base, but it is sufficiently alkaline to be highly corrosive to living tissue. It is precisely this chemical transformation—the reaction of gaseous ammonia with the moisture present in our eyes, skin, and respiratory tract—that is the root cause of the most severe health dangers of ammonia leaks. The gas itself doesn’t burn you; the caustic solution it creates upon contact with your body does.

From Fertilizer to Refrigerant: Common Industrial Applications

The global economy leans heavily on ammonia. Its single largest application, accounting for over 80% of production, is as an agricultural fertilizer. The nitrogen it provides is essential for plant growth, making ammonia a linchpin of modern food production. Without synthetic ammonia, global crop yields would plummet, unable to support the current population.

Beyond the farm, ammonia is a workhorse in refrigeration. Large-scale industrial refrigeration systems, such as those found in food processing plants, cold storage warehouses, and beverage production facilities, rely on ammonia’s excellent thermodynamic properties. It is an efficient and cost-effective refrigerant, though its toxicity makes leaks a constant concern in these environments. An ammonium leak in a cold storage facility is a particularly dangerous scenario.

The chemical industry uses ammonia as a precursor for producing a vast array of other materials, including plastics, textiles like nylon, explosives, and pharmaceuticals. It is also used in water purification and as a cleaning agent in various commercial products, albeit in much more dilute forms. This widespread use means that facilities handling ammonia are present not just in isolated industrial parks but often near populated areas, making public safety a consideration alongside worker protection. An ammonia leak dangerous to workers can also pose a risk to the surrounding community.

The Tipping Point: When a Useful Chemical Becomes a Hazard

The transition from a useful chemical to a severe hazard occurs at the moment of an uncontrolled release—an ammonia leak. This can happen for numerous reasons: equipment failure, such as a corroded pipe or a faulty valve; procedural error, like improper connection or disconnection of a transfer hose; or external damage, such as a forklift collision with a storage tank.

Once released, gaseous ammonia, which is lighter than air, will typically rise and dissipate in open areas. However, in enclosed or poorly ventilated spaces, it can accumulate to dangerous concentrations. The anhydrous ammonia stored as a liquid under pressure presents another danger. If a vessel is breached, the liquid rapidly boils and expands into a large cloud of vapor, which is initially cold and denser than air. This cloud can hug the ground, spreading the danger far from the initial leak point before it eventually warms, rises, and disperses.

Understanding these behaviors is vital for predicting how an ammonium gas leak will spread and who is at risk. The health dangers of ammonia leaks are directly tied to the concentration of the gas in the air and the duration of exposure.

Danger 1: Severe Respiratory System Damage

The human respiratory system is an intricate and delicate structure, designed for the efficient exchange of gases but profoundly vulnerable to chemical assault. When an ammonia leak occurs, the respiratory tract is the primary and most immediate battleground. The experience of inhaling ammonia is not subtle; it is an immediate, violent affront to the senses and tissues. The severity of the damage is a direct function of the concentration of the gas and the length of time a person is exposed. The health dangers of ammonia leaks are perhaps most acutely and frequently manifested in the lungs.

The Immediate Onslaught: How Ammonia Attacks the Lungs

Imagine the moist, sensitive surfaces of your nose, throat, and lungs. These tissues are perpetually bathed in a thin layer of fluid. When ammonia gas (NH₃) is inhaled, it instantly dissolves into this fluid layer. This chemical reaction creates ammonium hydroxide (NH₄OH), a strong alkaline substance. The effect is analogous to spilling a caustic cleaning agent directly into your airways.

The ammonium hydroxide begins to destroy cells on contact through a process called liquefactive necrosis. It saponifies fats in the cell membranes, basically turning them into soap, and denaturates cellular proteins, causing the cells to rupture and die. This process triggers an intense inflammatory response. The body rushes fluid and immune cells to the site of injury, attempting to neutralize the chemical and repair the damage.

This very response, however, contributes to the life-threatening conditions that follow. The initial sensation is a burning pain in the nose and throat, followed by uncontrollable coughing and gasping as the body desperately tries to expel the corrosive agent. An ammonium gas leak poses an immediate threat to anyone in the vicinity without respiratory protection.

From Irritation to Edema: A Spectrum of Respiratory Injuries

The extent of respiratory injury exists on a grim spectrum, dictated by the concentration of ammonia in the air.

| Concentration (ppm) | Time | Physiological Effects and Symptoms |

| 5-50 ppm | 8 hours | Mild irritation to eyes, nose, and throat. The odor is easily detectable. Considered the upper limit for safe long-term exposure. |

| 100-200 ppm | Minutes to Hours | Increasing irritation, coughing, and discomfort. Prolonged exposure can lead to more significant inflammation. |

| 300-500 ppm | < 30 minutes | Immediately Dangerous to Life or Health (IDLH). Severe irritation, corrosive action begins. Risk of bronchospasm. Evacuation is urgent. |

| 700-1,700 ppm | Minutes | Severe coughing, laryngospasm (vocal cords seize). Even brief exposure can cause significant damage and potential for pulmonary edema. |

| 2,500-5,000+ ppm | Seconds to Minutes | Rapidly fatal. Massive pulmonary edema, airway destruction, and asphyxiation due to fluid buildup and tissue damage. |

At lower concentrations, the result might be tracheitis (inflammation of the trachea) or bronchitis (inflammation of the bronchi). Symptoms include a sore throat, chest pain, and a persistent cough. As concentrations increase, the damage deepens. The body’s inflammatory response can cause the airway tissues to swell, a condition known as laryngeal edema or bronchospasm, which can constrict or completely block the passage of air.

The most feared acute consequence is non-cardiogenic pulmonary edema. The massive cellular injury in the alveoli—the tiny air sacs where oxygen exchange occurs—makes the capillaries leaky. Plasma fluid floods into the alveoli, filling the lungs with fluid and making it impossible to breathe. The victim is, in a very real sense, drowning on the inside. This is a severe medical emergency requiring immediate hospitalization. The health dangers of ammonia leaks escalate rapidly from discomfort to a life-threatening crisis.

Long-Term Consequences: Chronic Conditions from Acute Exposure

Surviving a severe ammonia inhalation injury does not always mean a return to normal. The healing process itself can leave behind permanent scars. The body may repair the damaged airways with fibrous tissue, leading to a narrowing of the bronchioles, a condition known as bronchiolitis obliterans. This can result in a permanent decrease in lung function, causing chronic shortness of breath, wheezing, and a reduced capacity for physical exertion.

Some individuals develop Reactive Airways Dysfunction Syndrome (RADS), a form of asthma that begins after a single, high-concentration exposure to an irritant gas like ammonia. Unlike typical asthma, RADS is not an allergic response but a direct result of chemical injury to the airways, leading to long-term bronchial hyperresponsiveness. The lingering effects of an ammonium leak can impact a person’s quality of life and ability to work for years, serving as a constant reminder of the exposure. This is why preventing exposure in the first place, through robust engineering controls and a reliable ammonia leak detector, is not just a matter of immediate safety but of long-term health.

Danger 2: Caustic Burns to Skin and Eyes

While the respiratory system is often the first and most severely affected, the health dangers of ammonia leaks extend to every part of the body that makes contact with the gas. The skin and eyes, our primary interfaces with the world, are exceptionally vulnerable. The mechanism of injury is the same: the reaction of ammonia gas with surface moisture to form corrosive ammonium hydroxide. However, the consequences for these specific organs are unique and devastating. An ammonia leak dangerous to the lungs is equally dangerous to the eyes and skin.

The Mechanism of Injury: How Ammonia Corrodes Living Tissue

The human skin provides a formidable barrier, but it is not impervious. When exposed to high concentrations of ammonia gas, the moisture from sweat and humidity on the skin’s surface is enough to initiate the corrosive reaction. The ammonium hydroxide formed begins to break down the skin’s protective layers. As previously mentioned, it causes liquefactive necrosis, a type of cell death where the tissue turns into a viscous liquid mass. This process allows the chemical to penetrate deeper and deeper into the underlying tissues, causing more extensive damage than coagulative necrosis, which tends to be self-limiting.

For liquid anhydrous ammonia, the danger is twofold. First, it is stored at extremely cold temperatures (around -33°C or -28°F). Contact with the liquid causes severe frostbite, freezing tissue almost instantly. Second, as the liquid rapidly warms and evaporates on the skin, it draws a massive amount of heat from the body, compounding the freezing injury. This is immediately followed by the caustic burn from the formation of ammonium hydroxide as the ammonia reacts with tissue moisture. The combination of a cryogenic and a chemical burn is exceptionally destructive.

| Control Type | Description | Examples |

| Engineering Controls | Modifying the work environment to isolate people from the hazard. This is the most effective level of control. | – Process containment (using closed-loop systems). – General and local exhaust ventilation. – Physical barriers and blast walls. – Automated shut-off valves linked to an ammonia gas detector. |

| Administrative Controls | Changing the way people work to limit exposure. These rely on human behavior and are less reliable than engineering controls. | – Comprehensive worker training programs. – Standard Operating Procedures (SOPs) for handling ammonia. – Job rotation to limit individual exposure times. – Clear signage and area demarcation. – Regular equipment maintenance schedules. |

| Personal Protective Equipment (PPE) | Equipment worn by the worker to protect against the hazard. This is the last line of defense and depends on proper selection, fit, and use. | – Gas-tight chemical splash goggles and face shield. – Ammonia-rated respirator with appropriate cartridges. – Non-porous, chemical-resistant gloves and boots. – Level A or B encapsulated chemical-resistant suit for emergency response. |

Ocular Emergencies: The Irreversible Threat to Vision

The eye is arguably the organ most susceptible to permanent damage from an ammonia leak. The cornea, the clear front surface of the eye, is kept moist by the tear film. When ammonia gas reaches the eye, it dissolves instantly in this film, creating ammonium hydroxide directly on the ocular surface. The cornea has no blood supply to help buffer or carry away the chemical; the damage is immediate and concentrated.

The alkaline nature of ammonium hydroxide allows for rapid penetration through the layers of the cornea and into the anterior chamber of the eye—the fluid-filled space behind the cornea. It can raise the internal pH of the eye, damaging the iris, the lens, and the trabecular meshwork which regulates internal eye pressure. This can lead to glaucoma, cataracts, and complete destruction of the corneal tissue, resulting in opacification and blindness. The pain is excruciating, described as a severe, unrelenting burning.

Because the alkali penetrates so deeply, damage can continue for hours or even days after the initial exposure, even with irrigation. The potential for irreversible vision loss makes any exposure of the eyes to ammonia a dire medical emergency. The health dangers of ammonia leaks are starkly illustrated by the fragility of human sight.

Dermal Injuries: From Redness to Deep Tissue Necrosis

Skin exposure to ammonia gas or liquid results in injuries that resemble thermal burns and are classified similarly.

A first-degree burn involves the superficial layer of the skin (epidermis). It is characterized by redness, pain, and mild swelling, similar to a sunburn. This typically results from exposure to lower concentrations of ammonia gas for a short period.

A second-degree burn involves damage to the epidermis and the dermis below. These burns are intensely painful and result in the formation of blisters. The skin will be red, swollen, and may appear weepy. This can occur from higher gas concentrations or brief contact with liquid ammonia.

A third-degree burn is a full-thickness injury, destroying the epidermis and dermis and extending into the subcutaneous tissue. The burn site may appear white, leathery, or charred. A deceptive feature of third-degree burns is that they are often painless because the nerve endings in the skin have been destroyed. These are the most severe types of chemical burns, often caused by prolonged contact with high gas concentrations or significant liquid ammonia exposure. They require extensive medical intervention, inclu

Danger 3: Systemic Toxicity and Internal Organ Damage

While the immediate, corrosive health dangers of ammonia leaks are concentrated at the points of contact—the lungs, skin, and eyes—very high concentrations of the gas can lead to systemic poisoning. This occurs when the body’s local defenses are overwhelmed, and a significant amount of ammonia is absorbed into the bloodstream. Once in circulation, it can exert toxic effects on vital organ systems, most notably the central nervous system. This dimension of ammonia’s danger is less common than contact burns but is critically important to understand for worst-case scenarios.

Beyond the Point of Contact: How Ammonia Enters the Bloodstream

The primary route for systemic absorption is through the lungs. During a high-concentration inhalation event, the sheer amount of ammonia entering the alveoli can exceed the capacity of the local tissues to contain it. The vast surface area and rich blood supply of the lungs, designed for efficient gas exchange, unfortunately also facilitate the absorption of toxic gases into the circulation. A smaller amount can also be absorbed through severely damaged skin.

Once in the blood, the body has a natural mechanism for detoxification. The liver plays a central role in this, converting ammonia into urea through the urea cycle. Urea is a much less toxic compound that can then be safely excreted by the kidneys. However, a massive influx of ammonia from an acute exposure can saturate this metabolic pathway. The liver simply cannot process the ammonia fast enough, and its concentration in the blood begins to rise, a condition known as hyperammonemia. It is this elevated level of ammonia in the blood that leads to systemic toxic effects.

The Impact on the Nervous System and Other Vital Organs

The brain is particularly vulnerable to the effects of hyperammonemia. Ammonia readily crosses the blood-brain barrier. Inside the brain, it disrupts cerebral energy metabolism and neurotransmitter systems. It can lead to an increase in the concentration of glutamate, an excitatory neurotransmitter, which can cause excitotoxicity and neuronal cell death. Ammonia also leads to swelling of astrocytes, a type of brain cell, which contributes to cerebral edema—swelling of the brain.

The clinical manifestations of this neurotoxicity range from mild to severe. Initial symptoms might include headache, nausea, vomiting, and confusion. As blood ammonia levels rise, the symptoms can progress to ataxia (loss of coordination), seizures, combativeness, and eventually, coma and death. The effects on the central nervous system are a stark reminder that an ammonia leak dangerous to the lungs can also be a direct poison to the brain.

While the brain is the primary target, other organs can be affected. The liver itself can be damaged by the metabolic stress of trying to detoxify the massive ammonia load. The kidneys can also be impacted, both from the stress of excreting the byproducts and from potential systemic effects like shock.

Understanding Concentration Thresholds for Systemic Effects

Systemic toxicity is generally associated with exposure to very high concentrations of ammonia, typically well above 1,000 ppm. At these levels, the immediate corrosive effects on the respiratory system are so severe that they are often the primary cause of death. A person exposed to 2,500 ppm of ammonia may succumb to pulmonary edema before the full effects of systemic poisoning can manifest.

However, in scenarios where a person is briefly exposed to an extremely high concentration and then immediately rescued, they may survive the initial lung injury only to face the subsequent challenges of hyperammonemia. These situations are rare but highlight the multi-systemic nature of the health dangers of ammonia leaks. The focus of safety systems, including the placement of an ammonia leak detector, should be on preventing any exposure that approaches these dangerous levels. The goal is not just to prevent irritation but to avert catastrophic corrosive injury and systemic poisoning. The effective use of an ammonia gas detector is a fundamental part of this preventative strategy.

Danger 4: Asphyxiation in Confined Spaces

In addition to its corrosive and toxic properties, ammonia poses another, more subtle danger: asphyxiation. This risk is particularly acute in confined or poorly ventilated spaces, where a leaking gas can displace the oxygen necessary for life. An asphyxiation hazard from an ammonium leak is not about poisoning in the traditional sense; it is about the simple, brutal removal of breathable air. This makes it an especially insidious threat in many industrial settings.

The Science of Oxygen Displacement

The air we breathe is a mixture of gases, composed of approximately 20.9% oxygen, 78% nitrogen, and small amounts of other gases. Human life depends on this steady concentration of oxygen. Our bodies cannot store oxygen; we need a continuous supply with every breath to power our cellular metabolism. If the oxygen concentration in the air we breathe drops below a certain level, our bodily functions begin to fail.

When an ammonia leak occurs in an enclosed area like a refrigeration machinery room, a storage tank, or a utility tunnel, the ammonia gas fills the space. Because it is a gas, it occupies volume, and in doing so, it pushes out or displaces the normal air, including the oxygen. A large leak can rapidly reduce the oxygen concentration from the life-sustaining 20.9% to levels that are immediately dangerous. An individual entering such an environment might not immediately notice the lack of oxygen. There is no dramatic choking sensation; the onset can be deceptively quiet.

Recognizing High-Risk Environments for Asphyxiation

A “confined space” is typically defined as an area large enough for an employee to enter and perform work, but has limited or restricted means for entry or exit, and is not designed for continuous employee occupancy. These are the primary locations where an ammonium gas leak can lead to asphyxiation.

Common examples in industries that use ammonia include:

- Refrigeration Machinery Rooms: These are often enclosed to contain noise and equipment, but this also contains any potential leaks.

- Storage Tanks and Vessels: Workers performing maintenance or inspection inside tanks are at extreme risk.

- Sumps, Pits, and Trenches: Ammonia gas is initially cold and dense upon release from a liquid leak, causing it to sink and accumulate in low-lying areas.

- Walk-in Coolers and Freezers: Large industrial freezers can become deadly traps if the refrigeration coils develop a significant ammonia leak.

The health dangers of ammonia leaks in these spaces are magnified because escape can be difficult. A worker might become disoriented from lack of oxygen before they can find the exit.

The Silent Killer: Why Asphyxiation is a Deceptive Danger

The human body’s primary trigger to breathe is the buildup of carbon dioxide (CO₂) in the blood, not the lack of oxygen (O₂). In an oxygen-deficient atmosphere caused by displacement with an inert gas or a substance like ammonia, a person can continue to breathe normally, exhaling CO₂. Without the high-CO₂ signal, the brain does not register an emergency.

This leads to a terrifying sequence of events. At an oxygen level of around 15-19%, a person may experience impaired coordination and judgment. Below 12-15%, respiration increases, and they may have a poor ability to perform tasks. Below 10-12%, judgment is further impaired, and lips may turn blue. At 8-10%, mental failure, fainting, and unconsciousness occur. Below 6% oxygen, a person will experience convulsions, respiratory arrest, and cardiac arrest within minutes.

A worker can enter an oxygen-deficient space, feel a little light-headed, and then lose consciousness without any significant struggle. They simply fall asleep and never wake up. While ammonia’s pungent odor is a warning sign, at very high concentrations from a rapid leak, the asphyxiation can happen so quickly that the odor becomes a secondary factor. This is why entry into any confined space where an ammonium gas leak is possible must be governed by strict protocols, including atmospheric testing with a multi-gas meter that measures oxygen levels in addition to having a dedicated ammonia leak detector.

Danger 5: Fire and Explosion Hazards

While ammonia is not flammable in the same way as natural gas or gasoline, it is a mistake to consider it non-combustible. Under the right conditions, an ammonia leak can lead to a fire or, more catastrophically, an explosion. This aspect of the health dangers of ammonia leaks is often underestimated, leading to incidents that could have been prevented. Understanding the specific conditions under which ammonia becomes a fire hazard is essential for comprehensive safety planning in any facility that handles it.

Understanding Ammonia’s Flammability Range

For any substance to burn, three things are needed: fuel (in this case, ammonia), an oxidizer (typically oxygen from the air), and an ignition source. The concentration of the fuel in the air is also critical. If there is too little fuel (a “lean” mixture), it won’t ignite. If there is too much fuel and not enough oxygen (a “rich” mixture), it also won’t ignite. The range of concentrations between these two points is called the flammability or explosive range.

For ammonia, the flammability range is approximately 15% to 28% by volume in air. This range is relatively narrow compared to other flammable gases like hydrogen (4% to 75%). Additionally, ammonia has a relatively high autoignition temperature of 651°C (1,204°F), which is the temperature at which it will ignite without a spark or flame. These properties make it more difficult to ignite than many other common fuels. However, “difficult” does not mean “impossible,” and the consequences of an ignition event within this range can be devastating. An ammonia leak dangerous for its toxicity can become explosive under these conditions.

Common Ignition Sources in Industrial Settings

In an industrial environment where a large ammonia leak has occurred, creating a concentration within the flammable range, there are numerous potential ignition sources that can trigger a fire or explosion. These include:

- Open Flames: Welding torches, cutting equipment, and pilot lights are obvious sources.

- Sparks: Electrical sparks from non-explosion-proof motors, switches, relays, or even static electricity discharge can provide enough energy to ignite an ammonia-air mixture.

- Hot Surfaces: The high autoignition temperature means that a hot surface, such as an overheated motor, a piece of uninsulated steam piping, or a diesel engine manifold, can serve as the ignition source.

- Frictional Heat: Grinding or other mechanical operations that generate significant friction can also create a point of ignition.

The presence of oil or other contaminants mixed with the ammonia can sometimes widen the flammability range or lower the ignition energy required, increasing the risk. Because of this, good housekeeping and preventing the accumulation of combustible materials in areas with ammonia systems are important safety measures.

Case Studies: Learning from Past Explosive Incidents

History provides sober lessons on the explosive power of ammonia. One notable incident occurred in 2013 at a poultry processing plant in China, resulting in over 120 fatalities. An ammonia leak from the refrigeration system ignited and exploded, causing a massive fire. The investigation pointed to a combination of a large, uncontained leak creating a flammable atmosphere and the presence of ignition sources within the facility. The exits were also reportedly blocked, trapping workers inside.

Such incidents underscore that while the flamability of ammonia is conditional, its destructive potential is absolute. A pressure vessel containing liquid ammonia that is exposed to an external fire can also lead to a BLEVE (Boiling Liquid Expanding Vapor Explosion). The fire heats the vessel, increasing the internal pressure until the tank ruptures catastrophically, releasing its entire contents in a massive, and often ignited, fireball.

Managing the fire and explosion hazard requires a multi-layered approach. This includes using explosion-proof electrical equipment in areas where a leak could occur, controlling all ignition sources through hot work permit systems, and, most importantly, preventing the formation of a flammable atmosphere in the first place through robust leak prevention and detection. A reliable ammonium gas leak detection system is a critical tool to alert personnel long before concentrations reach the lower explosive limit (LEL) of 15%.

Proactive Defense: The Imperative of Ammonia Gas Detection

Confronted with the severe and multifaceted health dangers of ammonia leaks, a reactive stance is indefensible. Waiting for the pungent odor of ammonia to signal a problem is waiting too long; by the time it is easily smelled, concentrations may already be at a level that causes irritation and harm. A proactive defense, centered on the principle of early warning, is the only responsible approach. This is where the technology of gas detection becomes not just a tool, but a guardian. An ammonia gas detector serves as an unblinking sentinel, constantly monitoring the air for the first sign of a breach.

The Philosophy of Early Warning Systems

The core philosophy behind gas detection is simple: identify the hazard before it can cause harm. A well-designed gas detection system is intended to provide alerts at multiple, escalating levels.

- Low-Level Alert: This first alarm is typically set at a low concentration, for example, 25 ppm. It is not a signal of immediate danger but an indication of a small, developing leak. It alerts personnel to investigate the source and take corrective action before the situation worsens, preventing a minor issue from becoming a major incident.

- High-Level Alert: This second alarm is set at a higher concentration, perhaps 50 ppm or more. This indicates a more serious leak that requires a more urgent response. It may trigger automated actions, such as increasing ventilation rates or activating warning beacons. It signals to personnel that they should prepare for possible evacuation or don appropriate PPE.

- Emergency Alert (IDLH): A third, critical alarm level is often set at or below the Immediately Dangerous to Life or Health (IDLH) concentration of 300 ppm. This alarm signals a life-threatening situation. It should trigger immediate evacuation of all non-essential personnel and initiate the full emergency response plan.

This tiered approach allows for a measured response, preventing both complacency and unnecessary panic, while ensuring that catastrophic failures are met with the highest level of urgency.

A Comparative Look: Fixed vs. Portable Ammonia Gas Detectors

Ammonia detection is not a one-size-fits-all solution. The choice between fixed and portable detectors depends on the application and the safety objective.

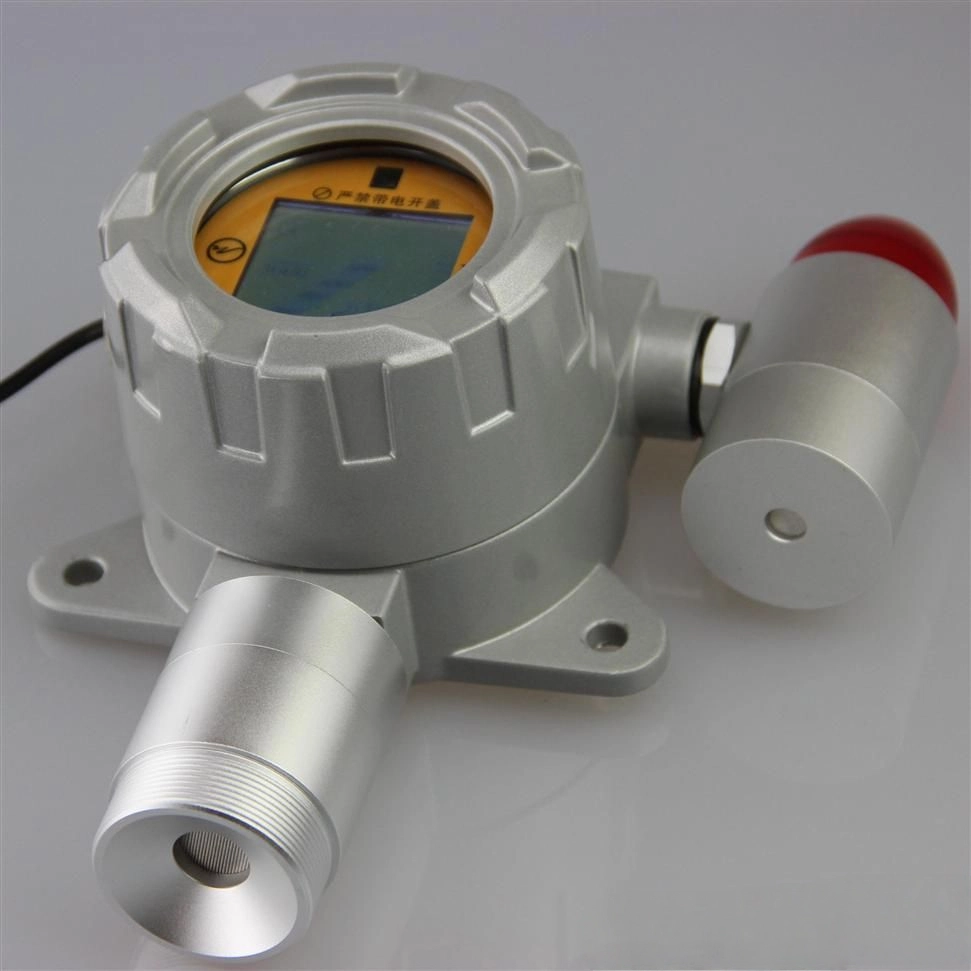

Fixed Ammonia Gas Detectors are permanently installed in a specific location to provide continuous, 24/7 monitoring of a particular area. They are the primary tool for monitoring large spaces like refrigeration machinery rooms, chemical storage areas, and along process lines.

- Advantages: Continuous, unattended operation. Can be integrated with other plant control systems to automatically trigger alarms, ventilation, or shutdowns. Provides protection for the area even when it is unoccupied.

- Disadvantages: Only monitor the specific point where they are installed. A leak occurring far from a sensor may not be detected quickly. Requires careful planning for optimal placement.

Portable Ammonia Gas Detectors are personal safety devices carried by individual workers, or handheld units used for leak pinpointing and confined space entry.

- Advantages: Provides protection for the worker wherever they go. Can be used to find the exact source of a leak that a fixed detector has identified. Essential for verifying that a confined space is safe for entry.

- Disadvantages: Only protects the individual carrying it. Relies on the worker to use it correctly and respond to its alarms. Battery-dependent. Does not provide area-wide protection.

A comprehensive safety program often employs both. Fixed detectors provide the baseline area monitoring, while portable detectors protect workers as they move through the facility and perform specific high-risk tasks.

Sensor Technologies Explained: Electrochemical, MOS, and Infrared

The “heart” of any ammonia leak detector is its sensor. Different technologies are used, each with its own strengths and weaknesses.

- Electrochemical (EC) Sensors: These are the most common type for toxic gas detection, including ammonia. The gas diffuses into the sensor and reacts at an electrode, generating a small electrical current that is directly proportional to the gas concentration.

- Pros: High sensitivity to low ppm concentrations, relatively low power consumption, good selectivity.

- Cons: Limited lifespan (typically 1-3 years), can be affected by extreme temperatures and humidity, susceptible to cross-interference from other gases. They are a consumable item that requires periodic replacement.

- Metal Oxide Semiconductor (MOS) Sensors: These sensors use a heated metal oxide film. When ammonia gas comes into contact with the film, it changes the film’s electrical resistance. This change is measured to determine the gas concentration.

- Pros: Long lifespan (5+ years), robust, can detect a wide range of gases.

- Cons: High power consumption due to the heater, can have a slower response and recovery time, often less selective than EC sensors, and can be affected by humidity.

- Infrared (IR) Sensors: These sensors work by passing a beam of infrared light through the gas sample. Ammonia molecules absorb light at a specific wavelength. The sensor measures how much light is absorbed to calculate the concentration.

- Pros: Very long lifespan, fail-safe operation (a loss of signal indicates a fault), immune to “poisoning,” fast response.

- Cons: Higher initial cost, may not be as sensitive to very low ppm concentrations as EC sensors. They are excellent for detecting leaks before they reach the LEL.

The choice of sensor technology is a critical decision that depends on the specific needs of the application, including the required detection range, environmental conditions, and maintenance budget.

Selecting the Right Ammonia Gas Detector for Your Application

Choosing the correct ammonia gas detector is a process of careful consideration. One must evaluate the specific environment where the detector will be placed. Is it a clean, climate-controlled room or a harsh outdoor environment with fluctuating temperatures and humidity? One must also define the primary purpose. Is the goal to detect small, nuisance leaks early (requiring a high-sensitivity EC sensor) or to monitor for large, potentially explosive leaks (where a robust IR sensor might be better)?

Consulting with experts in gas detection is invaluable. They can help conduct a site survey to identify the most likely leak points and the best locations for sensor placement. Factors like air currents, the density of the gas, and the physical layout of the facility must all be taken into account. Investing in the right detection technology is a direct investment in the health and safety of every person in the facility. It is the most tangible expression of a commitment to preventing the health dangers of ammonia leaks.

Establishing a Comprehensive Ammonia Safety Protocol

Technology alone, even the most advanced ammonia gas detector, is not a complete safety solution. It is a vital component of a much larger, integrated safety system. A truly robust defense against the health dangers of ammonia leaks is built upon a hierarchy of controls, a foundational principle of industrial hygiene. This hierarchy prioritizes the most effective and reliable methods of risk reduction. It moves from engineering solutions that remove the hazard, to administrative rules that change how people work, and finally, to personal protective equipment (PPE) as the last resort.

Engineering Controls: Ventilation and Process Isolation

The most effective way to prevent exposure to an ammonia leak is to control it at the source. This is the domain of engineering controls.

- Process Isolation and Containment: The first preference is always to keep the ammonia inside the pipes and vessels. This involves using high-quality, corrosion-resistant materials for construction, implementing a rigorous mechanical integrity program with regular inspections (e.g., ultrasonic thickness testing), and using all-welded piping where possible to minimize potential leak points like flanges and gaskets.

- Ventilation: This is perhaps the most critical engineering control for managing an ammonium gas leak.

- General Exhaust Ventilation: In areas like refrigeration machinery rooms, powerful ventilation systems are designed to continuously exchange the air, preventing any small leaks from accumulating to dangerous concentrations.

- Local Exhaust Ventilation (LEV): At points where ammonia might be released intentionally, such as sampling points or charging stations, an LEV system can capture the vapors at the point of generation before they enter the worker’s breathing zone.

- Emergency Ventilation: Many systems are designed to switch to a much higher-flow emergency mode when an ammonia gas detector signals a leak, rapidly purging the contaminated air from the space.

Administrative Controls: Training, Signage, and Emergency Procedures

When engineering controls cannot eliminate the risk entirely, we rely on administrative controls—the rules and procedures that govern how work is done safely.

- Training: Every worker who operates in an area with ammonia must receive comprehensive training. This must cover not only the health dangers of ammonia leaks but also the proper operating procedures, the location and use of safety equipment like emergency showers and eyewash stations, the meaning of the gas detector alarms, and the specific steps of the emergency evacuation plan. Training is not a one-time event; it requires regular refreshers.

- Standard Operating Procedures (SOPs): Clear, written procedures must be in place for all tasks involving ammonia, from routine operations to non-routine maintenance. These SOPs reduce the chance of human error, a common cause of industrial accidents.

- Signage and Labeling: All areas containing ammonia, and all pipes carrying it, must be clearly labeled. Warning signs indicating the presence of ammonia, the required PPE, and emergency contact information should be prominently displayed.

- Emergency Response Plan: A detailed, site-specific plan must be developed and practiced. Who do you call? Where are the evacuation routes and muster points? Who is authorized to attempt a shutdown? How are personnel accounted for? Regular drills are essential to ensure that in the chaos of a real emergency, everyone knows exactly what to do.

Personal Protective Equipment (PPE): The Last Line of Defense

PPE is the final barrier between a worker and a chemical hazard. It is used when engineering and administrative controls are not feasible or are insufficient to control the exposure. It is crucial to remember that PPE does not eliminate the hazard; it only protects the wearer, and only if it is selected, worn, and maintained correctly.

- Respiratory Protection: This can range from an air-purifying respirator with ammonia-specific cartridges for low-level exposures to a supplied-air respirator (SAR) or self-contained breathing apparatus (SCBA) for high-concentration or emergency response scenarios. Fit testing is mandatory to ensure a proper seal.

- Eye and Face Protection: Chemical splash goggles are the minimum requirement. A face shield should be worn over the goggles for added protection against splashes.

- Skin Protection: This includes chemical-resistant gloves (e.g., butyl rubber or neoprene), boots, and a chemical-resistant suit or apron. The level of protection must be matched to the potential for exposure, ranging from simple splash protection to a fully encapsulating Level A suit for emergency responders entering a major leak.

The Role of Continuous Monitoring with an Ammonium Gas Leak Detection System

A continuous monitoring system, built around a network of strategically placed fixed gas detectors, is the nervous system of a comprehensive safety protocol. It is the technology that enables the other controls to function effectively. An ammonium gas leak detection system provides the trigger for the emergency ventilation to activate. It sounds the alarms that tell workers to evacuate or don their PPE. Its data logs provide valuable information for incident investigation and can help identify recurring small leaks that indicate a need for maintenance. Without reliable detection, a facility is operating blind, unaware of a developing crisis until it is too late.

FAQ

Related Products

Reflecting on the evidence presented, the narrative of ammonia in our industrial world is one of profound duality. It is a substance of immense benefit, yet it carries an inherent and serious potential for harm. The health dangers of ammonia leaks are not abstract possibilities; they are concrete, scientifically understood consequences of uncontrolled releases. From the violent, corrosive assault on the respiratory tract and eyes to the silent threat of asphyxiation in confined spaces, ammonia demands our utmost respect and vigilance. Its capacity to cause deep chemical burns, systemic poisoning, and even explosions under specific conditions completes a formidable risk profile.

However, a fatalistic view is not the appropriate response. These dangers, while severe, are manageable. The key lies in a shift from a reactive to a proactive safety culture. This involves a deep commitment to the hierarchy of controls, prioritizing robust engineering solutions like ventilation and process integrity. It requires diligent administrative oversight through comprehensive training and meticulously planned emergency procedures. It mandates the correct use of personal protective equipment as the final, essential shield for the worker.

At the very heart of this modern safety paradigm is the unblinking eye of technology: the ammonia gas detector. These instruments are the sentinels that stand guard, providing the critical early warning that transforms a potential catastrophe into a manageable incident. By understanding the nature of ammonia, recognizing its specific dangers, and implementing a multi-layered, detection-centered safety protocol, we can continue to harness the immense benefits of this vital chemical while upholding our fundamental ethical obligation to protect the health and lives of those who work with it. The path to safety is paved with knowledge, preparation, and the right technological tools.

More Resources

-

Is It Safe to Drink Purified Water? Practical Guide to Making a Healthy Choice.

Is it safe to drink purified water? “Is the most crucial question for health conscious consumers when choosing bottled water or home water…

-

5 Kinds of Detector Detects Gas Leaks: Expert Selection Guide

In industrial safety, the margin for error is non-existent. Whether managing a petrochemical refinery, an agricultural greenhouse, or a manufacturing plant, the ability…

-

Total Chlorine vs Free Chlorine: The Complete Industrial Monitoring Guide (2026)

Introduction:Why the Chlorine”Guess”Costs You Money? In water treatment,precision isn’t just a goal;it’s a safety requirement.Many operators ask:”Is total chlorine vs free chlorine same?“The…

-

5 Expert Tips to Put an Explosive Gas Detector for Maximum Safety

Safety is not a variable; it is a constant requirement in industrial process control. When dealing with combustible gases, the difference between a…

-

9 Best VOC Detectors for 3D Printing Safety (2026 Guide)

As 3D printing technology moves from industrial factories to home workshops and small businesses, air quality safety has become a paramount concern. Whether…

-

What Does Muriatic Acid Do for a Pool?(2026)

Maintaining a crystal-clear swimming pool is a balancing act of chemistry. Among all the chemicals in a pool professional’s kit, muriatic acid is…

.png)