The pervasive use of ammonia (NH₃) across industries such as refrigeration, agriculture, and chemical manufacturing necessitates robust safety protocols, with gas detection being a primary component.

We will explore the key considerations for selecting, implementing, and maintaining high-efficiency ammonia detectors. We will analyze various ammonia sensor technologies—including electrochemical sensors, metal-oxide-semiconductor sensors, and infrared sensors—and compare their operating principles, performance characteristics, and limitations.

Our goal is to equip safety managers, engineers, and procurement experts with the nuanced understanding needed to make informed decisions, thereby improving workplace safety and ensuring regulatory compliance through the proper deployment of ammonia detection systems.

Understanding Ammonia (NH₃): The Invisible Hazard in Plain Sight

Before one can begin the methodical process of selecting an instrument for detection, a foundational understanding of the substance itself is paramount. Ammonia is not merely a chemical compound; it is a substance with a dual nature, embodying both immense utility and significant danger. Its presence in our industrial world is so widespread that we often forget the vigilance its handling demands. Let us begin by exploring this duality, to better appreciate the gravity of the task of monitoring it.

The Chemical Nature of Ammonia: A Double-Edged Sword

Ammonia, with the chemical formula NH₃, is a compound of nitrogen and hydrogen. At standard temperature and pressure, it is a colorless gas with a distinctively pungent, suffocating odor. Most people can detect its smell at concentrations as low as 5 parts per million (ppm), a natural warning sign that should never be ignored. Lighter than air, it will rise and dissipate in open, well-ventilated areas, but it can accumulate in enclosed or low-lying spaces, creating unseen pockets of high concentration.

Its chemical properties make it both an excellent refrigerant and a hazardous material. As a refrigerant, it has a high latent heat of vaporization, meaning it can absorb large amounts of heat as it evaporates, making it highly efficient for cooling applications. However, it is also caustic and can cause severe irritation or chemical burns upon contact with moist tissues like the eyes, skin, and respiratory tract. At very high concentrations, it can be fatal. This inherent risk profile is the fundamental reason why a reliable ammonia gas monitor is not an optional accessory but a core component of any facility’s safety infrastructure.

Industrial Applications: Where is Ammonia Used?

The use of ammonia is vast and varied, extending far beyond the common association with cleaning products. Its primary application, consuming over 80% of global production, is in agriculture as a fertilizer, providing a vital source of nitrogen for crops. Think of the immense food production systems that sustain our global population; ammonia is at their very heart.

In the industrial sphere, its role is equally significant.

- Refrigeration: Large-scale industrial refrigeration systems, such as those in food processing plants, cold storage warehouses, and beverage production facilities, widely use anhydrous ammonia (R717) for its superior thermodynamic properties. A leak in one of these massive systems can release a catastrophic amount of gas very quickly.

- Chemical Manufacturing: Ammonia is a building block for countless other chemicals. It is a precursor to nitric acid, which is used to make explosives like TNT and fertilizers like ammonium nitrate. It is also used in the production of plastics, synthetic fibers (like nylon), pharmaceuticals, and dyes.

- Water and Wastewater Treatment: It is used in the form of chloramine for water purification, serving as a more stable disinfectant than free chlorine.

- Energy and Power: Emerging applications in 2025 see ammonia being explored as a carbon-free fuel and a medium for hydrogen storage, which could drastically increase its transport and use in the coming years (International Energy Agency, 2024).

Each of these applications presents a unique set of risks and, consequently, requires a tailored approach to detection. The potential for a leak in a sprawling chemical plant is different from a slow seep in a contained refrigeration unit.

Health and Safety Implications: Why Detection is Non-Negotiable

The human body’s response to ammonia is immediate and severe. Exposure to even low concentrations can cause irritation to the eyes, nose, and throat. As the concentration increases, the effects become more pronounced, leading to coughing, wheezing, and difficulty breathing as the gas damages the respiratory tract. Prolonged exposure or contact with high concentrations can cause irreversible lung damage, blindness, or death.

Regulatory bodies like the Occupational Safety and Health Administration (OSHA) in the United States have established strict exposure limits to protect workers. These limits are not arbitrary numbers; they are based on toxicological data and represent levels at which workers can be exposed without suffering adverse health effects. The responsibility of an employer is to ensure that these limits are never breached. This is where the ammonia detection systems come into play. They are the silent sentinels, the unbiased observers that provide the data needed to protect human life. Their function is to make the invisible visible, to give a voice to a silent threat before it can cause harm.

Check 1: Define Your Application and Environment

The journey toward selecting the appropriate ammonia gas monitor begins not with a product catalog, but with introspection and a deep analysis of your own operational reality. The most technologically advanced detector is rendered useless if it is mismatched to its intended purpose or environment. One must approach this first check with the precision of an engineer and the foresight of a safety strategist.

Fixed vs. Portable: Situational Needs Dictate the Form

The first fundamental choice is between a fixed system and a portable device. This decision is not based on preference but on function. Imagine you are tasked with protecting the people within a large facility. Your strategy must be twofold: area monitoring and personal monitoring.

Fixed Ammonia Detection Systems are the guardians of a space. They are permanently installed in locations where a risk of an ammonia leak is constant or probable. Think of them as smoke detectors for toxic gas. Key locations include:

- Refrigeration equipment rooms (compressor rooms)

- Areas around valves, flanges, and pumps

- Ventilation exhausts

- Large ammonia storage tanks

These systems are designed for continuous, 24/7 operation. They are typically wired into a central control panel that can trigger alarms, activate ventilation systems, or initiate emergency shutdowns. They provide a protective perimeter and an early warning for the entire area.

Portable Ammonia Detectors, in contrast, are the personal protectors of individual workers. A portable ammonia detectors is a handheld or belt-clipped device that a worker carries into a potentially hazardous area. Its purpose is to protect that individual’s breathing zone. Consider these scenarios where a ammonia gas detector portable is indispensable:

- Confined space entry for maintenance or inspection.

- Routine walk-throughs and leak-seeking (pinpointing a leak source).

- Emergency response situations.

- As a secondary layer of protection for workers in areas with fixed detectors.

The choice is not always one or the other; a comprehensive safety program often employs both. Fixed systems monitor the environment, while portable units protect the person moving within that environment.

Analyzing the Operational Environment: Temperature, Humidity, and Pressure

An ammonia gas sensor is a sensitive instrument, and its performance can be significantly influenced by the ambient conditions. A failure to account for these variables can lead to inaccurate readings, false alarms, or, most dangerously, a failure to alarm.

- Temperature: Extreme temperatures, both hot and cold, can affect the sensor’s response and lifespan. Electrochemical sensors, a common type, contain a liquid electrolyte that can freeze at low temperatures or evaporate at high temperatures, leading to failure. When selecting a device, you must verify its specified operating temperature range against the conditions it will face. Will it be in a frozen storage warehouse or a hot engine room?

- Humidity: High humidity can lead to condensation on sensor surfaces, potentially blocking the gas path or causing short circuits. Conversely, very low humidity can dry out the electrolyte in certain sensors. Some sensor technologies are more resilient to humidity fluctuations than others.

- Pressure: Changes in atmospheric pressure can affect the output of some sensor types, particularly electrochemical sensors. For applications at high altitudes or in pressurized environments, it is vital to choose a monitor that is either immune to pressure changes or has compensation features.

Identifying Potential Cross-Interference Gases

Few industrial environments contain only one chemical. An ammonia gas sensor is designed to react to ammonia, but it may also react to other chemicals present in the atmosphere. This phenomenon is known as cross-interference, and it can be a significant source of false readings.

For example, an electrochemical ammonia sensor might show a positive reading when exposed to other gases like hydrogen sulfide (H₂S) or sulfur dioxide (SO₂). It is therefore necessary to conduct an inventory of all chemicals used or produced in the area where the ammonia detector will be deployed.

The manufacturer’s specifications for any potential ammonia gas monitor should include a detailed cross-interference chart. This chart will list various gases and show the sensor’s response to them. If a known interferent is present in your facility, you must select a sensor technology that is less susceptible to it or employ filtering technology to ensure the readings are specific to ammonia. Ignoring cross-interference is to risk either complacency from frequent false alarms or a tragically missed true alarm.

Check 2: Scrutinize the Ammonia Gas Sensor Technology

At the heart of every ammonia gas monitor lies the sensor itself. This tiny component is responsible for the critical task of converting the presence of a chemical into a measurable electrical signal. The technology used in the sensor determines the monitor’s performance characteristics, including its specificity, sensitivity, lifespan, and cost. Understanding the fundamental differences between these technologies is not merely an academic exercise; it is a practical necessity for making a sound choice.

| Sensor Technology | Principle of Operation | Typical Range (ppm) | Advantages | Disadvantages | Best For |

| Electrochemical (EC) | Gas diffuses into the sensor and reacts at an electrode, generating a current proportional to the gas concentration. | 0-100, 0-1000+ | Low power, good resolution, relatively low cost. | Limited lifespan (1-3 years), cross-sensitivity, affected by temperature/humidity. | General purpose safety, both fixed and portable ammonia detectors. |

| Metal Oxide (MOS) | Gas adsorbs onto a heated semiconductor surface, changing its resistance. | 0-1000 | Long lifespan (5-10 years), detects low ppm levels, robust. | High power consumption, non-specific (reacts to many gases), requires warm-up time. | Low-level leak detection in clean environments. |

| Infrared (IR) | Measures the absorption of infrared light at a specific wavelength characteristic of the NH₃ molecule. | 0-100% LEL, 0-1000+ ppm | Highly specific, long lifespan (10+ years), immune to poisoning, low maintenance. | Higher initial cost, may not detect other gases, performance affected by condensation. | High-concentration monitoring, harsh environments, critical process control. |

| Photoionization (PID) | High-energy UV light ionizes the gas molecules, and the resulting current is measured. | 0.1-2000 | Very sensitive to low ppm/ppb levels, fast response. | Non-specific (detects many VOCs), lamp has limited lifespan, affected by high humidity. | Hazmat response, industrial hygiene, detecting low-level toxic exposures. |

Electrochemical (EC) Sensors: The Industry Workhorse

Electrochemical sensors are the most widely used technology in portable and fixed toxic gas detectors, including those for ammonia. To understand how they work, you can think of them as a tiny, gas-powered battery. The sensor contains two or three electrodes immersed in an electrolyte. When ammonia gas diffuses into the sensor, it undergoes an electrochemical reaction (oxidation or reduction) at the surface of the “sensing electrode.” This reaction generates a small electrical current that is directly proportional to the gas concentration.

Their popularity stems from a good balance of performance and cost. They offer high resolution at low ppm levels, consume very little power (making them ideal for battery-operated portable units), and are relatively inexpensive. However, their nature presents limitations. The electrolyte can be consumed over time, giving them a finite lifespan, typically 1 to 3 years. They are also susceptible to cross-interference from other gases and their performance can drift with changes in temperature and humidity. Regular calibration is not just recommended; it is essential for reliable operation.

Metal Oxide Semiconductor (MOS) Sensors: For Low-Level Leak Detection

MOS sensors operate on a different principle. They utilize a ceramic bead coated with a metal oxide material, which is heated to a high temperature (around 300-400°C). In clean air, oxygen from the atmosphere adsorbs onto the surface, creating a resistive barrier. When a target gas like ammonia comes into contact with the heated surface, it reacts with the adsorbed oxygen, which in turn lowers the electrical resistance of the sensor. This change in resistance is measured and converted into a gas concentration reading.

The primary advantage of a MOS-based ammonia gas sensor is its long operational life, often exceeding five years. They are also highly sensitive to low concentrations of ammonia, making them excellent for early warning leak detection. The main drawback is their lack of specificity. The heated surface will react with a wide range of combustible and reducing gases, not just ammonia. This makes them unsuitable for applications where other volatile compounds are present. They also require a significant amount of power to heat the bead and need a warm-up period to stabilize before providing accurate readings.

Catalytic Bead (Pellistor) Sensors: A Niche Application

While primarily used for detecting combustible gases, catalytic bead sensors can be configured for high concentrations of ammonia. These sensors work by measuring the temperature change caused by the catalytic oxidation of the gas on a heated bead. Ammonia, while not flammable in the typical sense, will decompose at the high temperatures on the catalyst surface. This technology is generally not sensitive enough for toxic exposure monitoring at the ppm level and is reserved for applications measuring ammonia in the percent-by-volume range, which is far above any toxic limit.

Photoionization Detectors (PID): For Broad-Spectrum VOCs and Low NH₃

PIDs are a different class of sensor altogether. They use a high-energy ultraviolet (UV) lamp to ionize gas molecules. When a molecule with an ionization potential lower than the lamp’s energy passes through, it is stripped of an electron, creating a positively charged ion. These ions generate a current that is measured by the detector.

PIDs are exceptionally sensitive, capable of detecting some chemicals down to parts per billion (ppb) levels. They have a very fast response time, making them excellent for emergency response and hazardous materials incidents. Their main limitation is that they are completely non-specific. A PID will respond to any gas it can ionize. While they can detect ammonia (which has an ionization potential of 10.16 eV), they will also detect a vast array of Volatile Organic Compounds (VOCs). They are best used as broad-range screeners or in situations where ammonia is the only known contaminant.

Infrared (IR) Sensors: High Specificity and Longevity

Infrared sensors offer a highly sophisticated and robust method for gas detection. The principle is based on the fact that different gas molecules absorb infrared light at unique, characteristic wavelengths. An IR sensor passes a beam of IR light through the gas sample to a detector. A specific optical filter is placed in front of the detector that only allows the wavelength of light absorbed by ammonia to pass through. The amount of light that reaches the detector is inversely proportional to the gas concentration—more ammonia means less light gets through.

The greatest strengths of an IR ammonia gas sensor are its specificity and stability. Because it is tuned to the unique absorption signature of ammonia, it is virtually immune to cross-interference from other gases. It does not get “poisoned” by contaminants and does not have components that are consumed during measurement, giving it a very long lifespan (often over 10 years). The primary disadvantages are a higher initial purchase price and the fact that high humidity or condensation can interfere with the optical path, potentially affecting the reading. Despite the cost, for critical applications where accuracy and reliability are paramount, an IR sensor is often the superior choice.

Check 3: Evaluate Detection Range, Accuracy, and Response Time

Once you have a grasp of the sensor technologies, the next step is to examine their performance specifications with the rigor of a scientist. These numbers—range, accuracy, and response time—are not just abstract figures on a data sheet. They are the defining characteristics that determine whether a monitor can fulfill its primary function: to provide a timely and trustworthy warning that allows for protective action.

Matching the Range to Regulatory Limits (TLV, STEL, IDLH)

The detection range of an ammonia detector must encompass the specific concentrations that are relevant to safety and regulation. An instrument that measures from 0-1000 ppm is of little use if you need to precisely monitor worker exposure around the 25 ppm level. You must be familiar with the key occupational exposure limits (OELs).

| Exposure Limit | Agency (USA Example) | Typical Value for Ammonia (ppm) | Meaning |

| TLV-TWA (Threshold Limit Value – Time-Weighted Average) | ACGIH | 25 ppm | The average concentration a worker can be exposed to over an 8-hour workday without adverse effects. |

| STEL (Short-Term Exposure Limit) | ACGIH | 35 ppm | The maximum concentration a worker can be exposed to for a continuous 15-minute period without suffering irritation or long-term damage. |

| PEL (Permissible Exposure Limit) | OSHA | 50 ppm | The legal limit for an 8-hour TWA exposure. |

| IDLH (Immediately Dangerous to Life or Health) | NIOSH | 300 ppm | The concentration from which a worker could escape without suffering irreversible health effects or symptoms that would impair escape. |

ACGIH: American Conference of Governmental Industrial Hygienists; OSHA: Occupational Safety and Health Administration; NIOSH: National Institute for Occupational Safety and Health.

Your ammonia gas monitor must be able to accurately measure concentrations at and below these critical thresholds. A typical requirement is for a monitor to have alarms set at the TWA and STEL levels. Therefore, a monitor with a range of 0-100 ppm is often suitable for personal safety applications. For leak detection in equipment rooms, a higher range (e.g., 0-1000 ppm or more) might be necessary to capture the full scale of a potential release.

The Pursuit of Accuracy: Understanding Tolerances and Drift

Accuracy defines how close a monitor’s reading is to the true concentration of the gas. No instrument is perfectly accurate. Manufacturers will specify an accuracy tolerance, often as a percentage of the reading or a fixed ppm value (e.g., ±10% of reading or ±2 ppm). It is vital to understand that this specified accuracy is only valid under specific conditions and immediately following a successful calibration.

Over time, all sensors experience “drift,” a gradual change in their output even in clean air. This can be caused by aging components, exposure to contaminants, or environmental changes. This is why regular calibration is not just a best practice but a fundamental requirement. A sensor that has drifted can either under-report a dangerous concentration (a false sense of security) or over-report it (leading to nuisance alarms and a loss of trust in the device). When evaluating an ammonia detector, look for specifications on long-term drift and consider the stability of the chosen sensor technology.

T90 Response Time: How Quickly Does the Monitor React?

Response time is a measure of how quickly the monitor reacts to a change in gas concentration. It is typically specified as “T90,” which means the time it takes for the sensor to reach 90% of its final reading when exposed to a step change in gas concentration.

Imagine a worker walking into a room where an ammonia leak has just started. A monitor with a T90 of 60 seconds will take a full minute to display a near-accurate reading of the danger. A monitor with a T90 of 15 seconds provides a much faster warning. For personal safety, a rapid response is paramount. For fixed systems monitoring a large, stable area, a slightly longer response time might be acceptable.

The response time is influenced by several factors: the sensor technology itself (PIDs are very fast, EC sensors are moderately fast), the design of the housing, and the presence of any filters over the sensor. Always confirm that the T90 response time of a potential ammonia gas monitor is adequate for the speed at which a hazardous situation could develop in your application.

Check 4: Assess Certification, Compliance, and Ingress Protection (IP) Ratings

An ammonia detector is not just a piece of electronic equipment; it is a life-safety device. As such, it is subject to rigorous testing and certification to ensure it will perform reliably, especially in hazardous environments. Navigating these certifications can seem like decoding an alphabet soup of acronyms, but understanding them is essential for ensuring both safety and legal compliance.

Navigating the Maze of Safety Certifications (ATEX, IECEx, UL)

If an ammonia leak occurs, the gas itself can create a potentially explosive atmosphere, especially at concentrations above its Lower Explosive Limit (LEL) of about 15% by volume. Any electronic device used in such an area must be designed so that it cannot become an ignition source (e.g., from a spark or a hot surface). This is the domain of “intrinsic safety” and “explosion-proof” design.

- ATEX: This is the European Union’s directive for equipment used in explosive atmospheres. Products bearing an ATEX certification have been tested and approved for safe use in specific hazardous zones. The marking will specify the level of protection and the types of hazardous environments (gas or dust) it is suited for.

- IECEx: This is an international certification system. While ATEX is a legal requirement within the EU, IECEx provides a globally recognized certificate of conformity. Many modern devices carry both ATEX and IECEx certifications, simplifying their use across different regions.

- UL / CSA: In North America, Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) provide similar certifications for hazardous locations (“HazLoc”). A UL or CSA mark indicates that the product meets the required safety standards for the North American market.

When procuring an ammonia detection system, you must verify that its certifications match the hazardous area classification of the location where it will be installed. Using a non-certified device in a classified zone is a serious safety violation and a significant legal liability.

Ensuring Compliance with OSHA, EPA, and Local Regulations

Beyond certifications for hazardous locations, you must also consider compliance with occupational health and environmental regulations. In the United States, OSHA’s Process Safety Management (PSM) standard (29 CFR 1910.119) applies to facilities that handle large quantities of hazardous chemicals, including ammonia. The PSM standard requires a comprehensive management program that includes, among many other things, procedures and equipment to ensure the mechanical integrity of systems and to detect releases.

The Environmental Protection Agency (EPA) has its own Risk Management Program (RMP) rule, which also applies to facilities with large ammonia inventories. Both PSM and RMP implicitly require reliable gas detection as part of an overall strategy to prevent and mitigate catastrophic releases. Your choice of an ammonia gas monitor should be justifiable within the framework of these programs. This often involves selecting devices with features like data logging and relay outputs that can integrate into the plant’s overall safety instrumented system.

Demystifying Ingress Protection (IP) Ratings

The industrial world is often a dirty and wet place. An ammonia detector must be able to withstand the environmental rigors of its intended location. The Ingress Protection (IP) rating is a standardized system that classifies the degree of protection provided by an enclosure against the intrusion of solid objects (like dust) and liquids (like water).

An IP rating is given as a two-digit number, such as IP67.

- The first digit (0-6) indicates the level of protection against solid particles. A ‘6’ means the enclosure is completely dust-tight.

- The second digit (0-8) indicates the level of protection against liquids. A ‘5’ means it is protected against jets of water from any direction. A ‘7’ means it can be temporarily submerged in water.

For an ammonia gas detector portable carried by a worker who may be exposed to rain, a rating of IP65 or higher is advisable. For a fixed detector in a wash-down area of a food processing plant, a rating of IP66 or IP67 would be necessary to ensure it survives regular cleaning procedures. Choosing a device with an inadequate IP rating is a recipe for premature failure.

Check 5: Consider Data Logging, Connectivity, and System Integration

In the modern industrial landscape, an ammonia detector is more than just an alarm bell. It is a data point, a node in a network of information that can be used to move from a reactive safety posture to a proactive one. The ability to record, transmit, and integrate data is no longer a luxury feature; it is a core component of a sophisticated safety and operational management strategy (Theofanos et al., 2024).

The Value of Data: Logging for Compliance and Incident Analysis

Most modern portable and fixed ammonia detectors have onboard data logging capabilities. They can record gas concentrations, alarm events, calibration records, and other information at regular intervals. The value of this data is immense.

- Compliance Reporting: Data logs provide a verifiable record of exposure levels over time. This is invaluable for demonstrating compliance with OSHA and other regulatory bodies. You can generate reports showing that worker exposures have remained below the TWA and STEL limits.

- Incident Investigation: In the event of an alarm or an exposure incident, the data log provides a second-by-second account of what happened. When did the concentration start to rise? How high did it get? How long did the event last? This information is critical for root cause analysis and for implementing corrective actions to prevent a recurrence.

- Exposure Tracking: For industrial hygiene purposes, data from a

portable ammonia detectorscan be used to create a detailed exposure profile for individual workers or job roles. This can help identify high-risk tasks and justify changes in work practices or engineering controls.

When evaluating a monitor, consider the capacity of its data log, the ease of downloading the data (e.g., via USB, Bluetooth, or docking station), and the software used to analyze and report it.

Wireless Connectivity and Remote Monitoring Capabilities

The advent of wireless technology has transformed gas detection. Many modern ammonia detection systems now offer wireless connectivity, allowing them to transmit data in real-time to a central location.

This capability is particularly powerful for portable detectors. Imagine a team of workers entering a large vessel for maintenance. With wireless-enabled portable units, a safety attendant outside the confined space can monitor the atmospheric conditions for the entire team in real-time on a single screen. If any worker’s detector alarms, the attendant knows immediately who is in trouble and what their gas reading is. This level of situational awareness dramatically improves the safety of lone workers or teams operating in complex environments.

For fixed systems, wireless communication can simplify installation by eliminating the need for long and expensive signal wiring back to a central controller. This can be a significant cost saving, especially in large or existing facilities.

Integrating the Ammonia Detector into Plant-Wide Safety Systems (DCS, SCADA)

A fixed ammonia gas monitor should not operate in isolation. Its true power is realized when it is integrated into the facility’s broader control and safety infrastructure, such as a Distributed Control System (DCS) or a Supervisory Control and Data Acquisition (SCADA) system.

This integration is typically achieved through standard industrial communication protocols. The ammonia detector can send its readings and alarm status to the main control room, where an operator can see the information alongside other process variables like temperature, pressure, and flow. This provides a holistic view of the plant’s status.

Furthermore, integration allows for automated safety actions. For example, a high-level ammonia alarm from a detector in a compressor room could be programmed to automatically:

- Trigger audible and visual alarms throughout the plant.

- Activate an emergency ventilation system.

- Shut down the refrigeration compressor.

- Close automated isolation valves to stop the source of the leak.

This level of automation removes the potential for human error in an emergency and executes a pre-planned safety response much faster than a person could. When selecting a fixed ammonia detector, inquire about its output options (e.g., 4-20mA analog output, Modbus, HART, relay contacts) and ensure they are compatible with your existing control systems. Exploring a range of advanced gas analysis solutions can provide insight into the possibilities of system integration.

Check 6: Plan for Calibration, Maintenance, and Lifecycle Cost

The purchase price of an ammonia gas monitor is only the beginning of the story. A safety device is not a one-time purchase but a long-term commitment. A thorough evaluation must look beyond the initial capital expenditure and consider the total cost of ownership (TCO) over the device’s entire lifecycle. This includes the recurring costs of maintenance, calibration, and sensor replacement. A failure to budget for these activities is a failure to maintain the integrity of your safety system.

The Ritual of Calibration: Frequency and Procedure

Calibration is the process of verifying and adjusting a monitor’s response to a known concentration of gas. It is the single most important maintenance task for ensuring a detector’s accuracy. A bump test, a brief exposure to a challenge gas to verify sensor response and alarm function, should be performed before each day’s use for portable units. A full calibration, which adjusts the sensor’s output, should be performed according to the manufacturer’s recommendations, typically every 3 to 6 months.

When assessing a device, consider the following:

- Calibration Procedure: Is the calibration process simple and intuitive, or is it complex and requires specialized training? Some modern detectors feature automated calibration routines that can be performed by placing the device in a docking station.

- Cost of Calibration Gas: Ammonia calibration gas has a limited shelf life and can be costly. The volume of gas required for each calibration will impact the ongoing operational cost.

- Calibration Services: Does the supplier offer calibration services, or will you need to perform it in-house? If in-house, do you have the trained personnel and equipment to do so correctly?

Skipping or delaying calibration is akin to driving a car without ever checking the brakes. The device may appear to be working, but you have no assurance that it will perform when you need it most.

Sensor Lifespan and Replacement Schedules

The sensing element within an ammonia detector is a consumable component. As discussed previously, different sensor technologies have different expected lifespans. An electrochemical ammonia gas sensor might last 1-3 years, while an infrared sensor could last over 10 years.

The cost of replacement sensors is a major component of the TCO. A monitor with a low initial purchase price but an expensive, short-lived sensor may end up being far more costly over a five-year period than a device with a higher initial price but a long-life sensor. You must factor the cost and frequency of sensor replacement into your financial planning.

Additionally, consider the ease of replacement. Can a user easily replace the sensor in the field, or does the entire unit need to be sent back to a service center? Field-replaceable sensors minimize downtime and keep your safety equipment in service.

Calculating the Total Cost of Ownership (TCO) Beyond the Purchase Price

To make a truly informed financial decision, you must calculate the TCO. This provides a more complete picture than simply comparing the initial prices of different models. A basic TCO calculation over a 5-year period might include:

TCO = Initial Purchase Price + (Annual Calibration Cost x 5) + (Cost of Replacement Sensors x Number of Replacements in 5 years) + (Annual Maintenance/Service Contract Cost x 5)

Let’s consider a simplified example.

- Monitor A: Costs $800. Uses an EC sensor that costs $250 and needs replacement every 2 years. Annual calibration cost is $100.

- Monitor B: Costs $1,500. Uses an IR sensor with a 10-year life (no replacement needed in 5 years). Annual calibration cost is $100.

TCO for Monitor A (5 years): $800 (initial) + ($100 x 5) (calibration) + ($250 x 2) (sensors) = $800 + $500 + $500 = $1,800

TCO for Monitor B (5 years): $1,500 (initial) + ($100 x 5) (calibration) + $0 (sensors) = $1,500 + $500 = $2,000

In this simplified case, Monitor A appears more cost-effective over five years. However, if the IR sensor in Monitor B also requires less frequent calibration or eliminates false alarms that cause costly process shutdowns, the calculation could easily shift in its favor. The TCO analysis forces a more disciplined and realistic evaluation of the long-term financial commitment.

Check 7: Select a Reputable Supplier and Support System

The final check in this comprehensive process moves beyond the hardware and into the human dimension of the purchase. The supplier you choose is not just a vendor; they become your partner in safety. The quality of their support, the depth of their expertise, and their commitment to service are as vital as the specifications of the ammonia gas monitor itself. A top-tier product from an unreliable supplier is a poor investment.

The Importance of Technical Expertise and Application Support

The world of gas detection is complex. You are not just buying a box; you are implementing a solution to a specific safety problem. A reputable supplier will have a team of technical experts who can help you navigate this complexity.

They should be able to:

- Discuss your application in detail and understand your unique challenges.

- Help you choose the right sensor technology based on your environment and potential cross-interferences.

- Advise on the optimal placement of fixed detectors based on airflow patterns and potential leak sources.

- Provide guidance on setting appropriate alarm levels based on regulations and best practices.

This pre-sales consultation is invaluable. It helps prevent costly mistakes and ensures that the solution you purchase is genuinely fit for purpose. Do not hesitate to ask probing questions about their experience with applications similar to yours. Their ability to provide clear, confident, and knowledgeable answers is a strong indicator of their competence.

Evaluating Warranty, Service, and Availability of Spares

A safety device is only useful when it is working. When a monitor fails or requires service, you need a supplier who can provide prompt and effective support to minimize downtime.

- Warranty: Scrutinize the warranty policy. What does it cover, and for how long? Note that the warranty period for the instrument itself may be different from the warranty on the consumable sensors. A three-year warranty on a monitor is of limited value if the sensor is only covered for one year.

- Service and Repair: What is the process for service and repair? Do they have local or regional service centers, or must the unit be shipped internationally? What is the typical turnaround time for a repair? A monitor that is out for service for six weeks is a significant gap in your safety coverage.

- Availability of Spares: How readily available are spare parts like replacement sensors, calibration gas, and filters? A supplier with a robust inventory of industrial process instruments and their associated spare parts can ensure that you can quickly get what you need to keep your equipment operational. Delays in obtaining a replacement sensor can leave you unprotected.

Building a Partnership for Long-Term Safety

Ultimately, the relationship with your supplier should be viewed as a long-term partnership. A good partner will not disappear after the sale is complete. They will be a resource for you throughout the lifecycle of the equipment.

This includes providing ongoing training for your staff, notifying you of firmware updates or product improvements, and being available to answer questions that arise during day-to-day operation. They should be invested in your success because your safety is their business. When you select a supplier, you are also selecting the support system that will stand behind your ammonia detection program for years to come. Choose wisely, as this partnership is a cornerstone of a sustainable culture of safety.

FAQ

Related Products

Choosing an ammonia monitor is a serious undertaking. It’s not as simple as quickly glancing at a price tag or feature list. It requires a thoughtful and systematic investigation of the specific nature of the risk, the nuances of the operating environment, and the capabilities of existing technology.

By methodically completing seven key checks—defining the application scenario, carefully reviewing the sensor, evaluating performance metrics, ensuring compliance, planning integration, calculating total cost, and selecting the right partner—the procurement process can be transformed into a strategic security measure.

Sino-Inst helps you create an environment that makes the invisible threat of ammonia visible and controllable, allowing you to operate with confidence.

More Resources

-

How Do You Test for Helium?

Helium is a unique element. It is the second lightest element in the universe, chemically inert, non-flammable, and possesses the smallest atomic size…

-

How Do I Get My Carbon Monoxide Detector to Stop Chirping? (2026 Guide)

The piercing sound of a carbon monoxide (CO) detector chirping is one of the most stressful noises a homeowner can experience. It often…

-

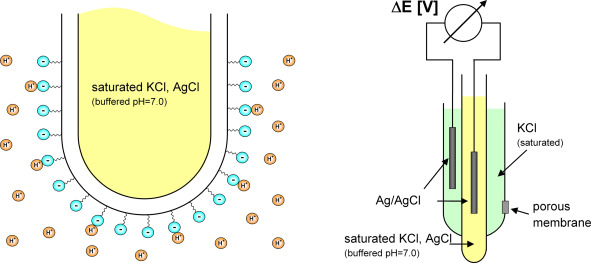

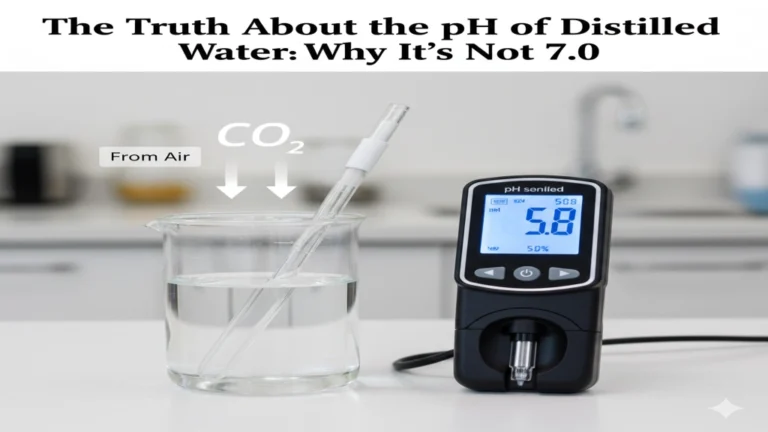

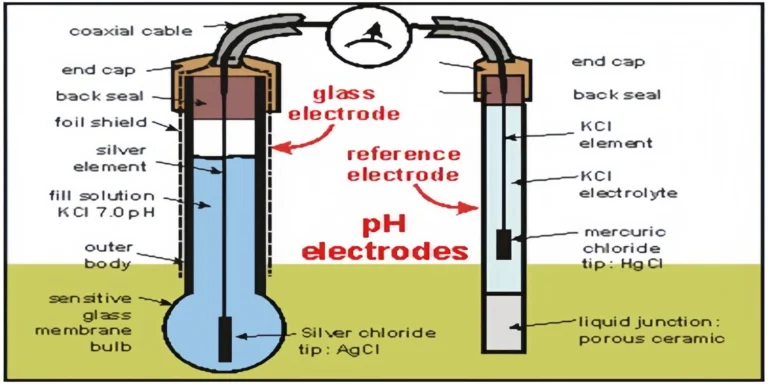

Choosing a pH Meter for Water:The Professional Guide to(2026)

A pH meter for water is the pulse of chemical equilibrium in water treatment and industrial processing, far more than just a digital…

-

9 Best Personal Gas Monitoring Devices 2026

In the industrial world, safety is not a luxury; it is a prerequisite for operation. As we move into 2026, the technology driving…

-

What Is Dissolved Oxygen in Water? The Ultimate Guide to Monitoring(2026)

When we talk about water quality, we often focus on what we can see, like clarity, or what we can taste, like salt….

-

Mastering Safety: How to Check Gas Level in Confined Space?

The Critical Importance of Atmospheric Testing Working in industrial environments often requires entering areas that are not designed for continuous occupancy. These locations,…

.png)