Whether you are managing an industrial wastewater plant, running a high-tech shrimp farm, or maintaining a commercial swimming pool, your success depends on one thing: Water Quality.

If you get these numbers right, you have a safe, profitable operation. If you get them wrong, you face fines, dead stock, or safety hazards.

But with dozens of different parameters to track—from COD to pH to Conductivity—it is easy to get overwhelmed. Which ones actually matter? Which ones should you automate?

This guide moves beyond the dictionary definitions to give you a practical operating framework used by water treatment experts worldwide.

What Are water quality parameters?

Before we dive into strategy,let’s define the basics.

Water quality parameters are the physical,chemical,and biological characteristics used to measure the health and safety of water.They act as the “vital signs” of your water system.

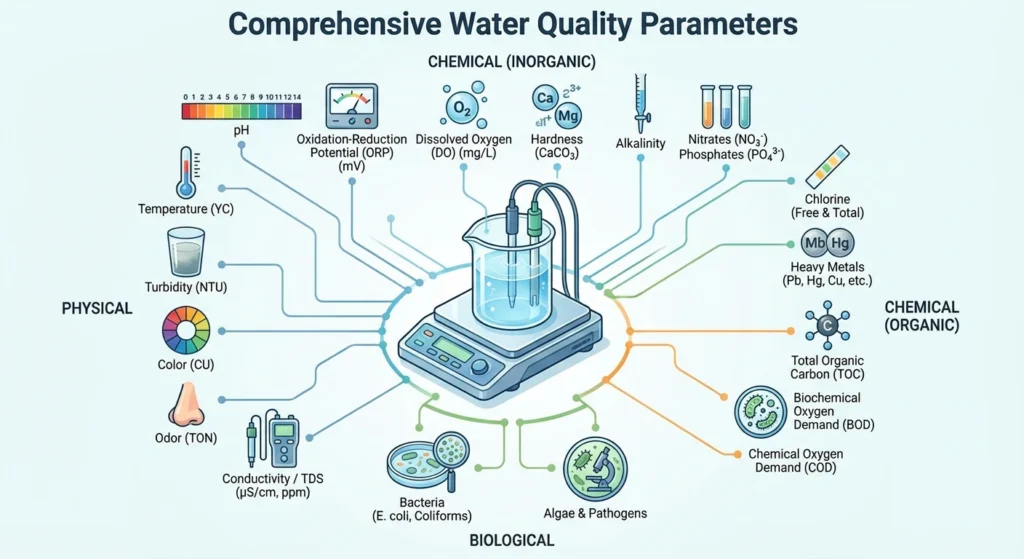

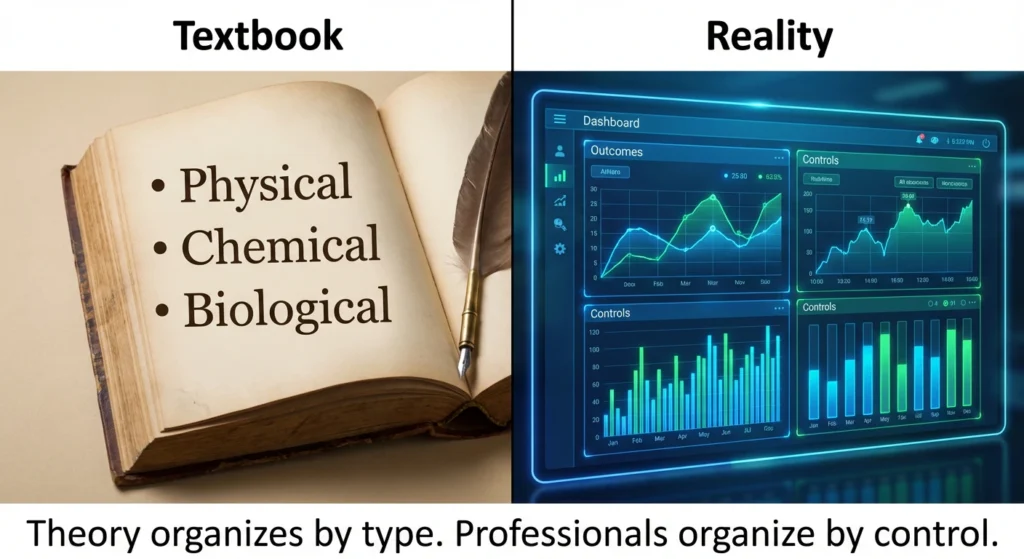

Traditionally,science textbooks categorize them into three standard groups:

- Physical: Temperature, Turbidity, Conductivity (EC), Color.

- Chemical: pH, Dissolved Oxygen (DO), Chemical Oxygen Demand (COD), Ammonia, Chlorine.

- Biological: Bacteria (E. coli), Algae, Plankton.

While this classification is scientifically correct, it is not very useful for daily operations.

Knowing that “Ammonia” is a chemical parameter doesn’t help you when your fish are dying or your discharge permit is denied. As a professional, you need a new way to categorize these metrics—one based on Action and Control.

Decision Table: Monitoring vs. Automatic Control

Not every water quality test requires a dosing pump. Some are for observation, while others are critical for closed-loop automation.

Should You Monitor or Control These Water Quality Parameters?

| Parameter | Typical Role | Auto-Control? | Why It Matters |

| pH | Process Variable | Yes | Controls chemical solubility & toxicity. |

| ORP (Redox) | Disinfection Strength | Yes | Real-time measure of “killing power.” |

| Conductivity | Ionic Strength | Sometimes | Controls blowdown and chemical concentration. |

| DO (Oxygen) | Bio-Activity | Yes | Essential for aeration efficiency in bio-tanks. |

| Turbidity | Water Clarity | Usually No | Alerts to filter failure or intake issues. |

The “3 Layers” Framework for Professionals

To manage water effectively,we are re-classifying water parameters into three practical layers:

- Layer 1:The Outcome(The Goal)-The results you are trying to achieve.

- Layer 2: The Control (The Steering Wheel) – The parameters you can actually adjust.

- Layer 3: The Diagnostics (The Dashboard) – The parameters that check system health.

The Secret: Most operators obsess over Layer 1, but smart professionals know that Layer 2 (pH and ORP) is where the battle is actually won.

Layer 1: The Outcome Parameters (The “Scoreboard”)

Layer 1 includes the critical water quality parameters that define your success or failure. But here is the problem: They are “Lagging Indicators.”

Think of these parameters like the score at the end of a game. When you see the final score, the game is over.

- Wastewater (The Risk of Fines): COD & Heavy Metals tell you if your water is safe to discharge. If your COD sensor triggers an alarm, it is usually too late.

- Aquaculture (The Risk of Death): Ammonia (NH₃) is the invisible killer. By the time fish float on the surface, the spike has already happened.

- Pools (The Risk of Safety): Pathogens are only confirmed after a 24-hour lab test. By then, exposure has already occurred.

The Trap: You cannot simply “turn a knob” to adjust these outcomes. To fix the Result (Layer 1), you must control the Cause (Layer 2).

Layer 2: The Control Parameters (Your “Steering Wheel”)

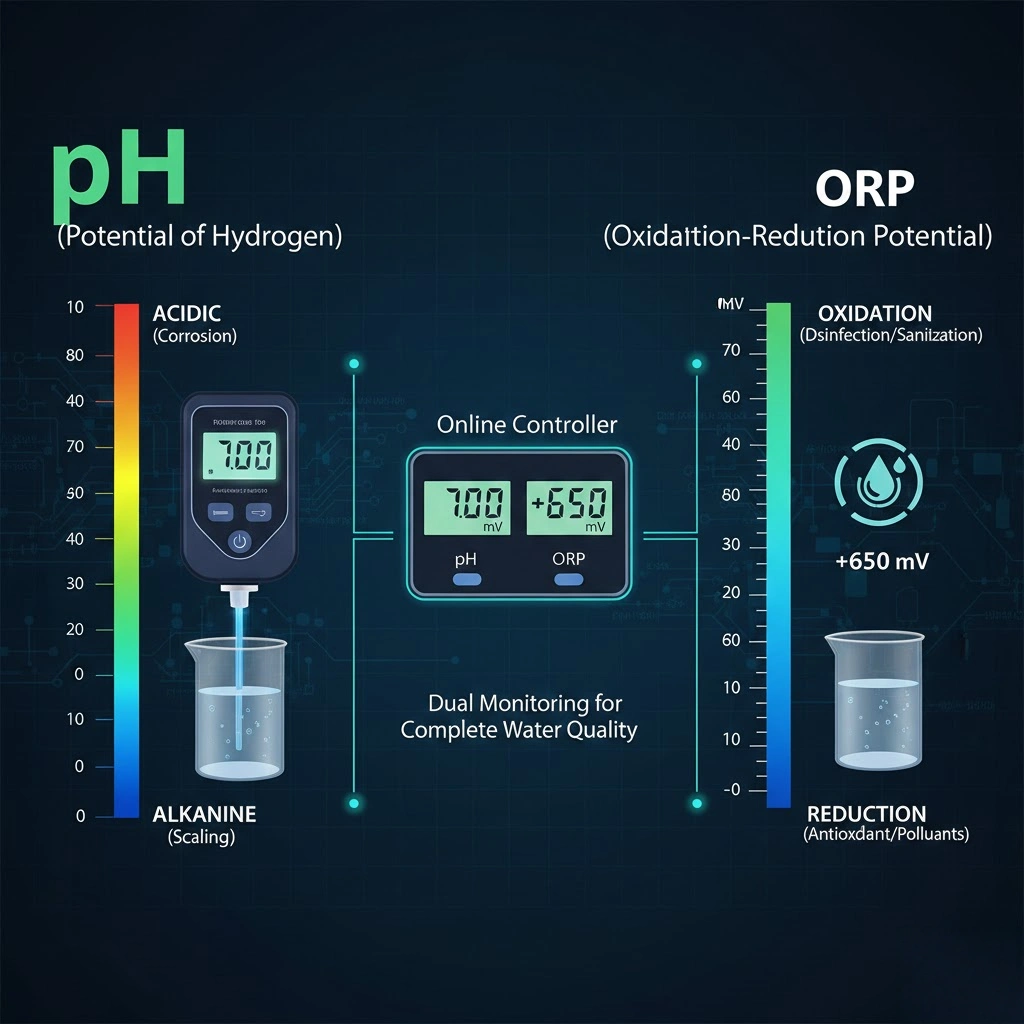

pH and ORP are the two most significant things to look at while treating water around the world. They are the “Steering Wheels” that make your results happen.

1. pH: Water Chemistry’s “Gatekeeper”

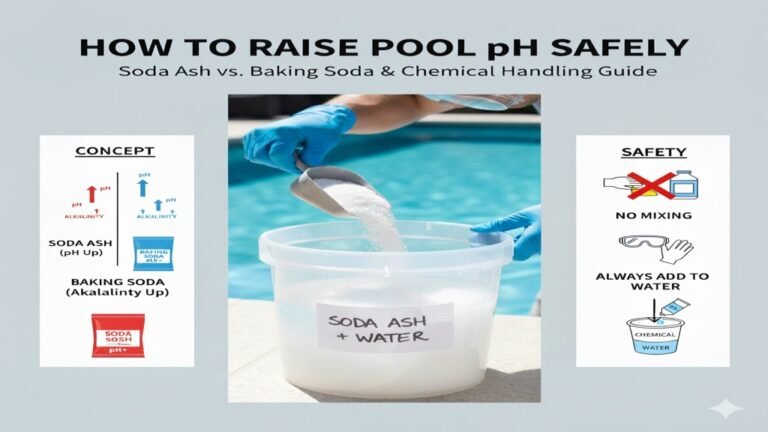

pH in water governs how soluble and poisonous chemicals are. Nickel and other metals only come out of wastewater at certain pH values, such as > 9.0. At a pH of 8.0, chlorine only works 20% of the time in pools.

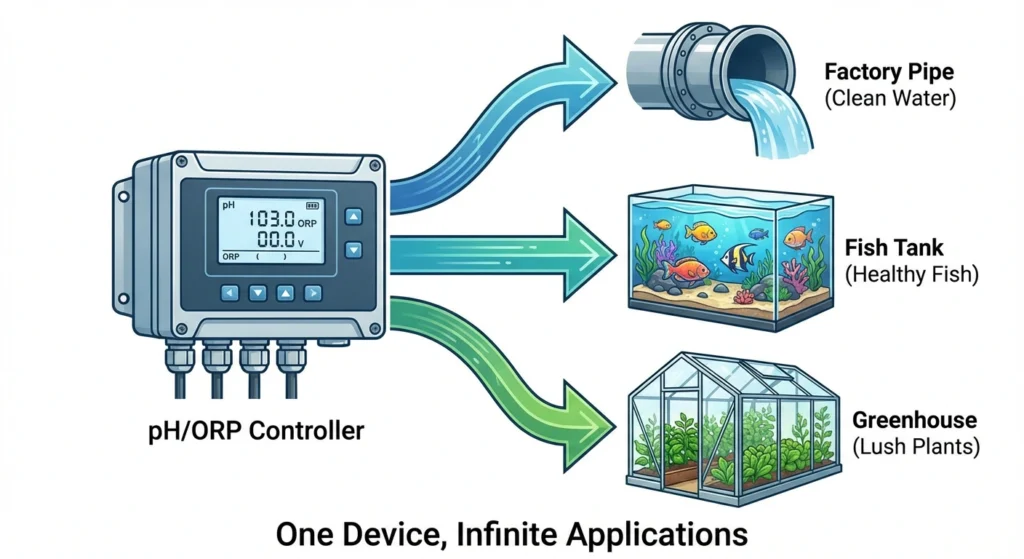

Operational Tip:Professionals utilize high-precision Sino-Inst Online pH Controllers to keep this master variable locked. They automatically dose acids and bases, which keeps your chemistry steady all the time.

2. ORP: The “Truth Teller” of Sanitation

ORP (Oxidation-Reduction Potential) tells you how much “killing power” the water really has in millivolts (mV). ORP is your real-time health bar, whether you’re fighting Legionella in cooling towers or cyanide in plating baths.

Smart Automation: By adding a Sino-Inst ORP Controller, you can dose oxidants exactly. This stops the typical mistake of amateurs giving chemicals too much, which saves you money on reagents and makes sure that the area is clean.

The Hard Truth About Water Control

Across wastewater treatment, aquaculture, and disinfection systems, one pattern is consistent:

If pH and ORP are stable, most other water quality problems never appear.

- pH controls:

- Chemical solubility

- Toxicity transformation

- Disinfection efficiency

- ORP controls:

- Oxidation strength

- Biological activity

- Pathogen destruction

That is why experienced water professionals do not chase COD, ammonia, or bacteria directly.

They lock pH and ORP first — everything else follows.

You cannot directly control the result.

You can only control the chemistry that creates the result.

Layer 3: The Diagnostic Parameters (Your “Dashboard”)

You look to Layer 3 to figure out why your “Steering Wheel” (Layer 2) is having trouble. These parameters show “Why” the system isn’t stable.

- Step 1: Check the temperature.

- Sudden changes can mess up pH readings. Automatic Temperature Compensation (ATC) is built into every Sino-Inst monitor to make sure the data is correct.

- Step 2: Conductivity / TDS

- An increase in EC usually means that chemicals are being overdosed or there are leaks in the system. With good linearity, a Sino-Inst Conductivity Meter helps you keep track of blowdown cycles and salt levels.

- Step 3: Dissolved oxygen (DO) is very important for living things. To keep oxygen levels from dropping too low in aeration tanks or high-density shrimp farms, Sino-Inst Optical DO Sensors provide stable, low-maintenance tracking.

- Step 3: Sensor Health

- Fouled probes cause false control actions

- Uncompensated temperature leads to phantom pH drift

In the fourth step, “sensor health,” faulty probes lead to “phantom drift.” Layer 2 control stays correct as long as you take care of your Sino-Inst electrodes on a regular basis.

In short, Layer 3 doesn’t run the system; it just tells the control system why it’s having trouble.

How to Test Water Quality: 3 Professional Methods

The key to understanding how to test water quality is to balance accuracy and efficiency.

A. Manual Spot Checks (Test Paper and Color Method)

Method: Use test strips or reagents (such as DPD) to obtain numerical values through color comparison.

Applicable: Temporary sampling or low budget scenarios.

Disadvantages: Strong subjectivity, unable to achieve 24/7 monitoring.

B. Portable Digital Meters

Method: Use a handheld water quality test meter for on-site digital reading.

Environmental research, multi-point spot checks, and checking the calibration of online equipment are all examples of things that can be done.

Suggestions: Before each usage, it is a good idea to calibrate with a standard solution to make sure the results are correct.

C. Online Monitoring Systems: Fixed sensors on pipelines let you check the quality of the water in real time.

Aquaculture, industrial effluent, and other situations that need automated dosage management are some of the most relevant.

Some of the benefits are less work for people, automatic warnings, and data that can be traced.

Choosing the Right Gear for Your Application

| Industry / Application | Primary Control Parameter | Recommended Sino-Inst Solution |

| Electroplating & Surface Finishing | pH & ORP | Industrial pH/ORP Controller with heavy-duty, anti-interference electrodes for harsh chemical baths. |

| Municipal Wastewater Treatment | DO & MLSS | Optical Dissolved Oxygen (DO) Sensors + Suspended Solids Analyzers for high-efficiency aeration control. |

| Drinking Water Disinfection | Residual Chlorine | Online Residual Chlorine Analyzers (DPD or Electrode method) to ensure safety and WHO compliance. |

| Reverse Osmosis (RO) & Pure Water | Conductivity / TDS | High-Linearity Conductivity Meters to monitor membrane performance and salt rejection rates. |

| Hydroponics & Precision Ag | pH, EC & Temp | Multi-Parameter Controllers that integrate nutrient dosing and environmental compensation in one unit. |

Conclusion:Stop Guessing,Start Controller

You cannot control the weather,and you cannot predict every production shock load.But you can control your pH and ORP.

If you are still relying on manual testing or waiting for lab results on”Lagging Indicators”like COD,you are gambling with your compliance.By the time you find a problem.

The solution is simple:Stabilize your system at the source.Automate the “Control Layer”,and the results will follow.

FAQ

Related Products

pH/ORP Controllers

Glass Sensor

Plastic-Shell Sensor

Ready to upgrade your peace of mind?

Don’t risk a fine to save a few dollars. Shop our [Industrial pH & ORP Controllers] today. Reliable, precise, and built to keep your water quality parameters perfect, 24/7.

Request a Quote

More Resources

-

The 10 Best Digital carbon monoxide detectors 2026: An Industrial Guide

Carbon monoxide (CO) remains one of the most hazardous invisible threats in industrial, commercial, and residential environments. Colorless, odorless, and tasteless, it requires…

-

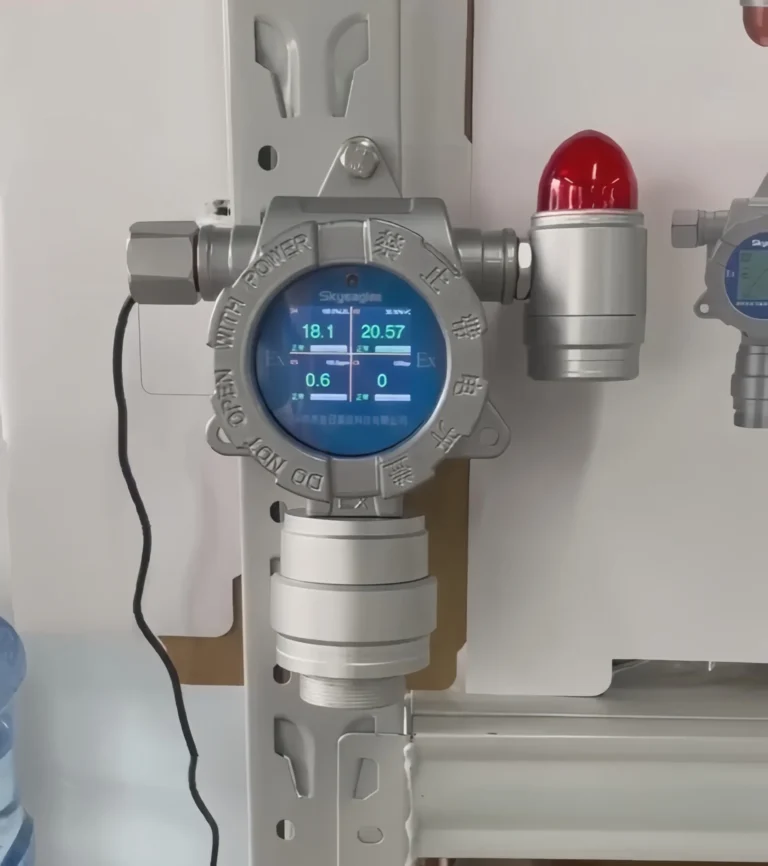

Can gas detectors detect multiple gases simultaneously?

In the complex and often hazardous world of industrial manufacturing, petrochemical processing, and confined space operations, ensuring the safety of personnel is the…

-

Surface Water vs Groundwater: A Comprehensive Guide to Water Quality

In the domains of environmental engineering and industrial water management, knowing the basic differences between surface water vs groundwater is not just an academic…

-

What is the pH of Reverse Osmosis Water? The Complete Science Guide (2026)

If you have ever been curious about ‘what is the pH of reverse osmosis water?’, you are not alone. This is one of…

-

The Top 8 Portable CO Detector for Car Use

Introduction: The Silent Threat in Automotive Cabins Carbon monoxide (CO) is a colorless, odorless, and highly toxic gas generated by the incomplete combustion…

-

6 Best Mass Flow Controller for Liquids: An Expert Technology Guide

In modern industrial automation, pharmaceutical manufacturing, and semiconductor fabrication, the precise control of fluid dynamics is a fundamental requirement. Relying on outdated volumetric…

.png)