Understanding Mass Flow Controllers for Gases

A Mass Flow Controller for gases (MFC) is a precision instrument that measures and controls the flow rate of gases in various industrial and laboratory applications. Unlike volumetric flow controllers, MFCs measure actual mass flow, providing consistent accuracy regardless of temperature or pressure variations.

Complete Navigation Guide

- Understanding Mass Flow Controllers for Gases

- Key Selection Criteria for Gas MFCs

- Top 10 Mass Flow Controller for Gases 2025

- SI Series: Professional Grade Solutions

- Complete Comparison Table

- Industry Applications & Use Cases

- Installation & Calibration Guide

- Maintenance & Troubleshooting

- Future Trends in Gas Flow Control

- Frequently Asked Questions

- Technical References & Standards

- Professional Solutions Spotlight

💡 Quick Professional Insight

Selecting the right Mass Flow Controller for gases requires understanding accuracy requirements, flow range, gas compatibility, and control features. This guide provides comprehensive analysis to help you make informed decisions.

Typical Accuracy Range

High Precision

Turndown Ratio

Response Time

Gas Types Supported

How Mass Flow Controllers Work

Mass Flow Controllers for gases typically consist of three main components: a thermal mass flow sensor, a control valve, and an electronic control circuit. The sensor measures mass flow based on heat transfer principles, the control circuit compares the measured flow with the setpoint, and the control valve adjusts to maintain the desired flow rate.

Key Applications of Gas MFCs:

- Semiconductor Manufacturing: Precise gas delivery for deposition and etching processes

- Chemical Processing: Accurate reactant gas flow control

- Analytical Instruments: Carrier gas control in GC, MS, and FTIR

- Fuel Cell Research: Hydrogen and oxygen flow management

- Environmental Monitoring: Calibration gas flow control

- Pharmaceutical Production: Sterilization and process gas control

Key Selection Criteria for Gas MFCs

Accuracy Requirements

Consider ±0.5% F.S. for critical processes, ±1% F.S. for general applications, and ±2% F.S. for less critical uses.

Flow Range

Match your process requirements: 0-500 SCCM for laboratory use, 0-30 SLM for pilot plants, 0-3000 SLM for industrial processes.

Response Time

Fast response (200ms) for dynamic processes, standard response (1-2s) for steady-state applications.

| Selection Factor | Importance Level | Considerations | Recommended Specs |

|---|---|---|---|

| Accuracy | Critical | Process requirements, regulatory compliance | ±0.5-1% F.S. |

| Repeatability | High | Process consistency, quality control | ±0.2-0.5% F.S. |

| Rangeability | High | Process flexibility, future expansion | 50:1 to 100:1 turndown |

| Response Time | Medium-High | Process dynamics, control requirements | 200ms-2s |

| Gas Compatibility | Critical | Chemical resistance, safety considerations | Multiple gas calibration |

| Communication | Medium | Integration requirements, automation | RS-485, 4-20mA, PROFIBUS |

Top 10 Mass Flow Controller for Gases 2025

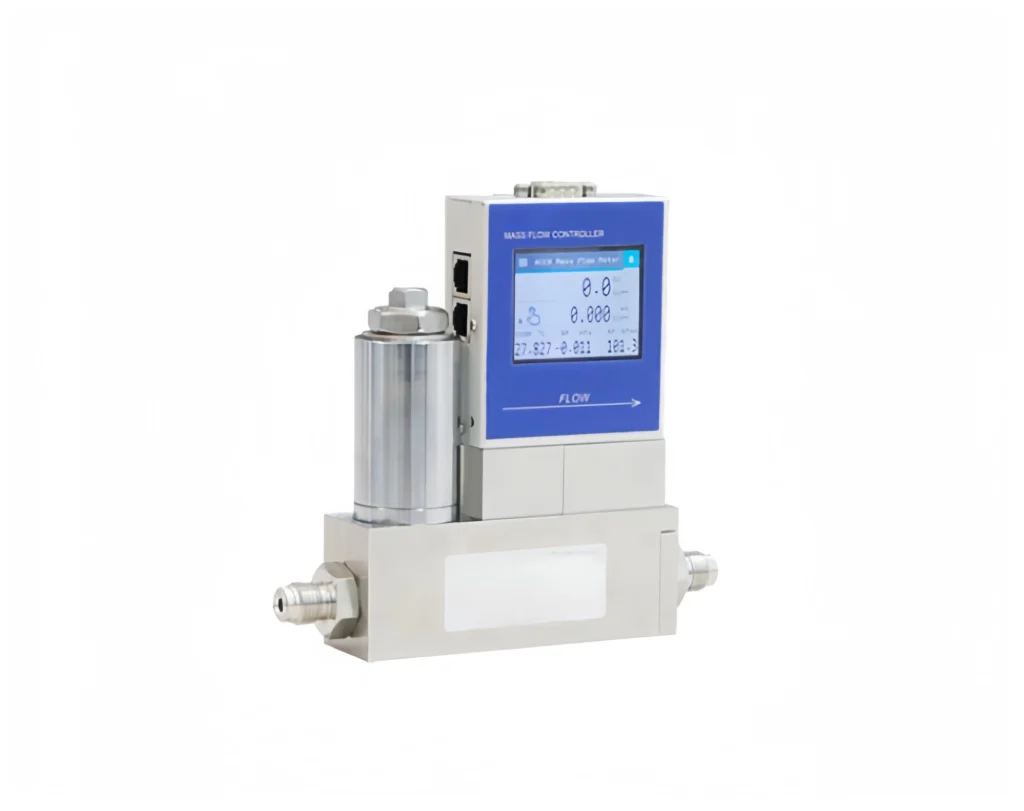

#1: SI-10FC Gas Mass Flow Controller 500SCCM

Accuracy

Excellent

Turndown Ratio

Response Time

Pre-set Gases

Key Features:

- No Thermal Drift: Negligible temperature drift and time drift with long-term stability of 0.1% F.S./year

- Wide Range Adjustability: 100:1 range adjustable via keypad without calibration

- Multi-Parameter Display: Simultaneous display of instantaneous and cumulative flow, pressure, and temperature

- Instant Operation: No warm-up required, zero response lag during measurement

- Built-in Gas Library: Conversion coefficients for 30 gases, eliminating specific heat capacity errors

- Multiple Communication: RS-485 / PROFIBUS digital output and 0-5 Vdc / 4-20 mA analog signals

Technical Specifications:

| Parameter | Flow Meter | Flow Controller |

|---|---|---|

| Measuring Range | 100SCCM~30SLM (Low) 30SLM~300SLM (Medium) 500SLM~3000SLM (Large) |

Same as Flow Meter |

| Accuracy | ±1% F.S (under standard conditions after zeroing) | |

| Repeatability | ±1% F.S | |

| Response Time | – | 200ms (adjustable) |

| Power Requirements | ±15VDC, 24VDC, 0.250 Amp | ±15VDC, 24VDC, 0.750 Amp |

| Operating Temperature | +10~ +50℃ | |

#2: SI-20FC High-Accuracy DP Mass Flow Controller

Accuracy

Premium

Repeatability

Response Time

Control Range

Premium Features:

- Ultra-High Accuracy: ±0.5% F.S. accuracy with ±0.2% F.S. repeatability

- Fast Response: Quick adjustment with response time <0.2s

- Touchscreen Interface: Modern display for easy operation

- Direct Mass Measurement: Differential pressure principle for true mass flow

- Integrated PID Control: Built-in PID controller for precise flow regulation

- No Thermal Effects: Negligible temperature drift and time drift

- Long-term Stability: 0.1% F.S./year stability guarantee

⚠️ Critical Application Note

The SI-20FC’s differential pressure measurement principle makes it ideal for applications requiring highest accuracy but may require more frequent calibration than thermal MFCs in certain conditions.

#3-10 Additional Top Picks for 2025

#3 Brooks Instrument SLA5850

Best for: High-purity semiconductor applications

Accuracy: ±0.6% F.S.

Range: 0-10 SLM

Semiconductor

High Purity

#4 Alicat Scientific MC Series

Best for: Multi-gas laboratory applications

Accuracy: ±0.4% F.S.

Range: 0-5000 SCCM

Laboratory

Research

#5 MKS Instruments 647B

Best for: Vacuum and deposition systems

Accuracy: ±0.5% F.S.

Range: 0-200 SCCM

Vacuum

Thin Film

#6 Bronkhorst F-201CV

Best for: Chemical process control

Accuracy: ±0.5% F.S.

Range: 0-100 SLM

Chemical

Process

#7 Sierra Instruments SmartTrak 100

Best for: Industrial process automation

Accuracy: ±1% F.S.

Range: 0-1000 SLM

Industrial

Automation

#8 Horiba Stec SEC-4000

Best for: Environmental monitoring

Accuracy: ±0.8% F.S.

Range: 0-50 SLM

Environmental

Monitoring

#9 Parker Veriflo P3MFC

Best for: OEM integration

Accuracy: ±1% F.S.

Range: 0-500 SLM

OEM

Integration

#10 Omega FMA5500

Best for: Budget-conscious applications

Accuracy: ±1.5% F.S.

Range: 0-100 SLM

Budget

General Purpose

SI Series: Professional Grade Solutions

SI-10FC vs SI-20FC: Choosing the Right Model

| Feature | SI-10FC | SI-20FC | Best For |

|---|---|---|---|

| Accuracy | ±1% F.S. | ±0.5% F.S. | SI-20FC for critical processes |

| Measurement Principle | Thermal Mass Flow | Differential Pressure | SI-10FC for general gas, SI-20FC for high accuracy |

| Response Time | 200ms | <200ms | SI-20FC for fast processes |

| Range Adjustability | 100:1 | 50:1 (control) 100:1 (measurement) |

SI-10FC for flexible range needs |

| Display | Monochrome LCD | Touchscreen LCD | SI-20FC for advanced interface |

| Gas Library | 30 pre-set gases | Custom calibration | SI-10FC for multi-gas use |

| Price Range | $$ | $$$ | SI-10FC for budget, SI-20FC for premium |

Complete Comparison Table

| Model | Accuracy | Flow Range | Response Time | Communication | Best Application | Price Category |

|---|---|---|---|---|---|---|

| SI-10FC | ±1% F.S. | 100SCCM-3000SLM | 200ms | RS-485, 4-20mA | General industrial | $$ |

| SI-20FC | ±0.5% F.S. | 2SCCM-3000SLM | <200ms | RS-232/485, 4-20mA | High precision | $$$ |

| Brooks SLA5850 | ±0.6% F.S. | 0-10 SLM | 1s | DeviceNet, 4-20mA | Semiconductor | $$$$ |

| Alicat MC Series | ±0.4% F.S. | 0-5000 SCCM | 100ms | USB, RS-232 | Laboratory | $$$ |

| MKS 647B | ±0.5% F.S. | 0-200 SCCM | 500ms | RS-232, 0-5V | Vacuum systems | $$$$ |

| Bronkhorst F-201CV | ±0.5% F.S. | 0-100 SLM | 300ms | PROFIBUS, 4-20mA | Chemical process | $$$ |

Industry Applications & Use Cases

Semiconductor Manufacturing

Requirements: Ultra-high purity, fast response, high accuracy

Recommended: SI-20FC, Brooks SLA5850

Typical Gases: SiH4, NH3, NF3, Ar

Analytical Instruments

Requirements: Stable flow, multi-gas capability, good repeatability

Recommended: SI-10FC, Alicat MC Series

Typical Gases: He, N2, H2, Air

Chemical Processing

Requirements: Corrosion resistance, wide flow range, robust construction

Recommended: SI-10FC, Bronkhorst F-201CV

Typical Gases: Cl2, HCl, SO2, CO

💡 Application-Specific Selection Tips

For semiconductor applications, prioritize accuracy and purity. For laboratory use, consider multi-gas capability and ease of calibration. For industrial processes, focus on robustness and maintenance requirements.

Installation & Calibration Guide

Mounting: Follow manufacturer orientation requirements

Piping: Use appropriate tubing size and material

Electrical: Connect power and signals per manual

Calibration: Perform zero and span calibration

⚠️ Critical Installation Notes

- Always install filters upstream to protect the MFC

- Follow specified orientation (vertical/horizontal) requirements

- Ensure proper grounding to prevent electrical noise

- Allow sufficient straight pipe runs before and after MFC

- Use appropriate leak detection methods after installation

Maintenance & Troubleshooting

| Maintenance Task | Frequency | Procedure | Tools Required |

|---|---|---|---|

| Zero Calibration | Monthly | With no flow, adjust zero to match actual zero | Calibration software |

| Span Calibration | Quarterly | With known flow, adjust span to match | Calibration standard |

| Filter Replacement | As needed | Replace inlet filters when pressure drop increases | Wrenches, new filters |

| Cleaning | Yearly | Clean with appropriate solvents for gas type | Cleaning kit |

| Performance Verification | Bi-annually | Check against reference standard | Reference MFC |

Future Trends in Gas Flow Control

IoT Integration

Remote monitoring and control via cloud platforms, predictive maintenance algorithms

AI Optimization

Machine learning for flow pattern recognition and automatic calibration adjustment

Miniaturization

Smaller footprint MFCs for portable and space-constrained applications

Multi-parameter Sensing

Integrated pressure, temperature, and humidity sensors in single units

Frequently Asked Questions

What’s the difference between a mass flow meter and a mass flow controller?

A mass flow meter only measures flow rate, while a Mass Flow Controller for gases both measures and controls flow rate using a control valve to maintain a setpoint.

How often should I calibrate my MFC?

For critical applications, calibrate every 3-6 months. For general industrial use, annual calibration is typically sufficient. Always follow manufacturer recommendations and consider process requirements.

Can one MFC handle multiple gases?

Many modern MFCs like the SI-10FC have built-in conversion coefficients for multiple gases. However, accuracy may vary, and some gases may require specific calibration.

What is turndown ratio and why is it important?

Turndown ratio (e.g., 100:1) indicates the range over which the MFC maintains specified accuracy. Higher turndown ratios provide greater flexibility for varying process conditions.

How do I choose between thermal and differential pressure MFCs?

Thermal MFCs (like SI-10FC) are generally better for clean, dry gases. Differential pressure MFCs (like SI-20FC) offer higher accuracy and can handle some dirty or wet gas applications better.

What communication protocols are most common?

RS-485 and 4-20mA analog signals are industry standards. Some advanced models offer PROFIBUS, DeviceNet, or Ethernet/IP for industrial automation integration.

Professional Solutions Spotlight

Why SI Series Stand Out for Gas Flow Control

Long-term Stability

Pre-configured

Instant Operation

Range Adjustability

SI-10FC vs SI-20FC: Professional Application Guide

| Application Scenario | Recommended Model | Key Features Utilized | Expected Performance |

|---|---|---|---|

| Laboratory Gas Chromatography | SI-10FC | Multi-gas capability, no warm-up | ±1% accuracy, immediate readiness |

| Semiconductor Etch Process | SI-20FC | ±0.5% accuracy, fast response | High precision, minimal overshoot |

| Chemical Reactor Feed | SI-10FC | Wide range adjustability, robust construction | Reliable operation, easy range changes |

| Fuel Cell Research | SI-20FC | High accuracy, touchscreen interface | Precise stoichiometric control |

| Environmental Monitoring | SI-10FC | Built-in gas library, low power | Multi-gas capability, field deployment |

🏆 Final Professional Recommendation

For most industrial applications requiring a reliable Mass Flow Controller for gases, the SI-10FC offers exceptional value with its combination of accuracy, flexibility, and ease of use. For critical processes where every percentage point matters, the SI-20FC provides professional-grade precision and control capabilities.

⚠️ IMPORTANT CONSIDERATIONS

Always verify gas compatibility, pressure ratings, and environmental conditions before selecting any Mass Flow Controller for gases. Consider future expansion needs and ensure proper installation and maintenance for optimal performance and longevity.

.png)