The KPT-561FW sensor is made to measure pH levels online for a long time under hostile water circumstances. It has a body made of PVDF that won’t rust, a PTFE ring junction that won’t get dirty, and a solid gel electrolyte that makes maintenance easier. The gel salt bridge helps protect the electrodes from being poisoned (for example, by S²⁻ or CN⁻), which makes it work quickly and reliably for industrial uses.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| Measurement Range | 0-14 pH |

| Theoretical percentage slope | ≥95% |

| Zero potential | 7±0.5 |

| Temperature Range | 0-130℃ |

| Pressure Range | 0-0.3 M Pa |

| Body Material | PVDF |

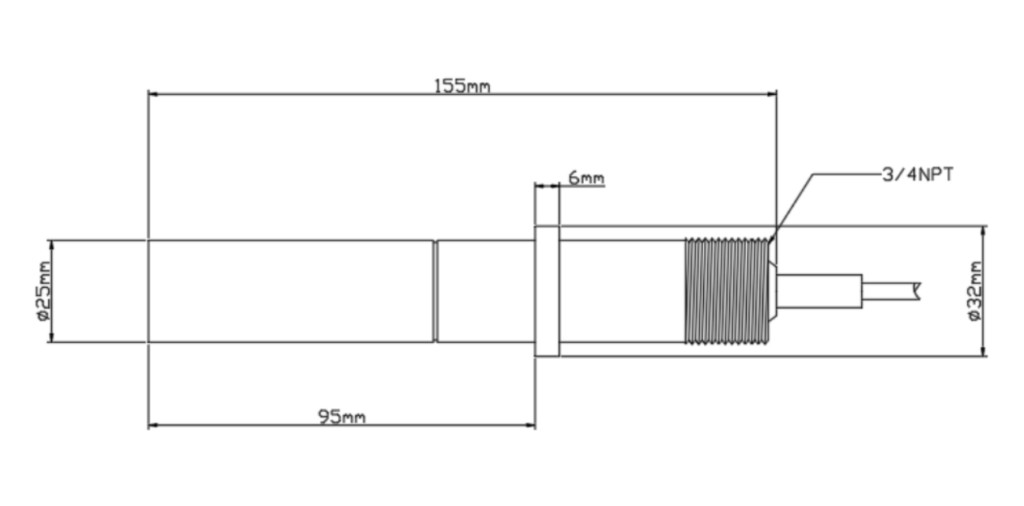

| Thread Size | 3/4 inch NPT |

| Junction / Electrolyte | PTFE ring junction + solid gel electrolyte |

Scope of Application

- The sensor can be used in conjunction with various acidity meters and is suitable for online detection of pure water;

- If the sensor is used normally for six months, its lifespan may be shortened due to harsh environments or improper maintenance.

Typical Applications

- Industrial wastewater online monitoring (recommended use case).

- Neutralization tanks / equalization tanks

- Effluent discharge monitoring

- Chemical dosing control loops

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode.

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles.

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes.

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

Installation & Wiring Notes

Before installation

- After opening the package, check whether the glass bulb and electrode body are mechanically damaged.

- Remove the protective cap; if bubbles exist in the sensitive bulb area, gently swing the electrode vertically to remove bubbles.

- Choose the proper protective sheath / cable gland based on the installation method.

- The cable-to-electrode connection is not waterproof—make sure waterproofing is done onsite.

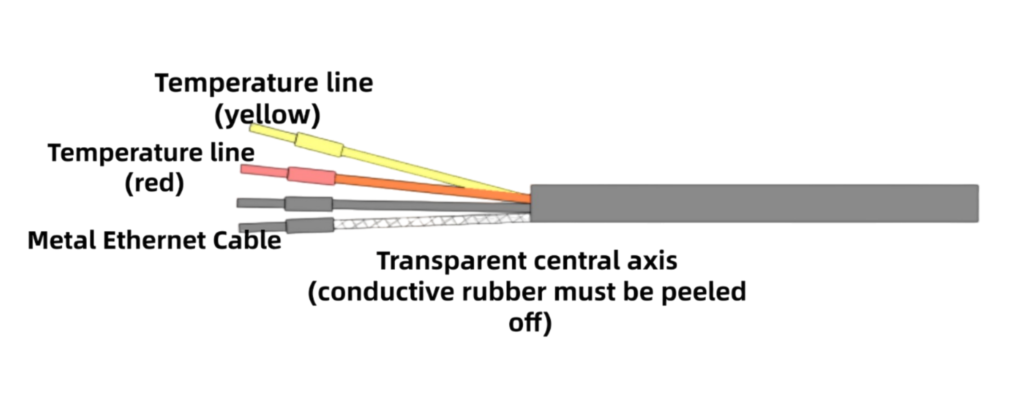

Stripping / wiring caution (important)

- When stripping the cable, separate the metal mesh layer as required, and remove the conductive black layer on the transparent center core.

- From electrode to host, no intermediate joints are allowed (except a dedicated junction box).

Maintenance & Care

- Rinse with distilled/deionized water and blot dry with filter paper before measurement to avoid contaminating the sample; ensure bulb and junction are immersed.

- When not in use, rinse and cover with protective cap containing 3.3 mol/L KCl soaking solution.

- For wastewater pH electrodes, avoid long-term soaking in distilled water, protein solutions, or acidic chloride solutions; avoid contact with silicone grease.

- If the glass membrane becomes translucent or has deposits, wash with dilute hydrochloric acid then rinse with water.

- Recommended: clean weekly and calibrate with the instrument.

- If it still can’t be calibrated after maintenance, the electrode may be unrecoverable—replace it.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The KPT561FW isn’t simply another tool to add to your setup; it’s an update you can experience every day. It combines dependability, useful performance, and a design that is easy to use and makes life easier. The KPT561FW performs the way it should, whether you want to make your work flow more smoothly, get more done every day, or just want something that functions the way it should. If you’re not sure, this is one of those decisions that pays off right away.

Request a Quote

.png)