GRT1020C industrial pH electrode is designed for pure water and complicated sewage. Traditional electrodes are easy to block, “poisoned” and difficult to maintain. The antifouling ring polytetrafluoroethylene liquid interface and gel dielectric salt bridge overcome these issues. Whether for high-purity water detection or long-term monitoring of toxic ions like S ² ⁻ and CN ⁻, this device consistently outputs data with low internal resistance and fast response, reducing operation and maintenance costs.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-100℃ |

| Pressure Range | 0-0.3 M Pa |

| Theoretical percentage slope (%) | ≥ 95 |

| Zero Potential | 7±0.5 |

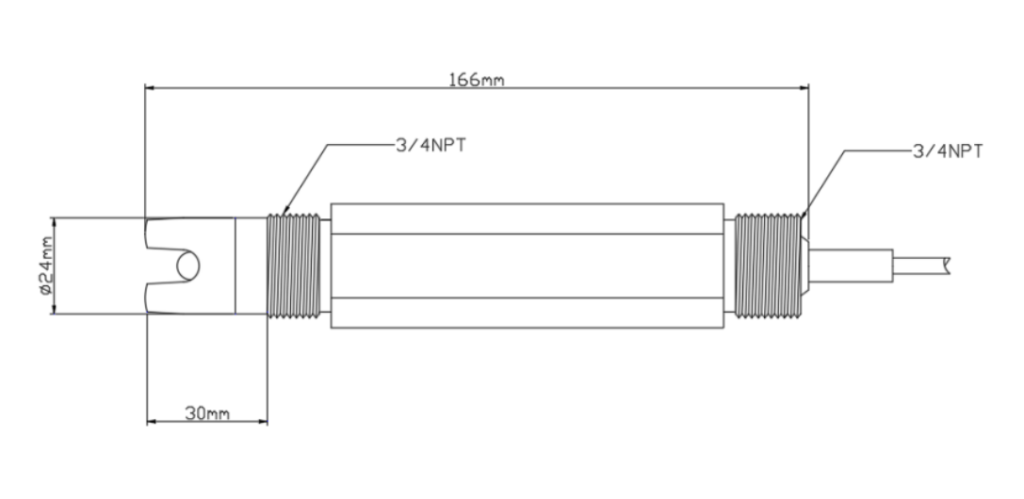

| Thread Size | 3/4 inch NPT |

Scope of Application

- The electrode can be used in conjunction with various acidity meters and is suitable for online detection of sewage;

- If the electrode is used normally for six months, its lifespan may be shortened due to harsh environments or improper maintenance.

Core performance advantages

- Anti pollution and anti blockage, long-term online: using a circular polytetrafluoroethylene liquid interface to increase the contact area with the water sample while effectively reducing the adhesion and blockage of suspended solids, suitable for long-term online monitoring of sewage, without the need for frequent disassembly and cleaning.

- Anti poisoning design and life guarantee: gel dielectric salt bridge can accurately block the corrosion of toxic ions such as S ² ⁻ and CN ⁻ on the reference electrode, to avoid electrode “poisoning” failure, and its life can reach half a year in normal use.

- Convenient operation and small maintenance: solid gel dielectric is used, without additional dielectric supplement; Only one regular cleaning and calibration is required per week, making it easy for beginners to operate.

- Full scene adaptation, precise measurement: Special glass sensitive film covers various pH measurement conditions, with low electrode resistance, fast response speed and good stability, and data accuracy meets environmental protection and process monitoring standards.

- Standardized installation, strong adaptability: equipped with 3/4 inch NPT standard thread and terminal blocks, it can directly adapt to existing pipelines, immersion brackets and other installation scenarios without additional modification.

- Wide compatibility and flexible matching: It can be used in conjunction with various acidity meters on the market without worrying about device compatibility issues, reducing replacement costs.

Exclusive adaptation scenario

Online discovery of pure water

Keeping a close eye on the pH level is very important to make sure that the water quality meets the standards for making pure water in businesses like electronics and medicines. The GRT1020C can catch small changes in the pH of pure water right away because of its low internal resistance and quick reaction time. This gives useful information for water quality control.

Industrial wastewater monitoring

Electrode designs that are resistant to both poisoning and pollution can prevent frequent failures and fulfill the continuous monitoring requirements of sewage treatment plants, which are 24 hours per day. This is particularly relevant in the case of municipal wastewater that has a high concentration of suspended particles as well as chemical wastewater that contains S ² ⁻ and CN ⁻.

Conventional water quality monitoring scenarios

In the monitoring of production wastewater in industries such as food processing and electroplating, its convenient maintenance characteristics and wide compatibility can reduce the workload of operation and maintenance personnel and adapt to diverse production environments.

Usage and Maintenance Guide

Pre installation inspection and operation

- Once the box has been opened, the initial step is to examine whether or not there has been any mechanical damage to the delicate bulb and electrode body. If there is any damage, it cannot be utilized.

- If there are any bubbles detected within the sensitive bulb after the protective cover has been removed, carefully shake the electrode in a vertical plane to ensure that all of the bubbles have been eliminated and to prevent any potential impact on the precision of the measurement.

- The electrode type must be taken into account when selecting the appropriate protective sleeves or cable connectors for installation. This will guarantee that there is a secure attachment and that there will be no shaking when the device is being used.

Key points for cleaning and maintenance

- Before measurement, the electrode should be washed with distilled water or deionized water, and the surface moisture should be absorbed by filter paper to avoid impurities contaminating the measured water sample; Ensure that the bubble and liquid interface are submerged simultaneously during measurement.

- When the electrode is not in use, it should be cleaned and covered with a protective cover soaked in 3.3Mol/L KCL solution. It is strictly prohibited to leave it dry, otherwise it will quickly shorten its lifespan.

- Avoid prolonged immersion in distilled water, protein solutions, and acidic chloride solutions, while also preventing contact with organic silicone oils, as these substances can damage sensitive membranes.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

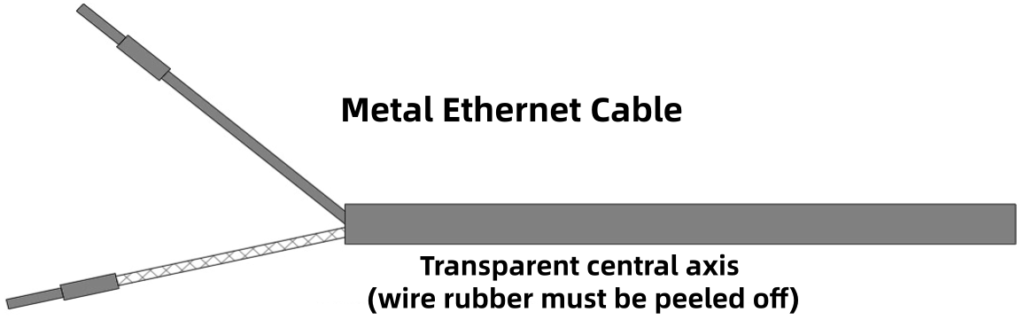

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

Many teams who monitor water quality have problems with frequent breakdowns, difficult maintenance, and wrong data. GRT1020C fixes these problems. The antifouling fluid connection inhibits particles that are floating about, the gel salt bridge keeps dangerous ions apart, and the compensation-free dielectric design lowers the pressure on the roots during operation and maintenance. It can correctly manage clean water or confirm that wastewater meets standards for six months with weekly maintenance. For checking the quality of water, you may trust GRT1020C.

Request a Quote

.png)