Industrial pH electrode GRT1020D is designed for difficult water quality scenarios including environmental and industrial wastewater. Circular polytetrafluoroethylene liquid interface and double salt bridge reference structure provide anti-pollution, anti-blocking, anti-ion poisoning, and electrolyte-free benefits. It measures pH 0-14 and has a six-month service life. It is a cost-effective online pH monitor for municipal sewage plants, chemical parks, and other applications.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.4 M Pa |

| Theoretical percentage slope (%) | ≥ 95 |

| Zero Potential | 7±0.5 |

| Internal Resistance | 25℃ ≤ 250 MΩ |

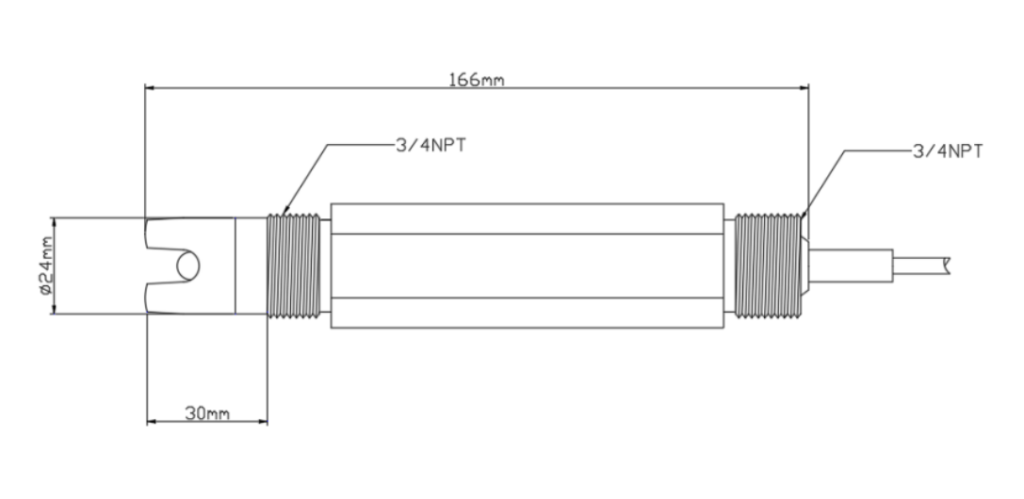

| Thread Size | 3/4 inch NPT |

Scope of Application

- The sensor can be used in conjunction with various acidity meters and is suitable for online detection of sewage;

- If the sensor is used normally for six months, its lifespan may be shortened due to harsh environments or improper maintenance.

Core strength

Circular anti clogging “filter screen”

Traditional electrode-liquid interfaces choke suspended particles. The circular PTFE liquid interface of GRT1020D doubles contact area, making wastewater sediment and flocculent chemicals difficult to stop. After evaluating the environmental wastewater treatment facility, the cleaning cycle was extended from 3 to 7 days, doubling operating and maintenance efficiency.

Double Salt Bridge “Anti toxic Shield”

For toxic ions such as S ² ⁻ and CN ⁻, the ordinary sensor’s single salt bridge can be easily punctured, while its double salt bridge design is equivalent to a “double defense line”, intercepting toxic ions outside the reference system. It will not be “poisoned” after six months of normal use, and the replacement cost will be reduced by 80%.

No need to supplement the “worry free chip”

Built in solid gel dielectric, completely say goodbye to the trouble of replenishing KCL solution every day. Even beginners in operations can easily handle it, with regular cleaning once a week, eliminating the need for midnight emergencies and truly freeing up manpower.

Scenario based applications:

Municipal sewage treatment plant

Pain points: There are many suspended solids in the aeration tank, frequent electrode blockages, and maintenance personnel soak in the sewage room every day.

Performance: The circular liquid interface is matched with 3/4 inch NPT standard thread, which can be directly screwed onto the existing pipeline without dismantling or washing for 7 days. The data is stable and uploaded to the environmental protection platform, and there is no need to manually monitor calibration.

Toxic wastewater in chemical industrial parks

Pain points: Electroplating and coking wastewater contains high concentrations of S ² ⁻, ordinary sensorss are scrapped in one month, and data interruption faces environmental fines.

Performance: Double salt bridge+gel salt bridge double protection, no “strike” in 6 months of continuous monitoring, theoretical percentage slope ≥ 95%, data accuracy fully meets the pollution discharge standard.

Universal Water Quality Monitoring

Advantages: The special glass sensitive film is compatible with a full pH range of 0-14 and can be used with all acidity meters on the market. It can hold scenarios such as food processing and pharmaceutical wastewater, and the wiring terminal design can be installed and replaced in just 10 minutes.

Electrode Installation and Maintenance Guide

Installation three-step process (key to avoiding pitfalls)

- Open box inspection: Confirm that there is no mechanical damage to the sensitive bulb and sensor body, and that there are no bubbles inside the bulb (any bubbles can be removed by gently shaking vertically)

- Waterproof treatment: The sensor wire connection is not waterproof and needs to be wrapped with waterproof tape or equipped with waterproof joints

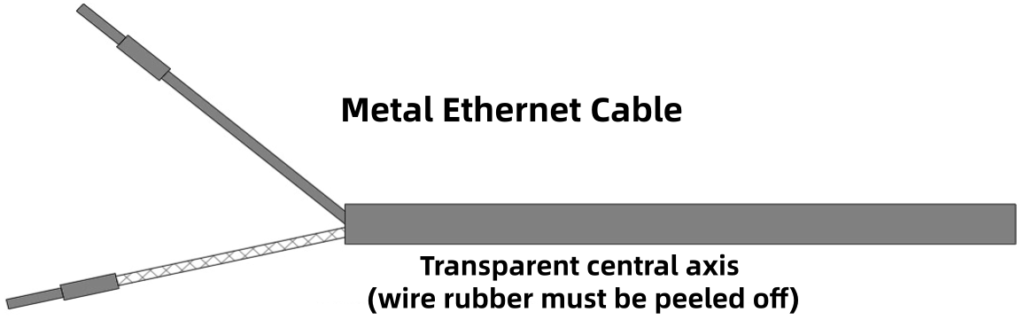

- Standardized wiring: After peeling off the metal wire layer, completely remove the transparent central axis conductive black skin, and there are no additional contacts in the middle of the cable

Key points of daily maintenance

- Wash the electrode with distilled water before measurement, and absorb the moisture with filter paper (do not wipe sensitive bubbles)

- When idle, put in a protective cover containing 3.3Mol/L KCL soaking solution and strictly prohibit dry storage

- When the glass film adheres to sediment, soak it in 5% -10% dilute hydrochloric acid for 1 minute and rinse it. Calibrate once a week

Common Problems and Solutions

| Possible | Causes | Solutions |

| Measurement drift | Electrode aging and pollution | Clean, recalibrate or replace electrodes |

| Slow response | Fluid interface blockage, glass film damage | Rinse with hot water or dilute acid to check if the membrane is intact |

| The reading is unstable | Insufficient reference electrolyte and interference signal | Supplement electrolyte and check cable connections |

| Calibration failed | Buffer contamination, electrode damage | Replace with fresh buffer solution and test electrode performance |

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

Are you still adding costs for frequent electrode replacement and repeated maintenance and debugging? The GRT1020D pH electrode, with its dual salt bridge anti-virus, circular anti blocking, and electrolyte free hard core strength, can not only help you maintain the precise bottom line of environmental monitoring data, but also help you save operation and maintenance expenses. Make GRT1020D your “stable revenue partner” in the sewage monitoring process!

Request a Quote

.png)