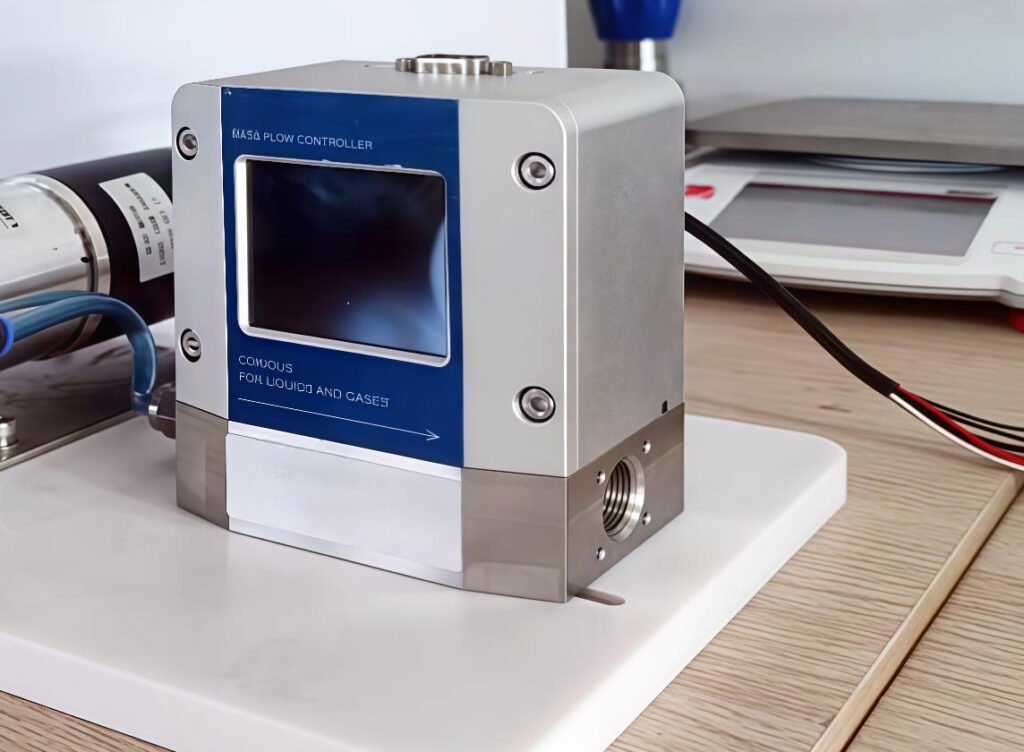

The SI-30FC is a high-precision DP Mass Flow Controller for Gases series. It features a compact design with a large screen for enhanced convenience and user-friendliness. This series utilizes a differential pressure mass measurement principle with no thermal drift and no response hysteresis. It can simultaneously display and output instantaneous flow rate, cumulative flow rate, pressure, temperature, etc.

★★★★★

Features

Specifications

| Technical Specifications | High-Precision Mass Flow Controller | High-Precision Mass Flow Meter |

| Measurement Range | 2SCCM ~ 300SLM | |

| Control Range | Valve Control Range 50:1 | Flow rate range ratio 100:1 |

| Accuracy | ±0.5% F.S. (Full Scale) | |

| Linearity | ±0.5% F.S. | |

| Repeatability | ±0.2% F.S. | |

| Stability | <±0.1% F.S. | |

| Response Time | 50mS | |

| Temperature Coefficient | ±0.015% F.S./℃ | |

| Operating Temperature | -10°C ~ 60°C | |

| Operating Pressure | Operating Differential Pressure: 0.05~0.5MPa | |

| Maximum Pressure Rating | 1MPa | |

| Leak Rate | 1×10⁻⁹ Pa·m³/s | |

| Base Material | Stainless Steel | |

| Connection | VCR, Ferrule, Quick Connect, Tower, Flange Mounting | |

| Seal Material | Fluoroelastomer, Nitrile Rubber, Perfluoroether, EPDM | |

| Enclosure Protection Rating | IP40 | |

| Mounting Position | Horizontal installation | |

| Monochrome LED Display | Simultaneous display of flow and setpoint | |

| Electrical Connection | DB9 port, RJ11, 5.5×2.1 quick-connect power connector | |

| Display Status | With LCD display, without LCD display | |

| Digital Inputs | Modbus protocol (RS232/485), ProfiBus protocol, DeviceNet protocol | |

| Analog Inputs | 0 ~ 5V, 4-20mA, 1-5V | |

| Power Supply | ±15VDC, 24VDC | |

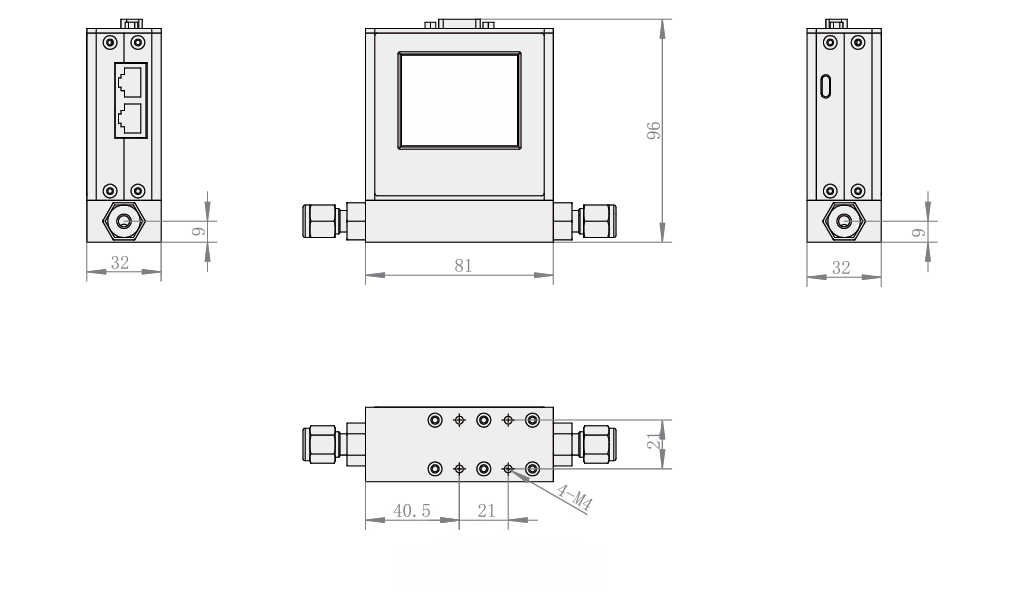

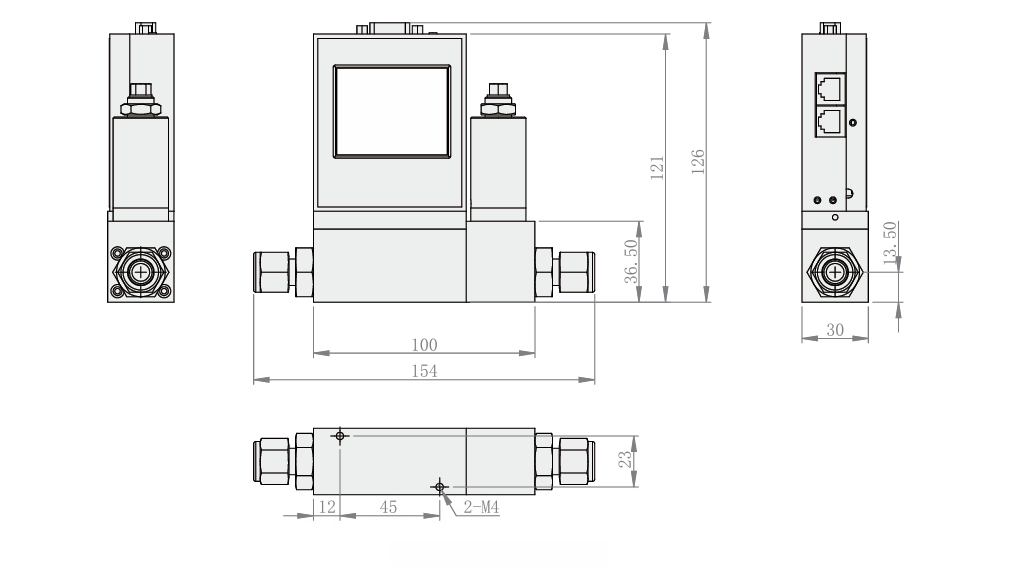

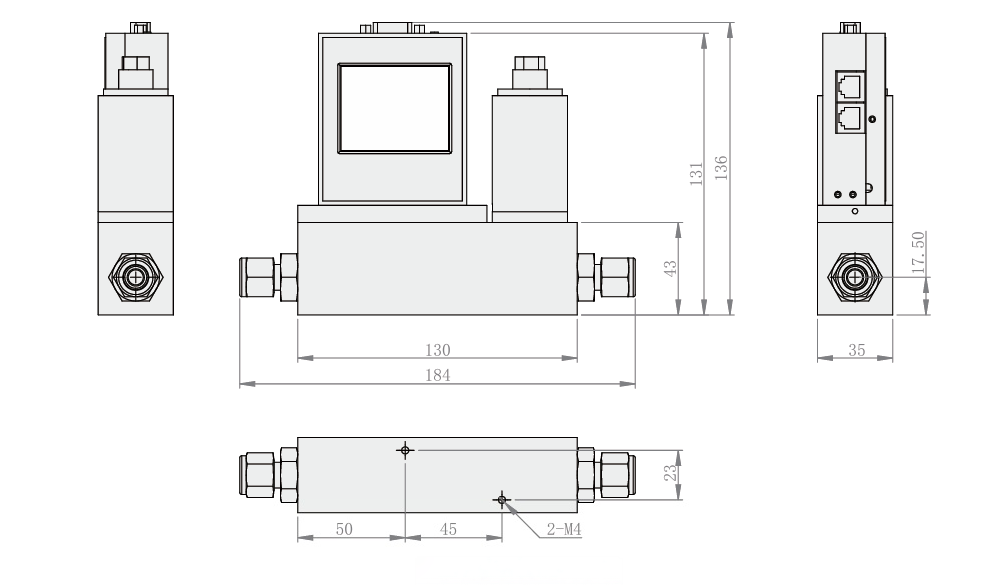

| Model | SI-30FC-S | SI-30FC-L | SI-30FC-MC |

| Measurement Range | 2SCCM~30SLM | 2SCCM~30SLM | 30SLM~300SLM |

Performance and Principle

The SI-30FC series flow meter uses the differential pressure principle, calculating flow rate based on the pressure difference generated when fluid passes through a throttling element. The product incorporates a built-in PID control function, working in conjunction with an electromagnetic proportional control valve to achieve precise flow control.

When fluid flows from a pipe through the throttling element, the flow velocity increases and the static pressure decreases, creating a differential pressure across the element. A sensor measures this differential pressure, converting the signal into an electrical signal and outputting it. The controller uses the flow equation (Hagen-Poiseuille formula) to calculate the fluid flow rate.

The SI-30FC can measure multiple parameters such as mass flow rate, volumetric flow rate, pressure, and temperature of gases. These parameters can be displayed on a touchscreen or other external devices and control systems via RS485/232 communication methods for data monitoring and analysis.

Factors Affecting the Accuracy of Mass Flow Controllers/Meters for Gases

In our communication with customers, we often receive feedback like this: when testing flow meters from different brands in series, discrepancies are found in their readings. Does this mean that one of the flow meters is inaccurate? The answer is not so simple. As precision measuring devices, differences in flow meter readings are often caused by a combination of factors.

Common Reasons for Differences in Flow Meter-Flow Controller Readings:

- Accumulated Errors from the Flow Meter Itself

Comparing two flow meters, both with an accuracy of 1% F.S., in series can result in a difference of nearly 2% F.S. in the worst-case scenario, leading to the misconception that one of the meters is out of tolerance.

- Inconsistent Gas Types

If air is introduced during testing, but the two flow meters are not both testing air, the readings will differ.

- Inconsistent Standard Condition Definitions

Comparing the standard condition flow rate (mass flow rate) of two flow meters requires that the standard condition definitions are the same. Standard condition pressure is typically 101.325 kPaA, and standard condition temperatures include 0℃, 15℃, 20℃, and 25℃. Before testing, ensure that the standard condition temperatures are identical, not just the actual temperatures. Sino-Inst flow meters can switch between these four standard condition temperatures.

- Significant Differences in Flow Range

Comparing the accuracy of a 100 SLPM flow meter with a 1 SLPM flow meter is meaningless, as flow meters often have poor accuracy in the lower flow range. A flow meter with a 100 SLPM range (assuming an accuracy of 1% F.S.) may still have an error of 1 SLPM when measuring a flow rate of 1 SLPM.

- Temperature and Pressure Differences

If one flow meter operates at high pressure and the other at normal pressure, pressure drift will be introduced. Similarly, different temperatures will introduce temperature drift.

- Pipeline Connection Issues

Air leaks in the pipeline or loose connections will cause the actual flow rates of the two flow meters to differ. When the flow meter range is small and the intermediate pipeline is long and thick, the volumetric effect is significant, and the readings of the two flow meters will also be inconsistent. If the outlet of one flow controller is closely connected to another flow meter, it will also affect the accuracy of the other flow meter.

- Misunderstandings Caused by Different Measurement Principles

For example, laminar flow differential pressure flow meters and thermal flow meters differ significantly in response speed (measurement sensitivity) and gas switching principles, which can easily lead testers to use incorrect testing methods. For example, when the gas source pressure fluctuates, the laminar flow pressure difference principle responds very quickly, causing the measured value to appear to fluctuate as well, while the thermal flow meter’s measured value will appear relatively stable. Another common misconception is that if two nitrogen flow meters based on different principles are both circulated with air and compared, the results obtained after conversion using their respective conversion methods are likely to be inconsistent.

- Different Traceability Standards

Flow meters require traceability to pass on standards, and the traceability standards for flow meters from different manufacturers differ. Sino-Inst flow meters are traceable to the National Institute of Metrology of China. Even if two flow meters are within their nominal accuracy range, their readings may still differ.

Besides the above reasons, the flow meter’s zero drift, the sensor’s accuracy, and stability will also affect the measured value.

Technical Support

How Does a thermal mass flow controller working principle?

8 Best Mass Flow Controller Manufacturers

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

Guide to Connecting a Thermal Mass Flow Controller to a PLC

The laminar flow DP Mass Flow Controller/Meter, as a high-precision flow measurement device, is widely used in chemical, pharmaceutical, and aerospace industries due to its simple structure and high stability. Its core value lies in its ability to directly measure mass flow rate without additional temperature and pressure compensation, solving the measurement deviation problem of traditional volumetric flow meters under complex operating conditions.

Sino-Inst supports parameter customization for the Mass Flow Controller for Gases. Please contact our sales engineers at any time!

Request a Quote

Related Products

SI-30FC Compact DP Mass Flow Controller for Gases

The SI-30FC is a high-precision DP Mass Flow Controller for Gases series. It features a compact design with a large screen for enhanced convenience and user-friendliness. This series utilizes a differential pressure mass measurement principle with no thermal drift and no response hysteresis. It can simultaneously display and output instantaneous flow rate, cumulative flow rate, pressure, temperature, etc.

Product SKU: SI-30FC Compact DP Mass Flow Controller for Gases

Product Brand: Sino-Inst

Price Valid Until: 2099-09-09

Product In-Stock: PreOrder

5

.png)