The SI-20FDR gas mass flow controller is a high-precision gas flow measurement and control device. It achieves an accuracy of ±0.5% of full scale and is suitable for controlling mass flow even with virtually no available system pressure.

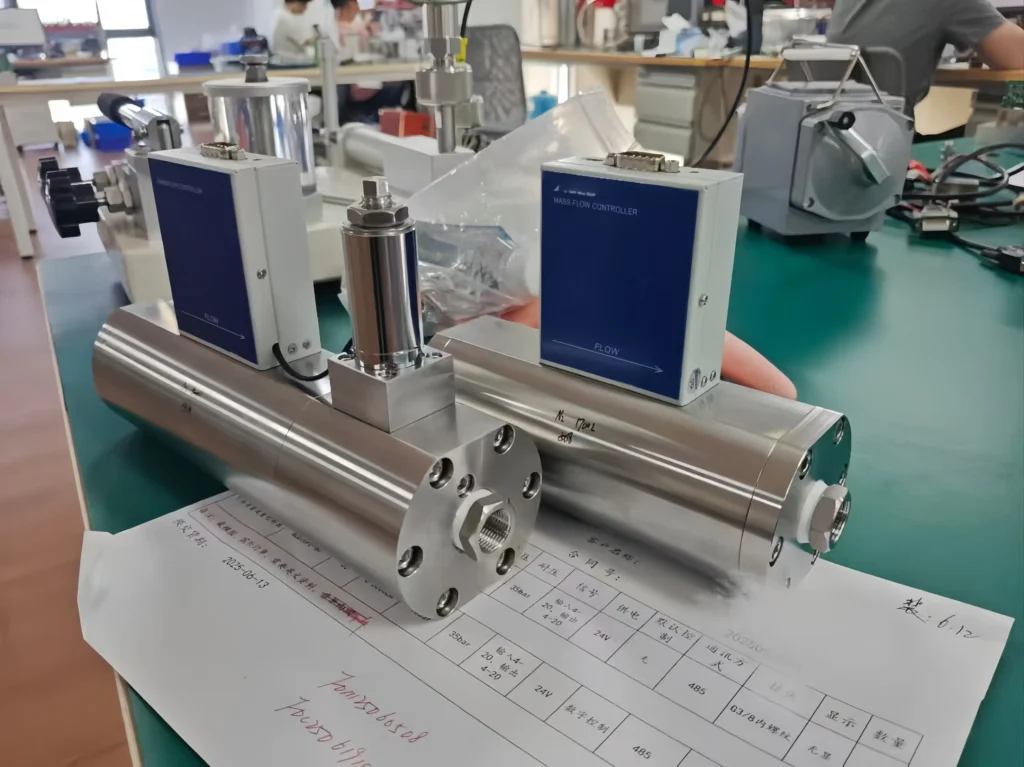

The SI-20FDR series features two independently controllable valves connected in series: a main valve and a fine-tuning valve. A sophisticated control algorithm coordinates the opening and closing of these two valves, enabling rapid, stable, and high-precision control of gas flow.

★★★★★

Features

Specifications

| Series | SI-20FDR | |||||||

| Model | LC | LM | MC | MM | BC | BM | HC | HM |

| Range | 0-(150,200,300…600)SLM | 0-(600,700…1200)SLM | 0-(1200,1500…4000)SLM | 0-(4000,4200…6000)SLM | ||||

| Accuracy | ±0.5%F.S | |||||||

| Linearity | ±0.5%F.S | |||||||

| Repeatability | ±0.2%F.S | |||||||

| Operating Differential Pressure | 0.3~0.5MPa (Specified when ordering) | |||||||

| Response Time | <0.2s | <0.1s | <0.2s | <0.1s | <0.2s | <0.1s | <0.2s | <0.1s |

| Turndown Ratio | 50:1 | 100:1 | 50:1 | 100:1 | 50:1 | 100:1 | 50:1 | 100:1 |

| Response Time | <0.8s | |||||||

| Warm-up Time | < 5s | |||||||

| Analog Output | 0~5V、4~20mA | |||||||

| Digital Output | RS232/485, MODBUS protocol | |||||||

| Power Supply | 24VDC | |||||||

| Communication Protocol | Modbus、DeviceNet、profinet、ErtherCAT、profibus | |||||||

| Operating Temperature | 0~50℃ | |||||||

| Maximum Pressure Rating | 3MPa/10MPa (Specified when ordering) | |||||||

| Electrical Connection | DB9 port | |||||||

| Monochrome LCD Display | Simultaneously displays flow rate and settings | |||||||

| Maximum Pressure Rating | 3MPa/10MPa | |||||||

| Leak Rate | 1×10-9Pa m³/S | |||||||

| Protection Rating | IP40 | |||||||

| Base Material | Stainless steel | |||||||

| Seal Material | fluororubber, nitrile rubber, EPDM, perfluoroether | |||||||

| Case Thread | G3/4 internal thread | 1 inch | ||||||

| Connection | Ferrule fittings, pagoda fittings, quick-connect fittings, VCR fittings, flanges, etc. | |||||||

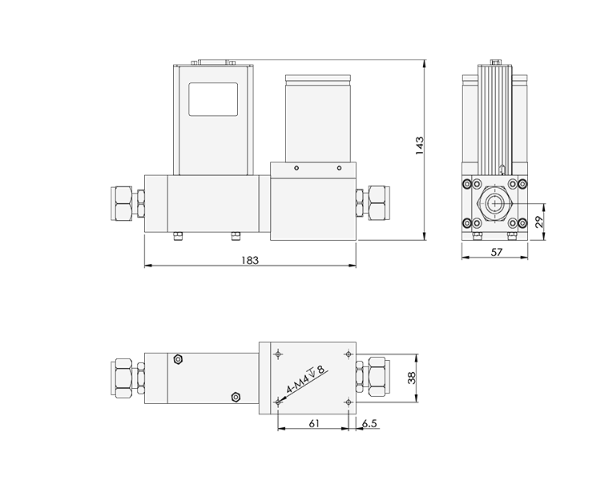

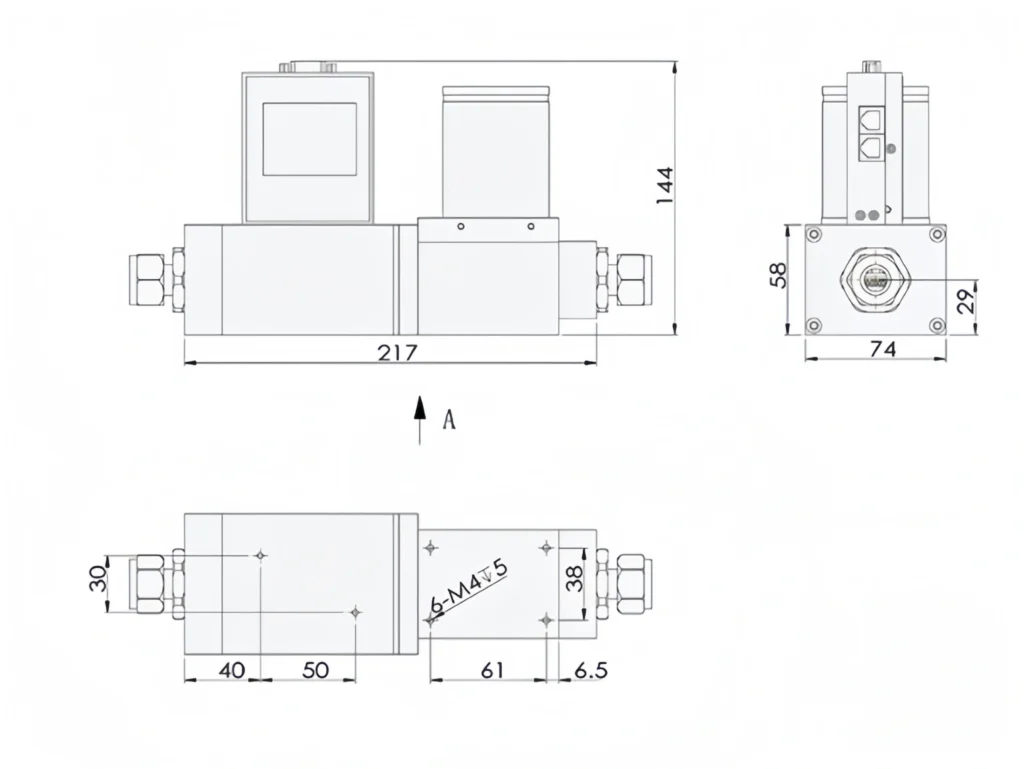

SI-20FDR-LC Dimension

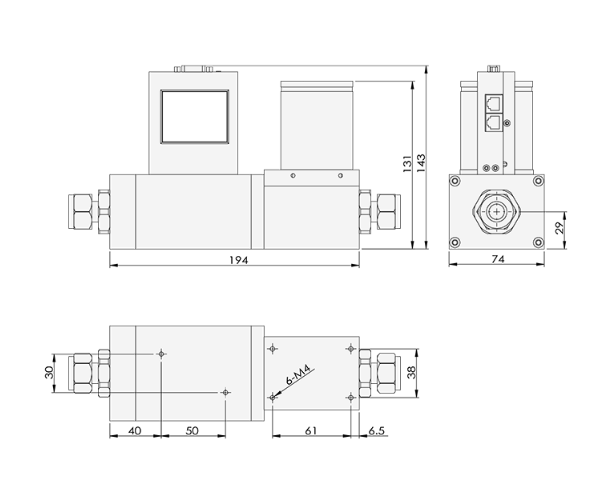

SI-20FDR-LC Dimension SI-20FDR-MC Dimension

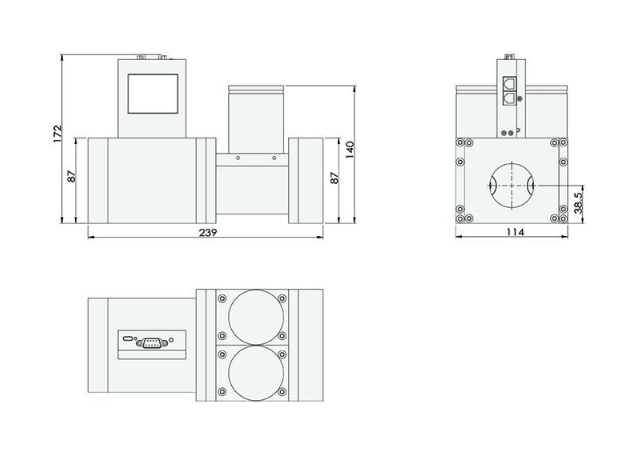

SI-20FDR-MC Dimension SI-20FDR-HC Dimension

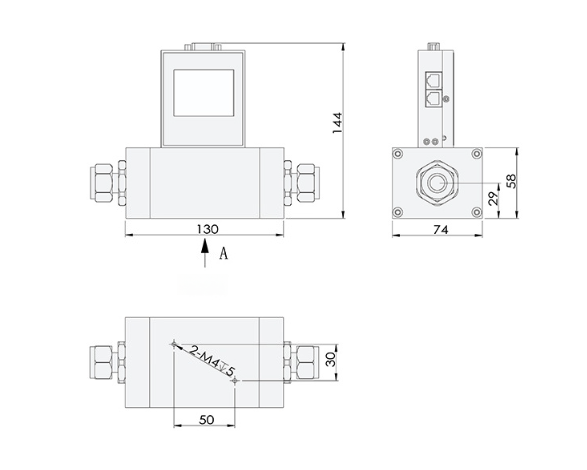

SI-20FDR-HC Dimension SI-20FDR-BM Dimension

SI-20FDR-BM Dimension SI-20FDR-BC Dimension

SI-20FDR-BC Dimension

Gas Mass Flow Controller Working Principle

The SI-20FDR is a high-accuracy flowmeter/controller series with a measurement error of only ±0.5% of full scale. The series’s exceptional precision stems from its unique sensor probe, a sealed unit comprising two sensing elements—a velocity sensor and a temperature sensor—that automatically correct for the effects of temperature and pressure variations.

The instrument circuit heats the velocity sensor to a constant value above the gas/liquid temperature, then measures the cooling effect of the gas flow. Flow is calculated based on the principle that the electrical power consumed to maintain a constant temperature difference is proportional to the gas mass flow rate. Both sensors are standard-grade platinum resistance temperature detectors (RTDs), sealed within a stainless steel housing.

Gas Mass Flow Controller Application – Gas Mixing

A suitable gas source, a precise mass flow controller, and a pressure gauge can create a fast gas mixing system. Many applications choose to mix gases on-site because purchasing custom-mixed gases from gas suppliers is quite expensive. Purchasing only pure gases not only reduces costs but also allows users to adjust the composition percentages of the constituent gases according to application requirements, greatly increasing convenience. Furthermore, for safety reasons, custom-mixed gases are transported and stored in steel cylinders, which cannot be disposed of casually after use and sometimes must be returned to the gas supplier according to regulations. Using various pure gases for mixing is much more convenient.

Using a Sino-Inst mass flow controller to control the flow rate of each pure gas source individually allows for rapid gas mixing and control of the synthesis percentage.

In dynamic systems, the mixing ratio of the gas mixture may not always be 75% gas A + 25% gas B. What if this mixing ratio is used today, then changed to 25% gas A + 75% gas B tomorrow, and then changed to 50% gas A + 50% gas B later? Carefully considering the gas mixing ratios that may be used in the future to determine the flow range is crucial when purchasing a mass flow controller for gas mixing projects.

Our Sino-Inst mass flow controller is preset with 98 to 128 commonly used gases, allowing users to switch on-site at any time. This eliminates the need to purchase multiple mass flow controllers that are limited to a single gas, greatly saving on your purchase costs.

Technical Support

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

CO2 Sensor vs. VOC Sensor: What’s the Difference?

The SI-20FDR gas mass flow controller is a high-precision gas flow measurement and control device. Accuracy reaches ±0.5% of full scale. It is widely used in projects requiring precise flow control, such as those involving air, hydrogen, and nitrogen.

Equipped with a proprietary high-flow-capacity solenoid valve, it is suitable for controlling mass flow even with virtually no available system pressure. Low pressure differential ensures minimal impact on the system, achieving flow control near atmospheric pressure and shortening system response time.

We will customize valves and PID control functions according to your application parameters to ensure fast and stable control while maintaining low pressure loss.

Request a Quote

SI-20FDR Gas Mass Flow Controller | High Accuracy - Low DP

The SI-20FDR gas mass flow controller is a high-precision gas flow measurement and control device. It achieves an accuracy of ±0.5% of full scale and is suitable for controlling mass flow even with virtually no available system pressure.

Product SKU: SI-20FDR Gas Mass Flow Controller

Product Brand: Sino-Inst

Price Valid Until: 2099-09-09

Product In-Stock: PreOrder

5

.png)