The SI-10L series liquid flow controller/meter can control the flow rate of liquids, displaying both volumetric and mass flow rates. It can quickly and accurately measure and control the volumetric/mass flow rate of process liquids. It employs a customized high-speed proportional control valve with a unique vent for easy air removal.

The SI-10L series liquid flow controller/meter utilizes patented internally compensated laminar differential pressure technology, widely used for precise continuous measurement and control of cumulative or instantaneous flow rates in pipelines. Applicable media include: water, fragrances, alcohols, benzene, and a range of non-corrosive chemical solvents.

★★★★★

Features

Specifications

| Series | SI-10L | |||||

| Model | LC | LM | MC | MM | BC | BM |

| Measuring Range | 0-(2,5,10…1000)SCCM | 0-(1,2,3…5)SLM | 0-(5,6,10…20)SLM | |||

| Accuracy | ±1.0%F.S | |||||

| Repeatability | ±1%F.S | |||||

| Zero Drift & Full Scale Drift | 0.02% F.S/ ºC/Atm | |||||

| Operating Differential Pressure | 0.1~0.5MPa (specify when ordering) | |||||

| Range Ratio | 50:1 | 100:1 | 50:1 | 100:1 | 50:1 | 100:1 |

| Typical Response Time | 200 milliseconds (adjustable) | |||||

| Analog Quantity | 0~5V、4~20mA | |||||

| Digital Quantity | RS232/485, MODBUS protocol | |||||

| Power Supply | 24VDC | |||||

| Operating Temperature | +10~+50℃ | |||||

| Operating Pressure Drop | <0.01Mpa | |||||

| Operating Pressure | 3 MPa / 10 MPa (flow meter only) | |||||

| Electrical Connection | DB15 hole | |||||

| Protection Class | IP40 | |||||

| Leakage Rate | 1×10-9Pa m³/S | |||||

| Valve | Valve normally closed | / | Valve normally closed | / | Valve normally closed | / |

| Base Material | Stainless steel | |||||

| Sealing Material | Fluororubber, nitrile rubber, EPDM, perfluoroelastomer | |||||

| Body Thread | G3/8 internal thread | G1/2 internal thread | ||||

| Connector | Foldings, ferrules, quick-connect fittings, VCRs, flanges, etc. | |||||

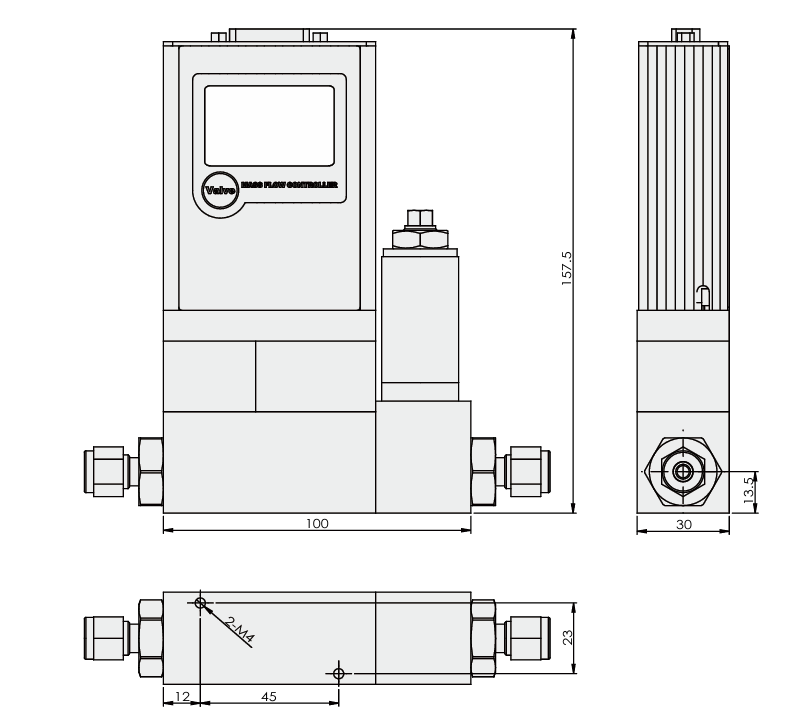

SI-10L-LC Liquid Flow Controller Low-range size

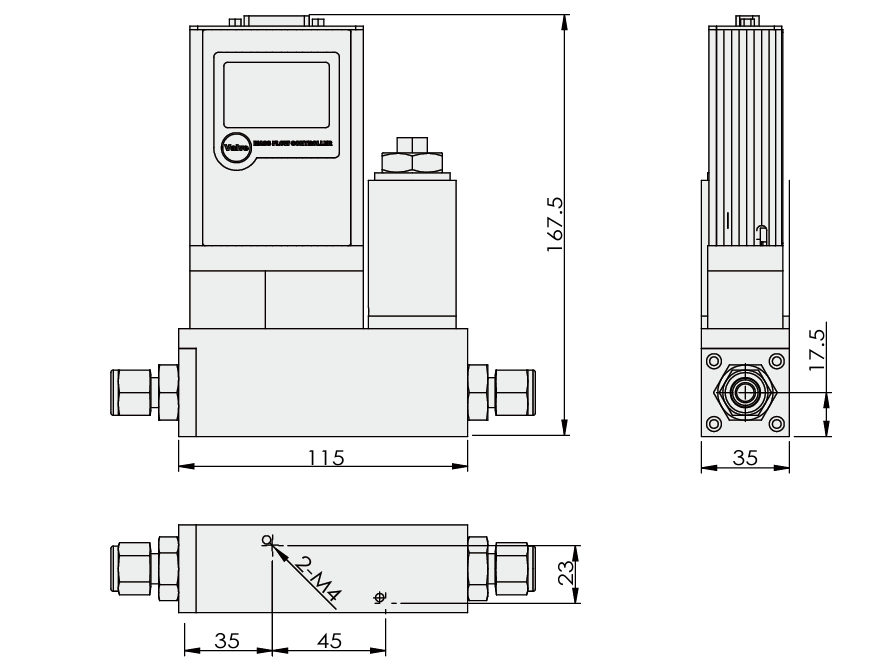

SI-10L-LC Liquid Flow Controller Low-range size SI-10L-MC Liquid Flow Controller Mid-range Dimensions

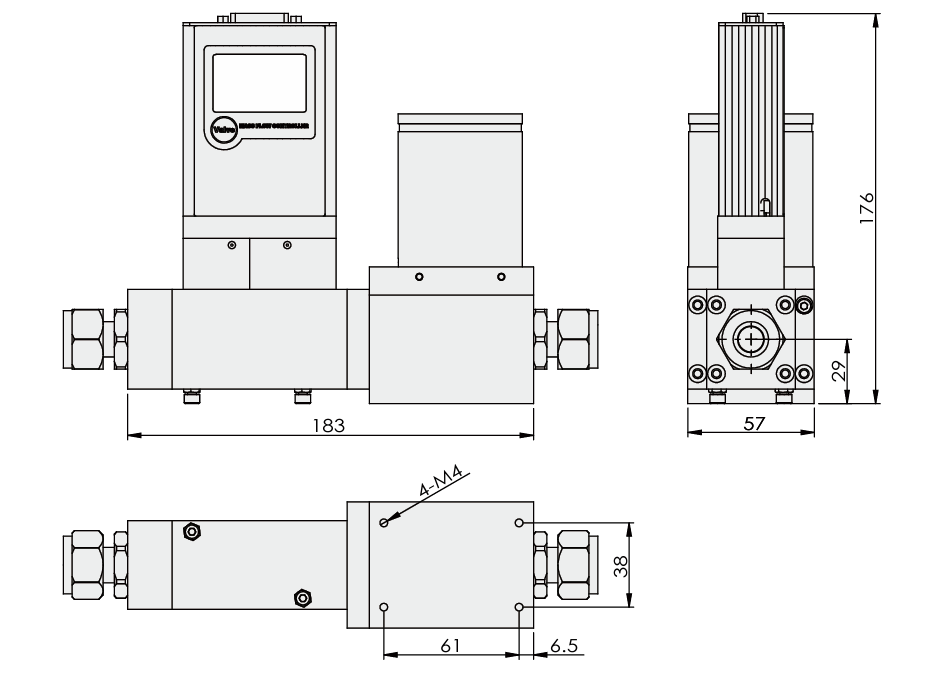

SI-10L-MC Liquid Flow Controller Mid-range Dimensions SI-10L-BC Liquid Flow Controller Large Range Dimensions

SI-10L-BC Liquid Flow Controller Large Range Dimensions

Differential Pressure Liquid Flow Controller/Meter Applications

In practical applications, the SI-10L Laminar Differential Pressure Liquid Flow Controller/Meter is widely used in various fields such as chemical, petroleum, food, and pharmaceutical industries.

In chemical production, liquid mass flow controllers are crucial equipment for ensuring the smooth progress of reaction processes. In chemical reactions, the proportions of various raw materials need precise control; otherwise, reaction efficiency and product quality will be affected. For example, in some polymerization reactions, the amount of different monomers added must strictly adhere to the formulation requirements. Liquid mass flow controllers can accurately control the monomer flow rate in real time, ensuring the reaction proceeds under optimal conditions and improving product purity and yield.

The pharmaceutical industry has even stricter requirements for liquid mass flow control. In the production of pharmaceutical formulations, precise control of liquid flow rate is required in all stages, from dissolving and preparing the active pharmaceutical ingredient to filling. Liquid mass flow controllers can ensure stable drug solution concentrations, avoiding inaccurate drug dosages due to flow fluctuations, thereby ensuring patient medication safety.

In scientific research experiments, liquid mass flow controllers ensure the accuracy and repeatability of experimental results. In research fields such as chemical analysis and biological experiments, precise control of reagent dosage is often required. Liquid mass flow controllers can meet researchers’ needs for high-precision flow control, helping them obtain reliable experimental data.

Furthermore, they offer advantages such as a wide measurement range, good stability, and ease of maintenance, meeting measurement requirements under various operating conditions.

Technical Support

How Does a thermal mass flow controller working principle?

8 Best Mass Flow Controller Manufacturers

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

Guide to Connecting a Thermal Mass Flow Controller to a PLC

The Sino-Inst liquid mass flow controller also boasts numerous advantages. It offers rapid response, adjusting to flow rate changes quickly. Furthermore, it can be connected to computer control systems for automated control and remote monitoring, improving production efficiency and management.

The SI-10L series liquid flow controllers/meters are suitable for university and research institute experiments, manufacturing processes, food analysis, and analytical testing. If you require liquid flow measurement and control, please feel free to contact our sales engineers!

Request a Quote

.png)