SI-10FDR LOW-ΔP Mass Flow Controller is designed for mass flow control in systems with minimal available pressure. Equipped with a proprietary high-flow electromagnetic valve, its low pressure drop ensures minimal system impact, enabling flow control near atmospheric pressure conditions and reducing system response time.

We customize valve and PID control functionality based on your application parameters, ensuring rapid, stable control while maintaining low pressure loss.

★★★★★

Features

Specifications

| Operating status | Operating Temperature | +10~+50℃ | |||

| Maximum Working Pressure | 3MPa/10MPa | ||||

| Requirements for Installation Method/Orientation | >1L/min range, valve must be installed vertically | ||||

| Valve Class | Valve long-term closed | ||||

| Protection Rating | IP40 | ||||

| Material | Stainless steel | ||||

| Signal | Monochrome LCD Display | Simultaneously display flow rate and set | |||

| Digital Output Signal | RS485/RS232 | ||||

| Analog Input Signal | 0-5Vdc / 4-20mA | ||||

| Analog Output Signal | 0-5Vdc / 4-20mA | ||||

| Electrical Signal Interface | DB15 | ||||

| Supply Voltage | 24-30Vdc | ||||

| Supply Current | 0.750Amp | ||||

| Specification | Measurement Range | Low range: 150-600 SLM Medium range: 600~1200 SLM | |||

| Accuracy (under standard conditions after zero adjustment) | ±1%F.S | ||||

| Repeatability | ±1%F.S | ||||

| Zero Drift & Full-Scale Drift | 0.02% F.S/ ºC/Atm | ||||

| Adjustable Ratio of Operating Range/Measurement Range | 2% ~ 100% F.S / 50:1 | ||||

| Maximum Measurable Flow Rate | 100% F.S. (Controllable) | ||||

| Typical Response Time | 200 milliseconds (Adjustable) | ||||

| Start-up Warm-up Time | < 5 seconds | ||||

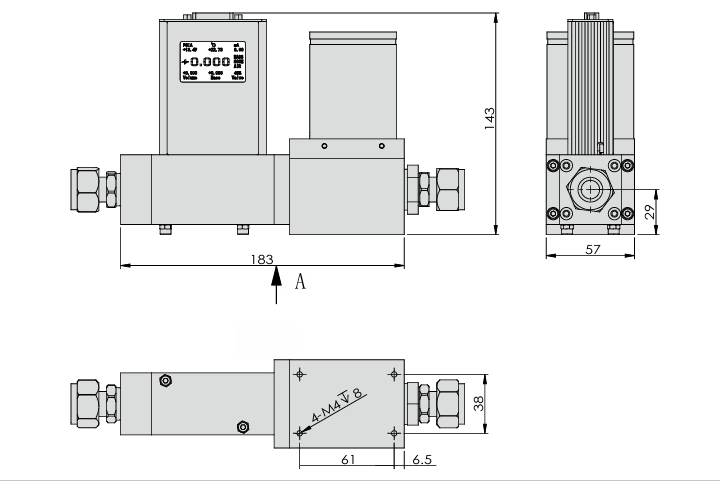

SI-10FDR Low Differential Pressure Gas Mass Flow Controller Size (Low range)

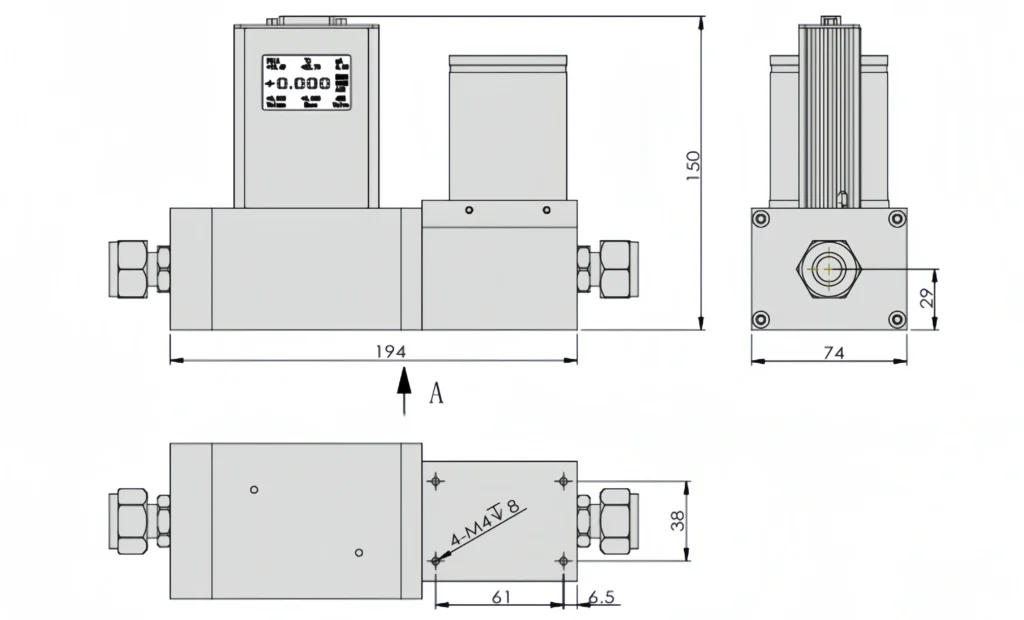

SI-10FDR Low Differential Pressure Gas Mass Flow Controller Size (Low range) SI-10FDR Low Differential Pressure Gas Mass Flow Controller Dimensions (Medium range)

SI-10FDR Low Differential Pressure Gas Mass Flow Controller Dimensions (Medium range)

Low Differential Pressure Gas Mass Flow Controller Applications

The SI-10FDR series low differential pressure gas mass flow controllers are widely used in various industries, such as: process manufacturing, heat treatment, laboratories, environmental protection equipment, food analysis, analytical testing and measurement, etc.

Multivariable measurement and a 50:1 adjustable range ratio allow a single SI-10FDR low differential pressure gas mass flow controller to replace the functionality of multiple devices.

1% accuracy, 1% repeatability, and a control response time of less than 200 milliseconds ensure the normal operation of process gases.

Order Guide

| Model Number | SI-10FDR-L (small range); SI-10FDR-M (medium range); |

| Product Type | 【C】Mass flow controller |

| Pressure Rating Range | 【M】3MPa |

| Field Display Status | 【N】Without LCD display 【X】With LCD display |

| Flow Range | Small range: 【0150L】 150SLM 【300L】 300SLM 【500L】 500SLM 【600L】600SLM Medium range: 【700L】 700SLM 【900L】 900SLM 【1000L】1000SLM 【1200L】 1200SLM 【0000L】 User specified |

| Measured Medium | See density reference table for details. |

| Flow Input Signal | 【A1】0~5VDC 【A2】4~20mA 【A3】1~5VDC |

| Output Signal | 【B1】0~5VDC 【B2】4~20mA 【B3】1~5VDC |

| Supply Voltage | 【5】±15VDC 【4】24VDC |

| Communication Method | 【8】RS485 【2】RS232 |

| Seal Material | 【V】 Fluororubber 【T】 Acrylonitrile rubber 【N】Chloroprene rubber 【Y】Other |

| Connector Type | 【E】φ12 【L】Flange installation 【Y】Other (Contact the manufacturer) |

| Selection Example | SI-10FDR-M C M 0030L 007 A1 B1 5 8 V E |

Why is a pressure difference required between the inlet and outlet of a mass flow controller?

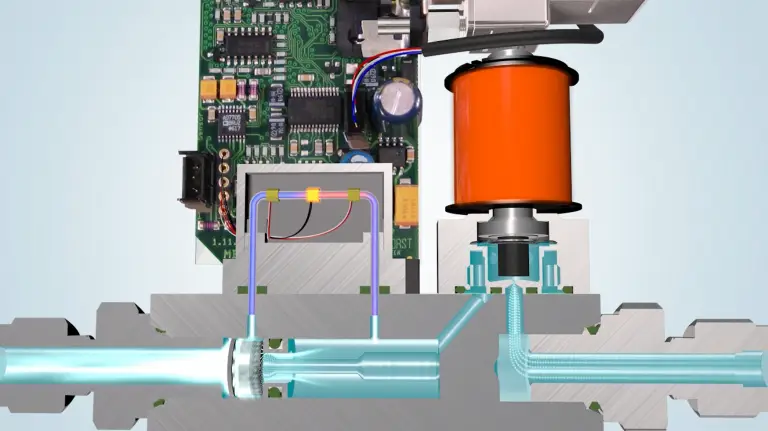

A mass flow controller (MFC) is equipped with an electromagnetic proportional valve to regulate gas flow. The proportional valve controls the flow rate. Due to the presence and operation of the control valve, system resistance increases, resulting in a pressure loss as gas passes through the flow controller. This pressure drop, or pressure difference, occurs between the inlet and outlet of the flow controller.

Some customers experience flow control failures when using MFCs, and a significant reason for this is the failure to meet the required pressure difference between the MFC inlet and outlet.

For example, the operating pressure difference range of most common MFCs on the market is typically around 0.05–0.5 MPa. If the pressure difference between the inlet and outlet is below the lower limit, the gas pressure may not be enough to open the proportional valve to the appropriate position. Therefore, the full-scale value or the set flow rate may not be reached. Conversely, if the pressure difference is too large, exceeding the upper limit, the control valve may not close properly, leading to leakage.

Therefore, when selecting an MFC, users should ideally provide the pressure values, differential pressure values, or port conditions of the flow controller’s inlet and outlet. This allows us to recommend a suitable model and calibrate it according to requirements based on the actual differential pressure, or provide reasonable suggestions to the user.

Of course, in actual use, some operating conditions require minimal pressure loss, meaning a very small pressure drop. This means the pressure difference between the flow controller’s inlet and outlet must be very small, less than the differential pressure range of a typical MFC. For example, applications involving combustible gases such as natural gas, methane, and propane, or many heat treatment processes, all involve low pressure loss requirements. In such cases, our low-differential-pressure gas mass flow controller can be selected. We can provide low-pressure-loss solutions based on the customer’s actual operating requirements, approaching or achieving the low-pressure-loss performance of other brands of flow controllers to meet the customer’s needs.

Furthermore, some special applications require high differential pressures, reaching 5 MPa or even higher. We already have practical applications meeting these requirements and can satisfy the needs of some customers.

CO2 Sensor vs. VOC Sensor: What’s the Difference?

Expert Guide: How a Photoionization Detector Works

The Low Differential Pressure Gas Mass Flow Controller features a digital display screen, allowing operation of gas switching, set flow rate control, and PID valve adjustment. It also supports analog and digital communication, including options for Profibus-DP, Modbus, and RS-485/232 serial communication.

Sino-Inst’s low pressure loss gas mass flow controllers are widely used across various industries, especially suitable for applications where system pressure is easily lost due to flow meters. Examples include: manufacturing processes, food analysis, analytical testing and metering, as well as atmospheric testing systems, environmental monitoring systems, and applications involving natural gas and methane combustion gases, where the inlet pressure is very low but gas flow control is still required.

Contact our sales engineers anytime for customized mass flow controllers!

Request a Quote

Low Differential Pressure Gas Mass Flow Controller | LOW-ΔP-FLOW

SI-10FDR LOW-ΔP Mass Flow Controller is designed for mass flow control in systems with minimal available pressure. Equipped with a proprietary high-flow electromagnetic valve, its low pressure drop ensures minimal system impact, enabling flow control near atmospheric pressure conditions and reducing system response time.

Product SKU: SI-10FDR Series Low Differential Pressure Gas Mass Flow Controller

Product Brand: Sino-Inst

Price Valid Until: 2999-09-09

Product In-Stock: PreOrder

5

.png)