Why should you care about how to calibrate pH meter more than you think? Whether you are managing wastewater treatment, chemical processing, or food manufacturing, a pH sensor is only as accurate as its last calibration.

Over time, all pH electrodes suffer from signal drift caused by aging, fouling, and temperature shifts. A poorly calibrated sensor leads to chemical overdosing, failed quality control, and increased operating costs.

In this guide, we provide a practical, field-oriented tutorial on how to calibrate your sensors, avoid common mistakes, and recognize when it’s time to stop calibrating and start replacing.

By the end of this guide, you will understand:

- How pH calibration actually works

- Which calibration method fits your application

- How to recognize when a sensor should be replaced instead of recalibrated

Why Does Your pH Meter Need Calibration?

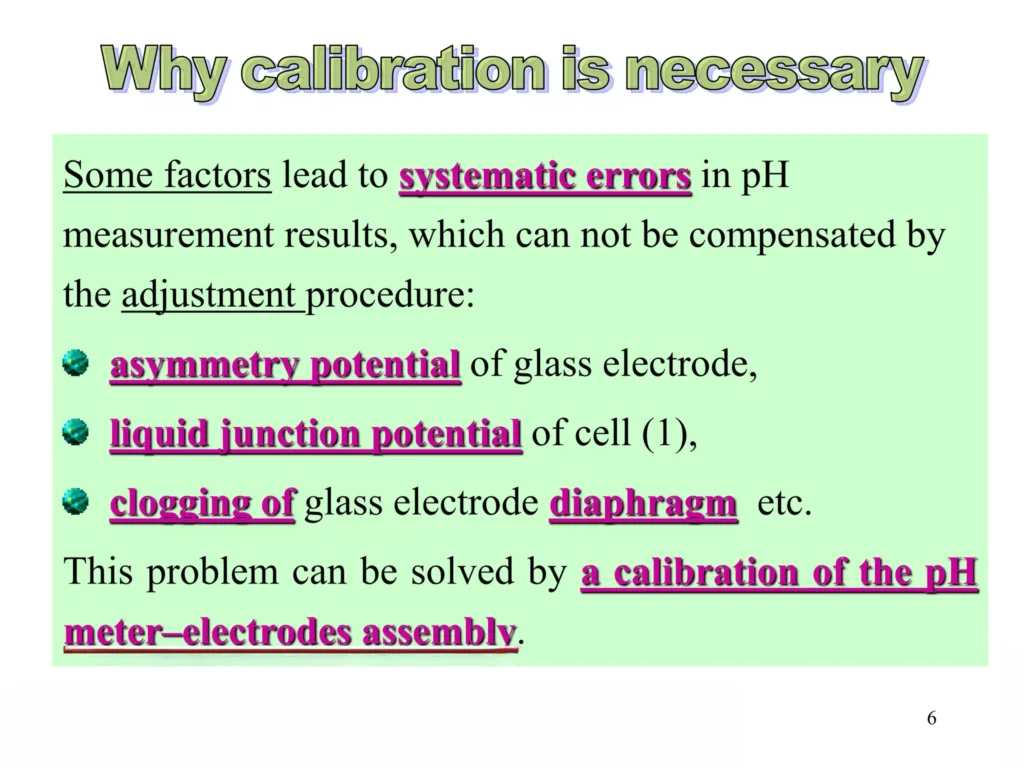

ven the highest-quality industrial pH sensors suffer from Signal Drift. This is a natural chemical process caused by:

- Glass Membrane Aging: The ion-exchange capacity of the glass bulb decreases over time.

- Reference Junction Clogging: Oils, biofilms, or sediments block the junction, leading to “noisy” readings.

- Temperature Fluctuations: pH is temperature-dependent. Without proper calibration at the right temperature, your data is inaccurate.

- Expert Insight: At Sino-Inst, we’ve observed that 70% of “failed” sensors simply need a deep cleaning and a proper two-point calibration rather than replacement.

Risks of Skipping pH Sensor Calibration

From an operational standpoint, uncalibrated pH sensors introduce measurable risks:

- Chemical over-dosing or under-dosing

- Process instability and control loop oscillation

- Failed quality control or regulatory non-compliance

- Increased chemical consumption and operating costs

In wastewater treatment, chemical processing, and food production, pH sensor calibration directly affects safety, cost, and product quality.

Why is pH Meter Drifting? (The Science of Accuracy Loss)

Even the highest quality industrial pH sensors are consumables. Understanding why they drift helps you set a better maintenance schedule:

- Glass Membrane Aging: The sensitive glass bulb loses its ability to exchange hydrogen ions over time, leading to a “low slope” (reduced sensitivity).

- Reference Junction Clogging: In wastewater or high-solids applications, the junction can get blocked by oils or biofilms, causing “noisy” or jumping readings.

- Temperature Variation: pH is a temperature-dependent measurement. Without Automatic Temperature Compensation (ATC), your readings will never be truly accurate.

💡 Pro Tip: Calibration cannot repair physical damage; it is a diagnostic tool to detect when your sensor has reached its end-of-life.

Sino-Inst’s expert opinions

Choose the Right Sensor

Sino-Inst‘s field data demonstrates that sensor selection causes most calibration failures.Standard ceramic junction electrodes deteriorate quickly in wastewater or high-solids conditions, causing drift. Sino-Inst engineers created specialized pH glass and plastic sensors:

- PTFE Junctions: Chemical- and clog-resistant.

- In fouling-prone situations, flat-surface electrodes self-clean best.

- Solid Electrolytes: Reference poisoning prevention.

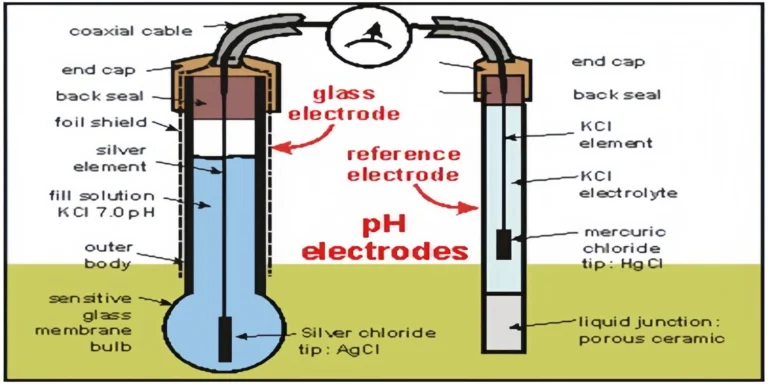

pH Sensor Calibration Principles

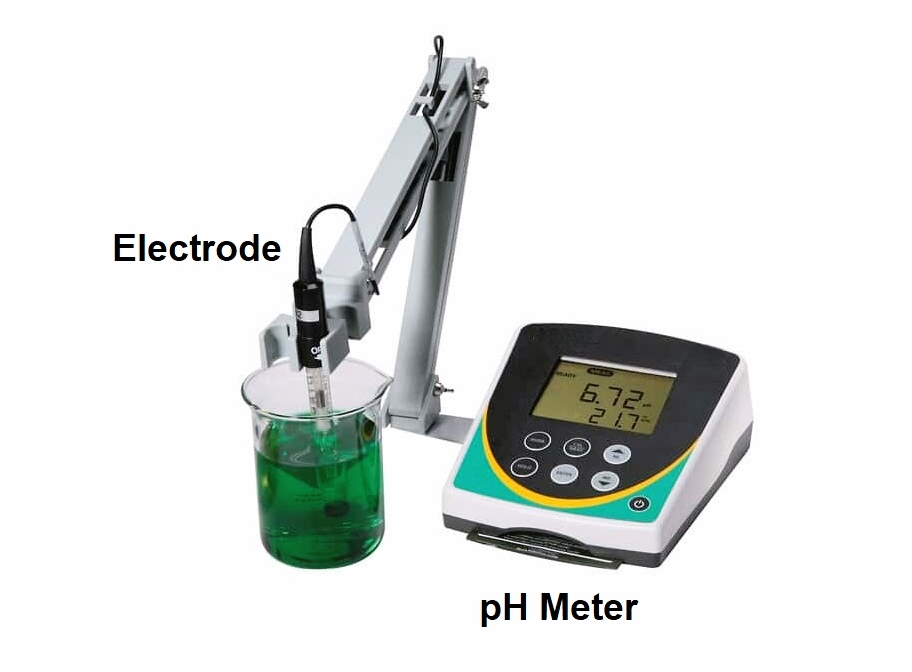

The Nernst equation describes a straight line between pH value and electrode voltage. This is how pH sensors work.

The theoretical slope at 25°C is:

- 59.16 mV for every pH unit

When calibrating, the instrument changes:

- Offset (the zero point is at pH 7)

- Slope (how sensitive it is across the pH range)I

If the slope drops below an acceptable level, successful calibration may no longer be possible. This is often the first clue that something has to be replaced.

Step-by-Step: How to Calibrate a pH Meter Like a Pro

1. Mid-Point Calibration

Uses one buffer, usually pH 7.00.

| Feature | Description |

|---|---|

| Accuracy | Low |

| Corrects offset | ✅ |

| Corrects slope | ❌ |

| Typical use | Quick checks only |

📌 Not recommended for industrial control.

2. Two-Point Calibration (Most Common)

Uses:

- pH 7.00

- pH 4.00 or pH 10.00

| Feature | Description |

|---|---|

| Accuracy | Good |

| Corrects offset | ✅ |

| Corrects slope | ✅ |

| Typical use | Industrial & lab applications |

This is the standard calibration method for most users.

Most Sino-Inst industrial pH controllers support automatic two-point calibration with real-time slope and offset display, allowing users to quickly evaluate sensor health during calibration.

3. Three-Point Calibration

Uses pH 4.00, 7.00, and 10.00.

| Feature | Description |

|---|---|

| Accuracy | High |

| pH range | Wide |

| Complexity | Higher |

| Typical use | High-precision laboratories |

Comparison: Which Calibration Method Do You Need?

| Method | Buffers Used | Accuracy | Best For |

| One-Point | pH 7.00 only | Low | Quick daily spot-checks. |

| Two-Point | 7.00 + 4.00/10.01 | High | Most industrial & lab processes. |

| Three-Point | 4.00, 7.00, 10.01 | Maximum | High-precision scientific research. |

Step-by-Step pH Sensor Calibration Procedure

To make sure your sensor is correct, not just “calibrated,” do these things:

- First, clean the electrode by running it under deionized water. If it was in oily water, mix 5% HCl with water or use a light detergent first.

- For a lint-free dry, use a blot, not a rub. When you rub, you make static energy, which makes the reading move around for minutes.

- In order to set the Zero Point (Offset), you should always begin with a pH level of 7.00.

- Being stable is very important. Don’t confirm the calibration point until the mV number stays the same for at least 30 seconds.

The Slope Test: Check your controller’s Slope percentage after the second point (pH 4 or 10).

Troubleshooting: Why Your Calibration Fails

If your calibration keeps failing, look for these “hidden” culprits:

- The 85% Rule: If your slope falls below 85% (approx. 50 mV/pH), the glass membrane is chemically exhausted. Stop calibrating—it’s time to replace the sensor.

- The Offset Error: If your pH 7.00 reading shows more than ±30 mV, your reference junction is likely contaminated or the electrolyte is depleted.

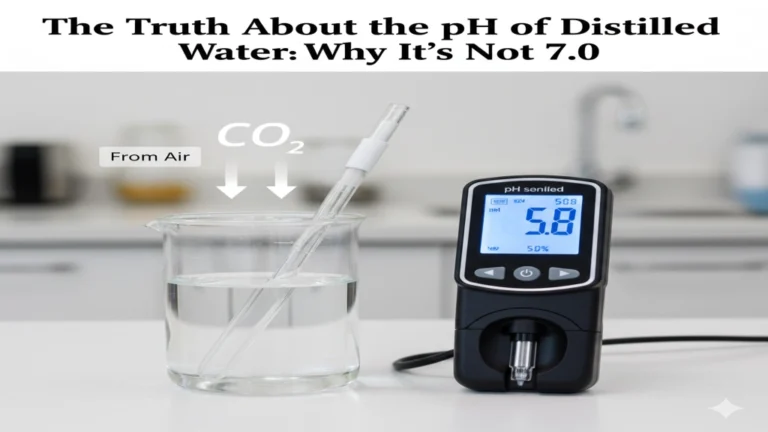

- Expired Buffers: pH 10.01 buffer is notoriously unstable as it absorbs $CO_2$ from the air. Always use fresh, sealed buffer solutions.

Field Experience from Sino-Inst

In industrial environments, repeated calibration failure is often the first warning sign of sensor end-of-life.

Based on sino-inst field data, when a pH electrode cannot maintain a slope above 85% after proper cleaning, continued calibration no longer improves accuracy and replacement becomes the most cost-effective solution.

Stop Calibrating, Start Automating

In high-demand industrial environments, manual calibration is a labor-intensive bottleneck. Sino-Inst’s Digital pH glass sensors and plastic sensors solve this by storing calibration data directly in the sensor head.

The calibration data for our digital pH sensors is stored right in the sensor head. This lets you:

- Plug-and-Play: Calibrate in the lab, and swap it into the field instantly.

- Real-time Diagnostics: Get alerts on your phone or PLC when the slope drops below 85%.

- Rugged Design: Our PTFE junctions are specifically built for harsh wastewater where standard sensors fail.

Conclusion: pH Sensor Calibration Is Required

Learning how to calibrate ph meter is the greatest approach to avoid chemical waste and equipment damage.By following the 85% Slope Rule, you ensure your data is always reliable.

However, calibration can’t fix a sensor that doesn’t fit your environment. To choose the right hardware, check out our expert reviews:

- 📘 [How to Choose the Right pH Electrode]: Find the perfect match for your water conditions.

- 🏆 [Top Plastic-Shell pH Sensors]: Our review of the most durable and cost-effective sensors.

Need a professional solution?[Get a Quote] from Sino-Inst now and stop the “pH Bounce” for good.

FAQ

Related Products

Glass Sensor

Plastic-Shell Sensor

Looking for a Reliable Replacement?

Sino-Inst provides a full range of industrial pH sensors and controllers, designed for:

- Wastewater treatment

- Chemical processing

- High-temperature and high-solid applications

If you are unsure which pH sensor fits your process, the Sino-Inst technical team can help you select the right model based on your operating conditions.

Request a Quote

More Resources

-

How to Get Rid of Chlorine in Water — The Complete Science-Backed Guide (2026)

If you’re searching for how to get rid of chlorine in water, you probably want better‑tasting tap water, healthier skin, or safe water…

-

Is It Safe to Drink Purified Water? Practical Guide to Making a Healthy Choice.

Is it safe to drink purified water? “Is the most crucial question for health conscious consumers when choosing bottled water or home water…

-

5 Kinds of Detector Detects Gas Leaks: Expert Selection Guide

In industrial safety, the margin for error is non-existent. Whether managing a petrochemical refinery, an agricultural greenhouse, or a manufacturing plant, the ability…

-

Total Chlorine vs Free Chlorine: The Complete Industrial Monitoring Guide (2026)

Introduction:Why the Chlorine”Guess”Costs You Money? In water treatment,precision isn’t just a goal;it’s a safety requirement.Many operators ask:”Is total chlorine vs free chlorine same?“The…

-

5 Expert Tips to Put an Explosive Gas Detector for Maximum Safety

Safety is not a variable; it is a constant requirement in industrial process control. When dealing with combustible gases, the difference between a…

-

9 Best VOC Detectors for 3D Printing Safety (2026 Guide)

As 3D printing technology moves from industrial factories to home workshops and small businesses, air quality safety has become a paramount concern. Whether…

.png)