The thermal mass flow controller working principle is one of the most important concepts in modern industrial gas measurement. Whether you work in laboratories, semiconductor manufacturing, environmental monitoring, or industrial process control, understanding how a thermal mass flow controller works is essential for achieving accuracy, efficiency, and safety. This complete guide explains every detail of the thermal mass flow controller working principle, practical examples, applications, advantages, and how to choose the right device for your system.

Table of Contents

- 1. What Is a Thermal Mass Flow Controller?

- 2. Thermal Mass Flow Controller Working Principle Explained

- 3. Key Components Involved in the Working Principle

- 4. Types of Thermal Mass Flow Controllers

- 5. Advantages of Using Thermal Mass Flow Controllers

- 6. Common Industrial Applications

- 7. How to Choose a Thermal Mass Flow Controller

- 8. Supplier Spotlight: Sino-Inst — Trusted Gas Detector & Mass Flow Controller Supplier

- 9. Summary Table

- 10. Frequently Asked Questions

- 11. References

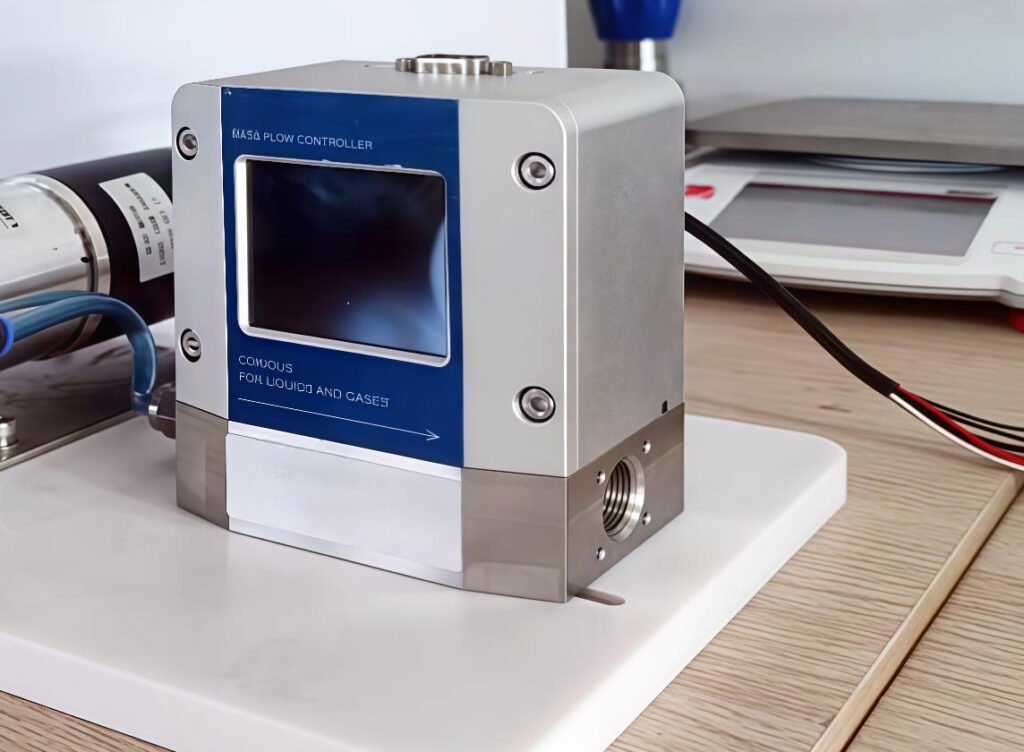

1. What Is a Thermal Mass Flow Controller?

A thermal mass flow controller (MFC) is a precision device designed to measure and control the flow rate of gases using the principle of heat transfer. The core idea behind the thermal mass flow controller working principle is the relationship between gas mass flow rate and the amount of heat carried away by the gas as it passes over a heated sensor. Unlike volumetric meters, thermal mass flow controllers provide accurate mass-based measurements without requiring temperature or pressure compensation.

Because of this accuracy and independence from environmental variables, the thermal mass flow controller working principle is preferred in high-performance applications such as semiconductor production, laboratory research, industrial monitoring, combustion control, and environmental analysis.

2. Thermal Mass Flow Controller Working Principle Explained

2.1 Core Principle: Heat Transfer Proportional to Mass Flow

The central concept behind the thermal mass flow controller working principle is simple yet powerful: as a gas flows across heated sensors, it absorbs heat. The amount of heat absorbed is directly proportional to the mass flow rate, not the volume flow rate. This allows for highly accurate real-time control.

2.2 Step-by-Step Explanation

- A heated sensor element is placed inside the flow path.

- A reference sensor monitors ambient temperature.

- Gas passes through the sensor tube and absorbs heat from the heated element.

- The temperature difference between heated and reference sensors is measured.

- An electronic circuit converts this temperature differential into a mass flow reading.

- The controller adjusts a proportional valve to maintain the set flow rate.

2.3 Why Temperature Difference Matters

When the mass flow increases, more heat is carried away, and the controller compensates by supplying more heat to maintain stability. This dynamic heat exchange lies at the heart of the thermal mass flow controller working principle.

3. Key Components Involved in the Working Principle

A deeper understanding of the thermal mass flow controller working principle requires knowledge of the internal components:

3.1 Flow Sensor Tube

The heated bypass or capillary tube where heat transfer is measured.

3.2 Heater Coil

Provides stable thermal energy used to detect mass flow.

3.3 Temperature Sensors (Upstream and Downstream)

Measure the temperature shift caused by gas mass flow.

3.4 Control Valve

Adjusts the actual gas flow rate based on sensor feedback.

3.5 Microprocessor Unit

Calculates real-time mass flow and performs closed-loop control.

3.6 Calibration and Compensation System

Ensures accuracy across different gas types and environmental conditions.

4. Types of Thermal Mass Flow Controllers

The thermal mass flow controller working principle applies across several types of MFCs:

4.1 Analog Thermal Mass Flow Controllers

Traditional units using analog circuits and voltage-based control signals.

4.2 Digital Thermal Mass Flow Controllers

Modern controllers offering higher precision, digital calibration, and enhanced repeatability.

4.3 Low Differential Pressure Thermal MFCs

Designed for ultra-sensitive environments where minimal pressure drop is required.

5. Advantages of Using Thermal Mass Flow Controllers

- No need for temperature or pressure correction.

- Accurate mass flow measurement.

- Fast response and excellent repeatability.

- Stable long-term performance.

- Low maintenance requirements.

- Ideal for high-purity gas applications.

6. Common Industrial Applications

The thermal mass flow controller working principle makes the devices ideal for:

- Semiconductor manufacturing

- Environmental monitoring systems

- Laboratory gas distribution

- Combustion control

- Biotechnology and pharmaceutical processing

- Industrial automation

7. How to Choose a Thermal Mass Flow Controller

When selecting an MFC, consider the following factors:

- Gas type and purity

- Required flow range

- Accuracy and repeatability

- Pressure and temperature conditions

- Control signal (analog/digital)

- Valve type and response speed

- Compatibility with existing equipment

8. Supplier Spotlight: Sino-Inst — Trusted Gas Detector & Mass Flow Controller Supplier

Sino-Inst is a leading provider of advanced industrial instruments and a highly trusted name in the gas detection and mass flow control industry. As a professional supplier of gas detectors, gas analyzers, dust detectors, mass flow controllers, and dust monitors, Sino-Inst delivers technologically advanced and cost-effective solutions.

Whether you need application-specific customizations or OEM services, Sino-Inst provides reliable mass flow control devices engineered for precision. Their products perfectly embody the thermal mass flow controller working principle with high stability and industry-leading performance.

Popular Products:

- SI-10FA Analog Mass Flow Controller/Meter

- SI-10FD Digital Mass Flow Controller/Meter

- SI-10FDR Low Differential Pressure Gas Mass Flow Controller

If you’re looking for a partner offering accuracy, reliability, and industry expertise, Sino-Inst will be your most trusted supplier.

9. Summary Table

| Feature | Description |

|---|---|

| Measurement Method | Heat transfer proportional to mass flow |

| Main Sensors | Heated element + temperature sensors |

| Key Benefit | Accurate mass flow independent of temperature/pressure |

| Control Mechanism | Closed-loop electronic control with proportional valve |

| Common Applications | Semiconductors, laboratories, industrial gas control |

| Typical Supplier | Sino-Inst Industrial Process & Analytical Instruments |

10. Frequently Asked Questions

1. What is the thermal mass flow controller working principle?

It measures gas mass flow by detecting how much heat is carried away by the flowing gas.

2. Is mass flow better than volumetric flow?

Yes, mass flow is more accurate because it is not affected by temperature or pressure fluctuations.

3. Can a thermal MFC work with any gas?

Yes, but gas-specific calibration or correction factors are required.

4. Are digital thermal mass flow controllers more accurate?

Digital models offer better precision, signal stability, and configuration options.

5. How long does an MFC last?

With proper maintenance, a high-quality MFC can last 8–15 years.

.png)