KPT-4281-K9 pH sensor takes titanium alloy as the core, integrates maintenance free gel electrolyte, international universal interface and multi specification design, and solves the problem that in harsh working conditions such as chromium removal by electroplating, high-temperature chemical solution, high viscosity mud, etc., strong corrosive media are easy to erode electrode structure, electromagnetic interference will lead to data drift, and conventional electrodes are difficult to work stably for a long time.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-100℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

Core product advantages

- Titanium alloy: strong enough to prevent corrosion and electromagnetic interference, so it’s good for harsh environments.

- This design doesn’t need any maintenance because of the gel solution and dielectric.

- Highly compatible: the K9 connector plus PG13.5 thread works with foreign wires, supports 316L stainless steel/PP sheath.

- A range of specs are on hand: can be installed in a variety of ways because of their lengths of 120 mm, 150 mm, 200 mm, 250 mm, and 300 mm.

Accurately adapting to the scene

- Environmental sewage monitoring: online monitoring of sewage treatment plants and industrial sewage discharge outlets;

- Electroplating industry: monitoring of chromium removal process, pH detection of wastewater containing heavy metals;

- Chemical industry: monitoring of high viscosity suspensions, emulsions, and high-temperature chemical fluids;

- Food/Mining: Protein containing liquids such as starch and sugar, pH measurement of mining slurry.

Usage and Maintenance Guide

- Preparation before measurement: Clean the sensor with distilled water or deionized water, and use filter paper to absorb surface moisture (do not wipe the glass film to prevent damage to the sensitive layer); Ensure that the electrode bubble and the liquid interface are immersed in the measured liquid simultaneously to avoid data distortion caused by insufficient contact.

- Idle storage: When the electrode is not in use, clean it and put it into a protective cover containing 3.3 Mol/L KCL immersion solution to maintain the activity of the glass film; Long term immersion in distilled water (prone to dehydration failure), protein solutions (prone to adhesion and blockage), and acidic chloride solutions (accelerating corrosion) is strictly prohibited, and contact with organic silicon oils and fats (damaging sensitive membranes) should be avoided.

- Cleaning and calibration: If the glass film appears semi transparent or deposited, soak and wash it with dilute hydrochloric acid and rinse it with clean water; It is recommended to clean the electrodes once a week and complete calibration with the instrument (especially in high temperature and high impurity scenarios, which need to be shortened to once every 3-5 days) to ensure detection accuracy.

- Life assessment: If the calibration program cannot be completed after cleaning and calibration, or if the detection data continues to drift and respond slowly, it indicates that the electrode has lost its performance and needs to be replaced with a new one in a timely manner to avoid affecting process control.

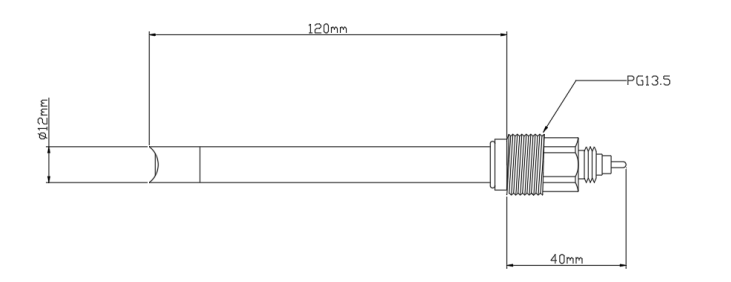

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding electrode sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

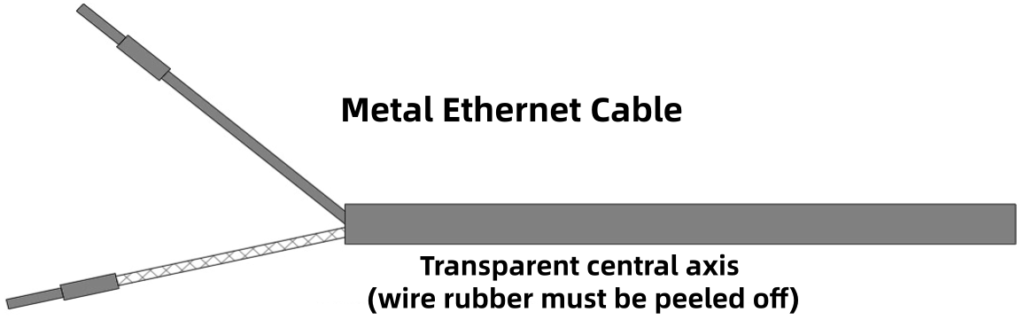

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The main selling point of the KPT-4281-K9 pH sensor is that it is “titanium alloy corrosion resistant and anti-interference.” This means it can correctly solve the problems of pH monitoring in difficult working conditions such as strong corrosion, high electromagnetic interference, high temperature, and high viscosity. It can be used in many different situations, such as electroplating, high-temperature chemical treatment, environmentally safe garbage, and food processing. It is strong because its heart is so sturdy, and it can be used in a lot of different ways, so it can be used in a lot of different fields. It’s a reliable partner for monitoring the environment and working in factories.

Request a Quote

.png)