The GRT1320B pH sensor has a new glass-sensitive membrane and solid electrolyte dual ceramic core construction. This structure combines the benefits of being fast, not needing maintenance, and being highly compatible. Conventional pH sensors have problems with slow response, blockage failure, and not being able to resist corrosion well in harsh industrial settings like high temperatures, strong alkalis, high viscosity suspensions, and viscous liquids that contain proteins. Adapting perfectly to the tough working circumstances of many industries and giving process control and environmental compliance steady and consistent pH monitoring data.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-130℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

Core product advantages

- High temperature sterilization: Suitable for disinfection and sterilization at 130 ℃, effectively measured from 0-95 ℃, stable performance after sterilization;

- Accurate and stable: New high-temperature resistant glass film+double salt bridge reference, fast response and strong anti-interference;

- Maintenance free: Solid electrolytes do not require replenishment, require minimal maintenance, and are suitable for high-purity production needs;

- High compatibility: S8/PG13.5 interface, interchangeable with foreign electrodes, supports 316L/PP sheath;

- Multiple specifications: 120-300mm optional, suitable for different device installation depths.

Accurately adapting to the scene

- High temperature and strong alkali process monitoring: pH detection of high-temperature and strong alkali reaction solutions in the chemical and pharmaceutical industries, such as caustic soda production and alkaline catalyst reaction systems, to withstand extreme environments and ensure data stability;

- Environmental sewage treatment: online monitoring of highly alkaline wastewater and suspended impurity wastewater from sewage treatment plants, adapted to complex water quality, anti blocking design to reduce maintenance frequency;

- Electroplating/Chromium Removal Monitoring: pH detection for heavy metal wastewater and chromium removal processes in the electroplating industry. 316L stainless steel sheath has strong corrosion resistance and is suitable for strong corrosion scenarios;

- Monitoring of high viscosity media: pH measurement of starch slurry, pulp, mud, and protein containing viscous liquids in industries such as chemical, food, and mining, with a dual ceramic core structure to avoid blockage.

Usage and Maintenance Guide

- Before measurement, clean the sensor with distilled water and absorb the moisture to ensure that the sensitive bulb and the liquid junction are submerged in the measured liquid at the same time, avoiding impurities from entering and affecting the data;

- When idle, a protective cover containing 3.3Mol/L KCL soaking solution should be put on. It is strictly prohibited to soak in distilled water, protein solution, or acidic chloride solution for a long time, and keep away from organic silicone oil;

- Clean and calibrate once a week. When semi transparent deposits appear on the glass film, wash it with dilute hydrochloric acid and then rinse it with distilled water. Do not use a hard brush to scratch the sensitive film;

- After standard maintenance, if the calibration still cannot be completed, it indicates that the sensor has lost its responsiveness and needs to be replaced in a timely manner.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the sensor. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

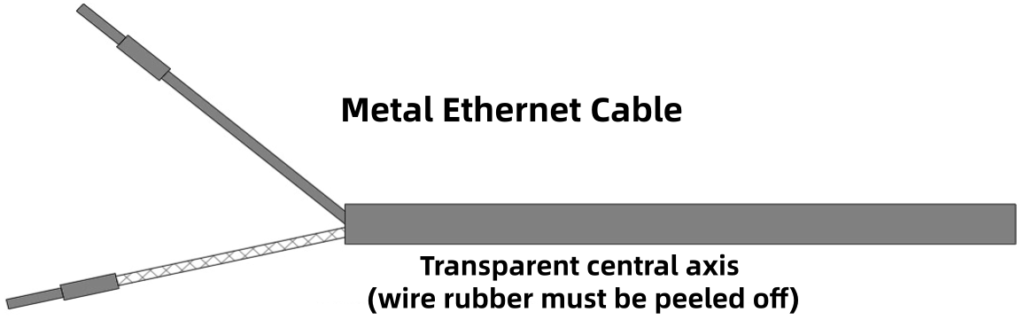

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1320B pH electrode can handle high temperatures and strong alkalis, doesn’t get blocked, and doesn’t need any maintenance. It also works with a lot of other things. These help solve the problems of keeping track of pH levels in difficult industrial settings. Its hard core performance can help with process optimization and meeting environmental standards, whether it’s a strong alkali reaction system at a high temperature, a medium with highly viscous impurities, or electroplating effluent that is highly corrosive.

Request a Quote

.png)