The GRT1130W-VP pH sensor is the “manufacturing leader” in high-temperature sterilization scenarios! Whether it’s high-temperature disinfection in biotechnology, sterilization processes in the pharmaceutical industry, or boiling in beer brewing, ordinary electrodes either cannot withstand high temperatures, or their performance deteriorates after sterilization, making it difficult to replace mismatched interfaces. And it is equipped with a high-temperature resistant solid electrolyte and a two-point ceramic core structure, which can withstand 130 ℃ disinfection and sterilization. It is matched with dual interfaces, multiple lengths, and dual sheaths, supporting foreign electrode exchange, perfectly covering high-temperature working conditions in industries such as biology, pharmaceuticals, food and beverage, making high-temperature complex environment measurement stable and worry free.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-100℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

Core product advantages

- Resistant to sterilization at high temperatures: It can handle sterilization at 130°C and has stable measurements in the 0–95°C range, making it appropriate for the entire workflow at high temperatures.

- Proof against clogs and doesn’t need to be cleaned: liquid junction with a dual ceramic core and a solid electrolyte that can handle high temperatures; doesn’t jam, doesn’t need the electrolyte replaced, and needs very little upkeep.

- Universal with two interfaces: it has both a VP6 plug and a PG13.5 thread, so it can be used with more devices and can be directly connected to foreign sensors.

- Adaptation in many dimensions: It comes in lengths of 120, 150, 200, 250, and 300 mm and has dual sheathing of 316L stainless steel and PP. This makes it ideal for a range of different installations and media.

- Backpressure safety and pressure resistance: 0–0.3 MPa. It can be used in any situation where pressure can’t be applied, and it’s good for high-pressure settings where cleaning takes place.

- Very specific to the industry: Made only for the food and drink, pharmaceuticals, biotechnology, and brewing businesses to meet the needs of high-temperature sterilization.

Accurately adapting to the scene

- Bioengineering: High temperature sterilization and pH monitoring of the production processes of amino acids, blood products, genes, insulin, interferon, etc., with resistance to disinfection processes that do not fail.

- Pharmaceutical industry: Production of antibiotics, vitamins, citric acid and other drugs, precise pH control in the sterilization process to ensure drug quality.

- Beer brewing: the entire process of saccharification, boiling, fermentation, filling, etc., including pH measurement of cold wort, pre/post filtration liquid, deoxygenated water and other media.

- Food and beverage: production of monosodium glutamate, soy sauce, dairy products, fruit juice, yeast, sugar, drinking water, etc., adapted to high-temperature sterilization process, meeting food hygiene requirements.

Usage and Maintenance Guide

Installation key points

- Open box inspection: Confirm that the electrode sensitive bulb has no mechanical damage or bubbles. If there are bubbles, they can be removed by gently shaking vertically; Select the corresponding length of electrode according to installation requirements;

- Sheath matching: Choose 316L stainless steel sheath (strong corrosive medium) or PVC sheath (conventional medium) according to the characteristics of the medium to ensure compatibility;

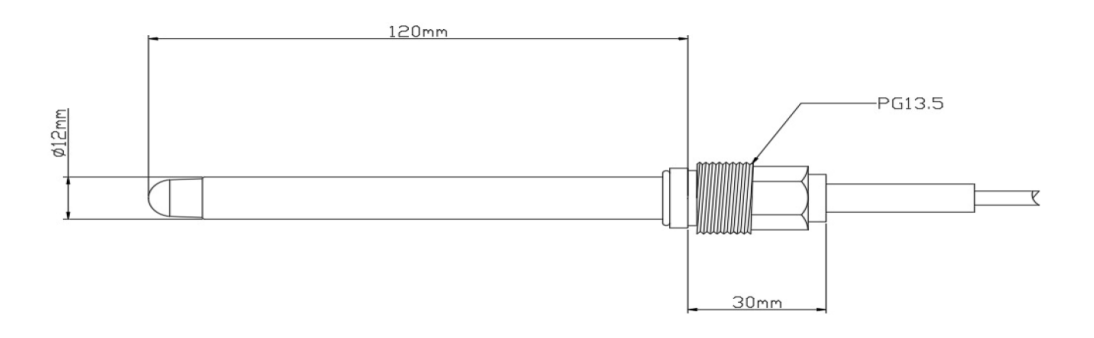

- Interface installation: Fixed with PG13.5 threaded interface, can be paired with protective sleeve or cable head, choose pipeline or container installation method, tighten and fix to avoid shaking;

- Waterproof protection: If the connection between the electrode wire and the electrode is not waterproof, it needs to be sealed with sealant, waterproof joint or heat shrink tubing to prevent the invasion of medium or water vapor;

Maintain

- Daily cleaning: Rinse the sensor with distilled water and dry the filter paper before and after measuring. This will keep dirt and other things from entering into the measured medium. Once a week, clean the liquid interface to keep everything working well.

- Idle storage: After washing, cover it with a 3.3mol/L KCL solution and preserve it in a dry, well-ventilated spot so the delicate bubbles don’t dry out.

- Sediment treatment: Soak the glass film in weak hydrochloric acid for 5 to 10 minutes, then rinse it off if it looks foggy or glued together. Don’t scratch the delicate film with a brush that has strong bristles;

- Calibration cycle:It is best to calibrate the instrument once a week, especially when it is used in strong acids or thick liquids, to make sure the measurements are correct. Stick to the calibration frequency; don’t linger in distilled water, protein solutions, or acidic chloride solutions for too long, and don’t touch organic silicone oils because they could damage the sensors.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

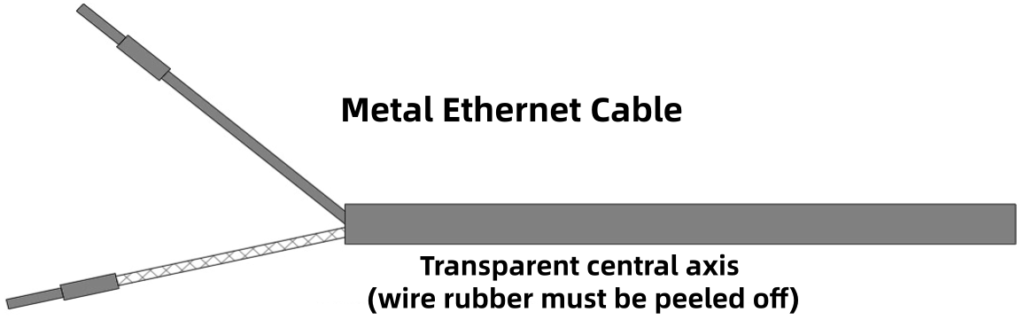

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

For a long time, the GRT1130W-VP pH sensor was just one of many options for high-temperature methods in fields like biology, pharmaceuticals, and food and drink. Now, though, it’s the only choice. This is because it can handle sterilization at high temperatures, works with both inputs, and can be used in a lot of different ways.

Regular sensors don’t work well at high temperatures, break after being sterilized, and don’t work well with different kinds of tools. This fixes all of those problems. It doesn’t need a lot of hard upkeep, and it can also swap out costly foreign electrodes for ones that are just as good. This makes pH measuring in situations where high-temperature sterilizing is needed dependable and correct.

You can now get exclusive selection solutions, advice on how to use them in high-temperature situations, and one-on-one technical help. We’ll help you every step of the way to make sure you can keep an eye on the quality of the high-temperature steps and keep the production processes running smoothly.

Request a Quote

.png)