The GRT1120PD differential pH sensor is based on innovative differential technology and features a durable structural design, making it easy to overcome monitoring pain points in harsh environments. It reduces the risk of data drift and frequent maintenance in complex chemical media such as acidic substances, organic solvents, and hydrocarbons that traditional dual electrode pH sensors often suffer from reference contamination and closed-loop interference. Provide stable and reliable solutions for industrial precision measurement.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| ORP Range | -1500—+1500mV |

| Sensitivity | pH:±0.01pH ORP:±0.5mV |

| Temperature Range | 0-60℃ |

| Pressure resistance | 3bar |

Core product advantages

Differential three electrode technology:

replacing traditional dual sensors, reducing reference pollution, and eliminating closed-loop circulation

Salt bridge replaceable design:

3/4 “plastic shell model supports salt bridge replacement, extending service life

Ultra high measurement accuracy:

pH ± 0.01pH, ORP ± 0.5mV, more accurate data

Universal compatibility:

PG13.5 threaded interface, can be flexibly installed with protective sleeve

Accurately adapting to the scene

- Chemical production scenario: real-time monitoring of pH/ORP for acid-base synthesis reactions, organic solvent preparation, chemical reagent production and other processes, resistant to corrosion from various chemical media, and avoiding the problems of traditional sensor contamination and data drift;

- Industrial wastewater treatment scenario: For severe water quality such as high concentration organic wastewater, acid-base wastewater, and residual solvent wastewater, precise monitoring of parameter changes in key processes such as biochemical treatment and neutralization reactions can be carried out to assist in process optimization and regulation;

- Fine Chemicals and Pharmaceutical Intermediates Scenario: This is helpful for producing aromatic compounds because it enables you change pH and ORP very precisely. It is also used to make certain solvents, pure chemicals, and other things. It meets rigorous quality control standards since it can find variations in pH levels within a range of ±0.01pH.

- Petrochemical scenario: It can be used to keep a watch on the production, separation, and recovery of hydrocarbons and ketones. It can also keep operating successfully even when the solvents are quite strong and the circumstances are bad.

Usage and Maintenance Guide

- Daily cleaning: Rinse the electrodes with distilled water before and after measurement to avoid residual media

- Idle storage: Cover with a protective cover containing 3.3mol/L KCL solution and store in a dry and ventilated place

- Salt bridge replacement: Operate the 3/4 “plastic shell model according to the instructions, soak and activate for 24 hours after replacement, and then calibrate again

- Calibration cycle: It is recommended to calibrate once a month, and for high pollution conditions, it should be shortened to once a week

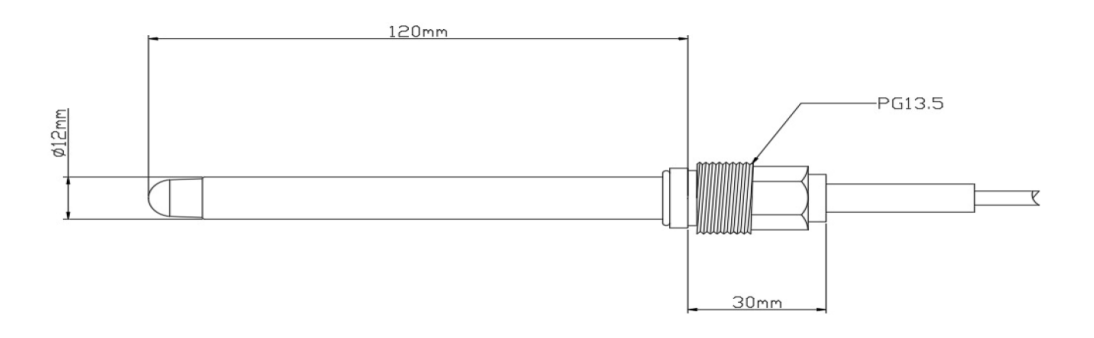

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

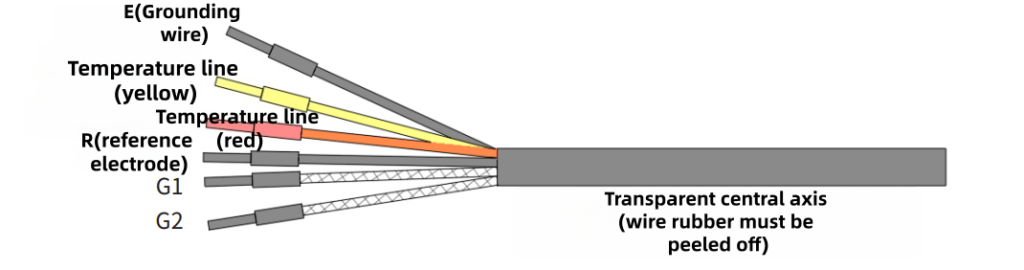

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

In harsh environments including chemical engineering, wastewater treatment, and fine chemical processing, the GRT1120PD differential pH electrode solves contamination and drift issues with three electrodes. The data is accurate, with a margin of error of only ± 0.01 pH. The flexible PG13.5 interface can be configured in many ways. Replace the salt bridge to save money. It is reliable, durable, and easy to maintain, whether you are monitoring production or quality. Exclusive selection, full installation guidelines, and expert assistance are now available from Consultation. This simplifies pH/ORP monitoring in challenging work conditions and ensures production and quality.

Request a Quote

.png)