GRT1110-AS7 pH sensor relies on core designs such as gel electrolyte and anti pollution ring junction to accurately solve the monitoring pain points under severe working conditions, reducing the problems that traditional pH electrodes often face in complex measurement scenarios such as industrial sewage and colloidal media, such as clogging, electrode poisoning, and the need for frequent electrolyte supplementation. Provide convenient, durable, and stable solutions for pH measurement in industrial processes.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95 |

Core product advantages

Maintenance free and worry free design: gel electrolyte does not need to be supplemented, reducing on-site operation and maintenance workload

Anti poisoning and anti pollution: Salt bridge can prevent S ² ⁻, CN ⁻ plasma poisoning, and the ring PTFE interface is not easily blocked

Stable and excellent performance: low internal resistance, fast response, zero potential of 7 ± 0.5mV, theoretical percentage slope ≥ 95%

Widely applicable scenarios: sensitive films made of special materials, suitable for various complex media such as colloids and sewage

Flexible and convenient installation: standard PG13.5 thread, supports pipeline installation and sleeve matching, compatible with BNC connectors or pin terminals

Ideal Application Scenarios

Industrial wastewater treatment scenario: Suitable for pH online monitoring of various industrial wastewater and biochemical treatment wastewater, anti pollution interface is not easily blocked by suspended impurities, and resistant to complex ion corrosion in wastewater;

Colloidal medium measurement: It can accurately measure the pH value of various colloidal solutions, such as chemical colloidal raw materials, food processing colloidal systems, etc. The special sensitive membrane material avoids medium adhesion;

Conventional industrial process monitoring: suitable for routine pH measurement in industries such as chemical, electronics, and pharmaceuticals, compatible with various acidity meters, and installed flexibly to adapt to pipeline or container scenarios;

Usage and Maintenance Guide

Installation key points

- Open box inspection: Confirm that there is no mechanical damage to the sensitive bulb and electrode body. If there are bubbles in the bulb, gently shake it vertically to remove them;

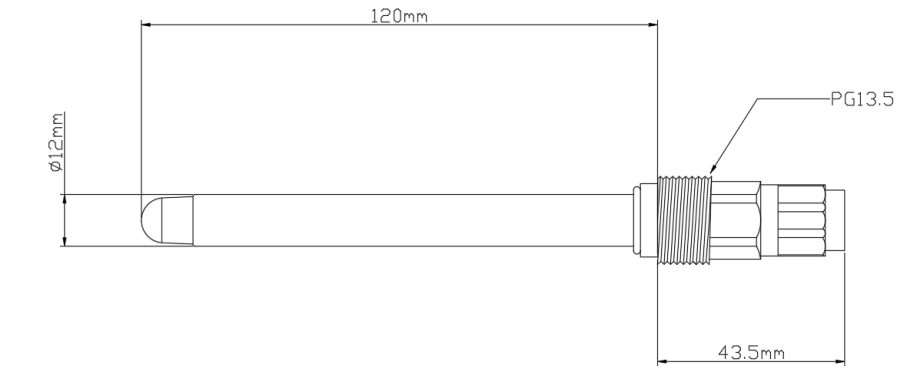

- Interface installation: PG13.5 threaded interface is used, matched with corresponding protective sleeve or cable head, and pipeline installation method can be selected to ensure stable fixation;

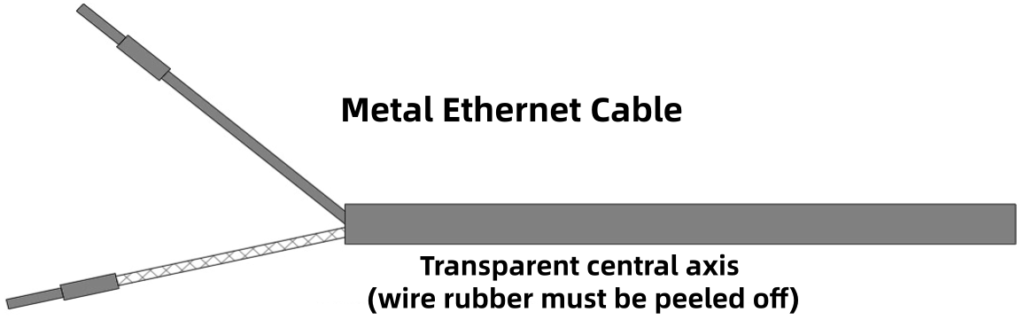

- Stripping specification: Peel off the metal wire layer, thoroughly remove the conductive black skin of the transparent central axis, and avoid signal interference;

- Waterproof protection: If the electrode wire connection is not waterproof, it needs to be sealed with sealant, heat shrink tubing, or waterproof joints to prevent moisture;

- Connector adaptation: Depending on the type of acidity meter interface, choose BNC standard connectors or pin type terminal blocks for docking to ensure good contact.

Maintain

- Daily cleaning: Rinse the electrode with distilled water before and after measurement, dry the filter paper to prevent impurities from entering the measured liquid; Clean thoroughly once a week to ensure performance;

- Idle storage: After washing, put on a protective cover containing 3.3mol/L KCL solution and store in a dry and ventilated place to prevent sensitive bubbles from drying out;

- Sediment treatment: When the glass film appears semi transparent or deposited, wash it with dilute hydrochloric acid and then rinse it with distilled water to avoid scratching with a hard brush;

- Calibration cycle: It is recommended to calibrate the instrument once a week to ensure measurement accuracy;

- Taboo: Avoid prolonged immersion in distilled water, protein solutions, or acidic chloride solutions, and do not come into contact with organic silicone oils.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and sensor body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the sensor. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

Whether it is the complex working conditions of industrial wastewater or the precise measurement of colloidal media, the GRT1110-AS7 pH electrode can calmly cope with various challenges with its core advantages of anti pollution, anti poisoning, and maintenance free. The gel electrolyte eliminates the trouble of supplement, solves the plugging pain point by circular connection, and is flexibly installed by standard interface adaptation. It is a cost-effective choice for online pH monitoring in industrial processes. By consulting now, you can obtain exclusive selection solutions, detailed installation guidance, and one-on-one technical support, making pH measurement more worry free and stable under complex working conditions, helping to smooth the production process and achieve precise quality control!

Request a Quote

.png)