GRT1120B pH electrode is specially designed for complex working conditions with strong alkali and high viscosity! When measuring strong alkaline wastewater, high viscosity suspensions, and protein containing viscous liquids, are you always troubled by poor electrode alkali resistance, clogged interfaces, and tedious maintenance? Ordinary electrodes cannot withstand strong alkaline corrosion and are easily blocked by viscous substances.

Supplementing electrolytes is also time-consuming and laborious. It is equipped with two-point ceramic core fluid to connect, prevent blocking and resist sticking, and gel electrolyte is free of supplementation. It supports flexible adaptation of multiple lengths and multiple sheaths, which can easily break the pH monitoring pain points of strong alkali and high viscosity media, making it easier to measure under complex conditions.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

Core product advantages

Corrosion resistance to strong alkali: specially designed for the treatment of strong alkali wastewater, the electrode body and key components have excellent alkali resistance, and can withstand high concentration alkaline solution erosion for a long time

Anti blocking and anti sticking strength: Two point ceramic core liquid interface, uniform pores and anti sticking, not easily blocked by viscous substances and suspended particles, suitable for high viscosity suspensions and emulsions

Electrolyte free: gel dielectrics are pre charged at one time, and there is no need to supplement in the whole process, so the maintenance amount is greatly reduced and the operation and maintenance cost is reduced

Wide adaptability: supports multiple length options of 120/150/200/250/300mm, can be paired with 316L stainless steel or PVC sheath, suitable for different installation scenarios

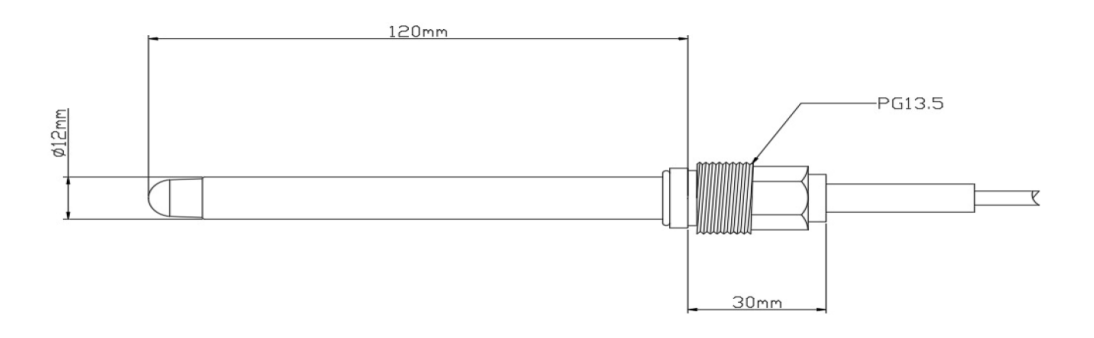

Universal interchangeability: Standard PG13.5 threaded socket, can be directly exchanged with foreign electrodes, replacing old equipment without additional modification

Accurately adapting to the scene

- Strong alkali wastewater treatment: specifically designed for monitoring strong alkali wastewater, it can withstand corrosion from high concentration alkaline solutions and is suitable for pH online monitoring in the treatment process of strong alkali wastewater in industries such as chemical and electroplating;

- Measurement of high viscosity media: Accurately measure the pH value of high viscosity suspensions, emulsions, and protein containing viscous liquids, such as monitoring the production process of industries such as starch, sugar, mud, and pulp;

- Electroplating/Chromium Removal Monitoring: Suitable for plating solution monitoring and online monitoring of chromium removal processes in the electroplating industry, resistant to plating solution corrosion, preventing impurity blockage, and ensuring process stability;

- Multiple scenarios in the chemical industry: pH measurement of complex media in industries such as chemical drugs, dyes, pigments, and mining, compatible with various working conditions such as strong alkali and high viscosity;

Usage and Maintenance Guide

Installation key points

- Open box inspection: Confirm that the electrode sensitive bulb has no mechanical damage or bubbles. If there are bubbles, they can be removed by gently shaking vertically; Select the corresponding length of electrode according to installation requirements;

- Sheath matching: Choose 316L stainless steel sheath (strong corrosive medium) or PVC sheath (conventional medium) according to the characteristics of the medium to ensure compatibility;

- Interface installation: Fixed with PG13.5 threaded interface, can be paired with protective sleeve or cable head, choose pipeline or container installation method, tighten and fix to avoid shaking;

- Waterproof protection: If the connection between the electrode wire and the electrode is not waterproof, it needs to be sealed with sealant, waterproof joint or heat shrink tubing to prevent the invasion of medium or water vapor;

Maintain

- Daily cleaning: Rinse the electrode with distilled water and dry the filter paper before and after measuring. This will keep dirt and other things from entering into the measured medium. Once a week, clean the liquid interface to keep everything working well.

- Idle storage: After washing, cover it with a 3.3mol/L KCL solution and preserve it in a dry, well-ventilated spot so the delicate bubbles don’t dry out.

- Sediment treatment: Soak the glass film in weak hydrochloric acid for 5 to 10 minutes, then rinse it off if it looks foggy or glued together. Don’t scratch the delicate film with a brush that has strong bristles;

- Calibration cycle:It is best to calibrate the instrument once a week, especially when it is used in strong acids or thick liquids, to make sure the measurements are correct. Stick to the calibration frequency; don’t linger in distilled water, protein solutions, or acidic chloride solutions for too long, and don’t touch organic silicone oils because they could damage the electrodes.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

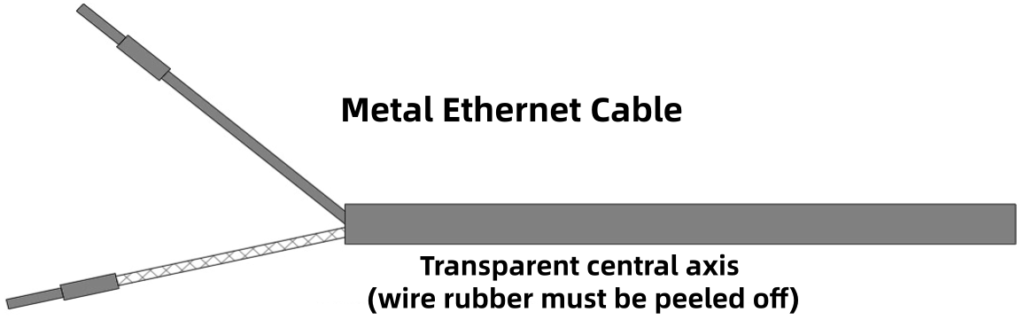

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1120B pH electrode, with its core advantages of alkali resistance, anti adhesion, corrosion resistance, and maintenance free, has become a reliable choice for pH monitoring of strong alkali and high viscosity media. Multi length and multi sheath adaptation meet different installation needs. PG13.5 thread supports foreign electrode exchange, greatly reducing replacement costs. Whether it is strong alkaline wastewater, high viscosity suspension, or complex working conditions in industries such as chemical and electroplating, it can stably output accurate data.

By consulting now, you can obtain exclusive selection solutions and one-on-one technical support, providing you with full support throughout the process, making pH measurement more worry free and efficient under complex working conditions, and helping the production process run smoothly and quality control be precise and in place! Choosing GRT1120B means choosing stable measurement and convenient operation and maintenance under strong alkaline conditions!

Request a Quote

.png)