GRT1320 pH electrode is a reliable workhorse designed for biotech, pharmaceutical, food, and beverage industries—perfect for scenarios that need high-temperature sterilization and stable pH monitoring. With its dual ceramic core and high-temperature solid electrolyte, it handles 130℃ sterilization (common in food/pharma safety processes) and continuous measurement from 0-95℃. No need to refill electrolytes, easy to install with standard PG13.5 thread, and compatible with stainless steel or PP sleeves—it’s built to fit your daily production needs without extra hassle.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 pH |

| Theoretical percentage slope | ≥ 95 |

| Zero potential | 7±0.5 |

| Temperature Range | 0-130℃ |

| Pressure Range | 0—0.3 |

Main Benefits

Can be sterilized and is heat-resistant:

can handle 130°C high-temperature sterilization (no damage after repeated use) and works stably at 0–95°C. This makes it perfect for boiling beer, sterilizing dairy, and pharmaceutical production lines that need to be very clean.

Anti-Clog & Low Maintenance:

The dual ceramic core design stops proteins, sediments, and thick liquids (such fruit juice or fermentation broth) from becoming stuck. It also doesn’t need a lot of care. You don’t need to replenish electrolytes; just clean and calibrate once a week. This saves your team time.

Installation and Replacement are Simple:

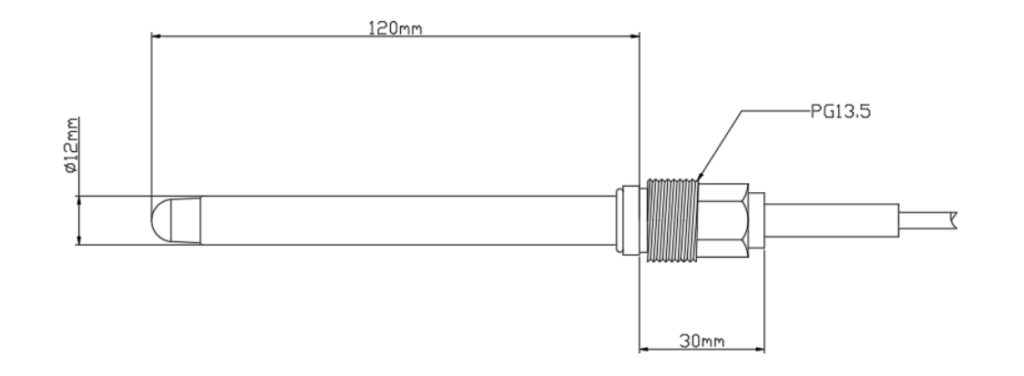

Most industrial tools can use the standard PG13.5 pin, and you don’t have to change anything about your setup to replace electrodes from brands based outside the country. You can pick a length that fits your tanks or pipes; options range from 120 mm to 300 mm in 50-mm increments.

Tough and leak-proof:

Withstands 0.3MPa of pressure (no back pressure) to keep pipes and reaction tanks from leaking. Stainless steel/PP sleeves don’t rust when they come into contact with typical food and drug media. They survive a long time, even with regular use.

Stable Readings:

It has a reliable zero potential and a theoretical percentage slope of at least 95%, so you can trust the data for process control (for example, making sure the quality of beer fermentation or the accuracy of pharmaceutical synthesis).

Where Can You Use It?

- Biotechnology looks at the pH of insulin, blood products, or amino acids and makes sure that they are sterile and can grow at high temperatures.

- Pharmaceuticals: These are great for making antibiotics, vitamins, or citric acid because they are made in very clean and precise conditions.

- Beer Brewing: Does the whole process, from mashing to heating to fermentation to filling. It can deal with hot temperatures and things that are used to make alcohol.

- Food and Drink: It makes soy sauce, dairy products, fruit juice, sugar, and drinking water. It can also be used with thick liquids and sterilization steps.

How to Use & Maintain It

- Before you take a reading, wash the sensor with pure or deionized water, and then use filter paper to dry it. Make sure that both the sensor bulb and joint are fully underwater in the liquid to keep the data correct and the pollutants out.

- Cleaning Tips: If the glass bulb has any sediment on it, soak it in a week hydrochloric acid solution for 5 to 10 minutes and then rinse it with pure water. Don’t scrape it with a strong brush; the delicate bulb will be hurt.

- Calibration: Do this once a week (more often for complex media like fermentation broth). Use fresh pH7.00 buffer solution for calibration, plus pH4.00 (acidic media) or pH10.00 (alkaline media) if needed. It only takes 5 minutes!

- Replacement tip: If the sensor still won’t calibrate after proper maintenance, it’s time to replace it—no need to waste time on repairs.

- Storage: When not in use, clean the electrode first, then store it in the protective cap filled with 3.3Mol/L KCL solution. Never leave it soaking in distilled water or expose it to silicone grease—this shortens its life.

- Waterproof Note: The wire connection isn’t waterproof! Wrap it with waterproof tape or use a dedicated junction box to prevent moisture damage (critical for wet production areas).

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Remove the electrode protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

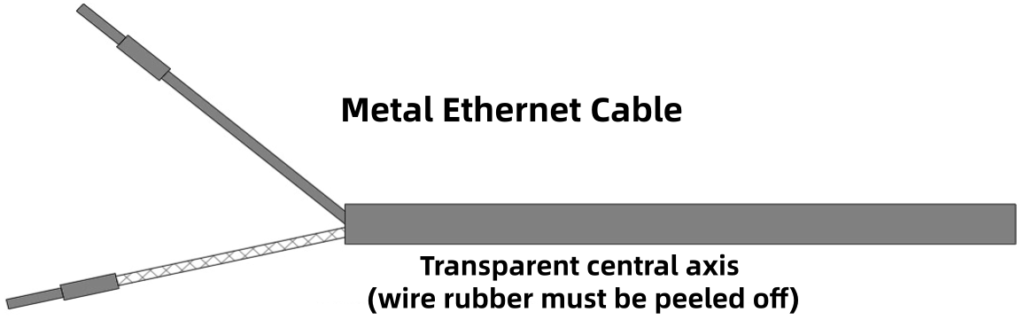

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1320 is the ideal pH sensor for food, medicines, and biotech since it is easy to use, doesn’t need to be replaced often, and works well for cleaning at high temperatures. Sino-Inst, a company that is well-known for creating industrial sensors and has a lot of experience in the food and drug industry, made it. You don’t have to worry about your sensors failing when you’re producing stuff since we make sure they work well.

Request a Quote

.png)