The KPT2160CU pH glass sensor, with its new sensitive membrane, fillable electrolyte design, and anti bubble structure, solves the problem of the stability and accuracy of pH detection directly affecting process safety in low conductivity/pure water scenarios such as chemical treatment of circulating water in power plants and water quality control in reverse osmosis systems. Becoming the professional choice for low conductivity water quality pH monitoring, adapting to domestic and international equipment exchange, and providing reliable data support for the pure water field.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.4 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

| Internal resistance | ≤ 250 MΩ(25℃) |

Scope of Application

- Used for detecting the oxidation-reduction potential of circuit boards and chromium containing wastewater treatment.

Core product advantages

Fast and stable response, precise detection:

Using a new type of glass sensitive film, internal resistance ≤ 250 M Ω at 25 ℃, fast response speed and strong stability; Theoretical percentage slope ≥ 95%, zero potential controlled at 7 ± 0.5, capable of accurately capturing subtle pH changes in low conductivity water quality.

Long term durability and flexible maintenance:

Supports electrolyte filling design, which can extend the service life of sensors by supplementing electrolyte; Equipped with an easily refillable electrolyte chamber, it is easy to operate and reduces maintenance costs.

Anti bubble interference, high reliability:

Adopting a hemispherical glass film structure, it can effectively prevent bubble adhesion, avoid detection data drift caused by bubbles, and ensure monitoring reliability under complex working conditions.

Universal adaptation, easy installation:

equipped with PG13.5 standard threaded socket, can be interchanged with foreign sensors, strong compatibility; Support the installation of 316L stainless steel sheath or PP sheath to meet different on-site environmental requirements.

Accurately adapting to the scene

Chemical treatment of circulating water in power plants: precise measurement of pH for low conductivity circulating water, providing data support for the cooling system and water quality chemical treatment process of power generation units, ensuring the anti-corrosion and anti scaling effects of equipment.

Reverse osmosis system water quality control: suitable for reverse osmosis cleaning circulating water and monitoring of pH adjustment between two-stage system membranes, helping to optimize desalination rate and avoid damage to membrane components due to abnormal pH.

Universal pure water field testing: It can be used for pH monitoring in the pure water preparation process of industries such as electronics and pharmaceuticals, as well as for pH measurement needs of other low conductivity water quality, suitable for high-purity water quality testing scenarios.

Usage and Maintenance Guide

- Before measurement, the sensor should be washed in distilled water or deionized water, and the water should be absorbed dry with filter paper to ensure that the electrode bulb and the liquid junction are immersed in the measured liquid at the same time, avoiding impurities from interfering with the detection.

- When the sensor is idle, it needs to be cleaned and put into a protective cover containing 3.3Mol/L KCL immersion solution to maintain the activity of the sensitive membrane. It is strictly prohibited to soak it in distilled water, protein solution or acidic chloride solution for a long time, and avoid contact with organic silicon oil.

- If the glass film appears semi transparent or deposited, it can be washed with dilute hydrochloric acid and rinsed clean with water; It is recommended to clean the electrodes once a week and coordinate with the instrument to complete calibration to ensure detection accuracy.

- When the sensor cannot complete the calibration procedure after maintenance, it indicates that it has lost its responsiveness and needs to be replaced with a new one in a timely manner.

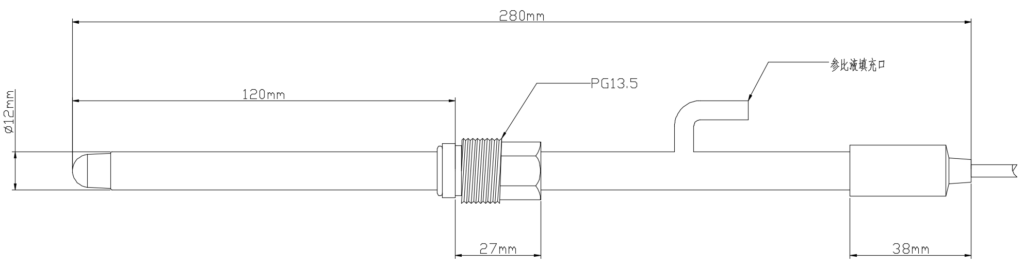

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the electrode protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding electrode sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

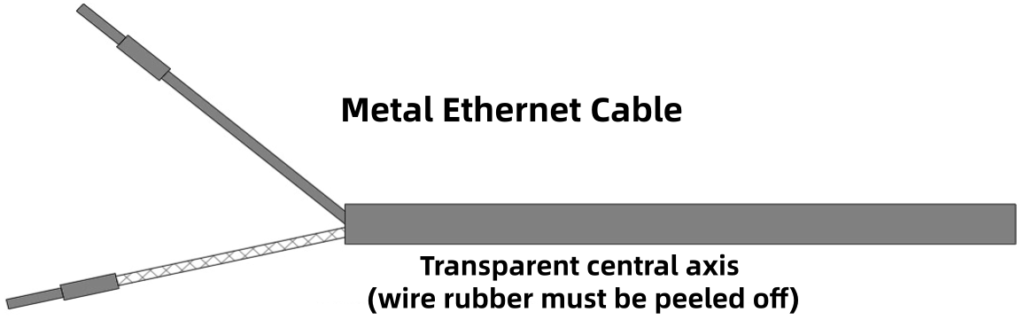

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

As a specialized equipment for low conductivity water quality pH detection, KPT2160CU pH glass electrode has the core advantages of fast and stable response, long-term durability, and universal adaptability, accurately matching the monitoring needs of power plant circulating water, reverse osmosis system, pure water preparation and other scenarios. Its electrolyte filling design and international standard threaded interface not only reduce maintenance costs but also improve equipment compatibility, making it a reliable partner for pH monitoring in the industrial pure water field.

Request a Quote

.png)