The Triboelectric In-line Dust Monitor is a professional instrument that monitors dust concentration in real time by directly inserting it into the pipeline or container. It utilizes the charge generated by dust particles flowing around the probe to determine the online dust emission rate (mg/sec) or emission concentration (mg/m³).

It outputs a control signal to activate a dust emission exceeding standard alarm. It also continuously records the total amount or concentration of dust particles. Typical applications include detecting filter bag damage in baghouse dust collectors, monitoring the total amount of powdered material recovered and transported products, and monitoring the flue gas emission concentration of boilers of various sizes and fuels.

★★★★★

Features

- Using the most advanced AC coupling technology, it has high dust detection sensitivity and good linearity. Dust contamination of the probe will not affect the measurement sensitivity and requires no maintenance or cleaning.

- Direct contact with the measured medium avoids sampling delay.

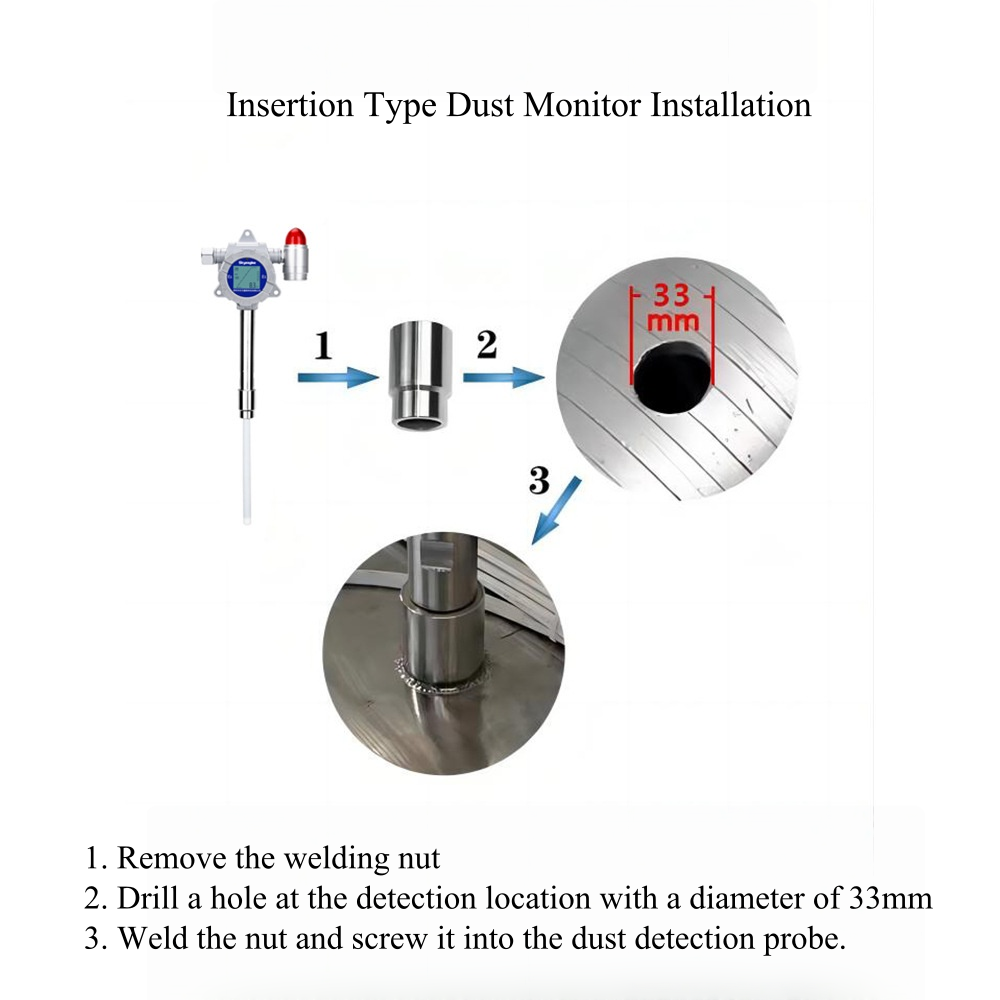

- Adopt an insertion design, no complex sampling pipeline system is required. Installation only requires opening an interface of appropriate size on the pipe or container.

- The installation and use are exactly the same as the three-wire pressure transmitter. On-site engineering and technical personnel can use it correctly without special training.

- The 4-20mA current output by the built-in integrated transmitter in the junction box is electrically isolated from the dust sensor probe to achieve safe signal transmission.

- The sensor body adopts an airtight connector design. Strictly prevent the leakage of the measured gas and the extrusion of the measuring electrode due to pressure. Ensure the safety of the transmitter and staff.

- Adopt special materials and protective design, which can withstand harsh working conditions such as high temperature, high pressure, high humidity, and corrosive.

- Standard three-wire 4-20mA current output, strong anti-interference capability, easy for long-distance signal transmission. No special requirements for signal transmission wires. The output current is linearly related to the dust concentration, which facilitates subsequent PLC data processing.

Specifications

| Dust | Including: dust, coal powder, flour, dust, smoke, graphite, manganese dioxide, quicklime and other particulate matter |

| Dust particle size range | Nominal 0.1μM~200μM, it can still be received outside the nominal range but the signal characteristics are a little different. |

| Operating environment temperature | -20℃~60℃ (electronic components) |

| Operating environment humidity | Humidity 90% |

| Operating environment protection | Protection level: IP66/NEMA4 aluminum alloy shell, suitable for installation in non-corrosive environment, stainless steel probe |

| Pipeline gas pressure | -0.1~1MPa |

| Pipeline gas flow rate | 1m/s~30m/s |

| Pipeline gas temperature | 0℃~250℃ (260℃-800℃ can be customized) |

| Pipeline outer diameter | 0.1m~4m |

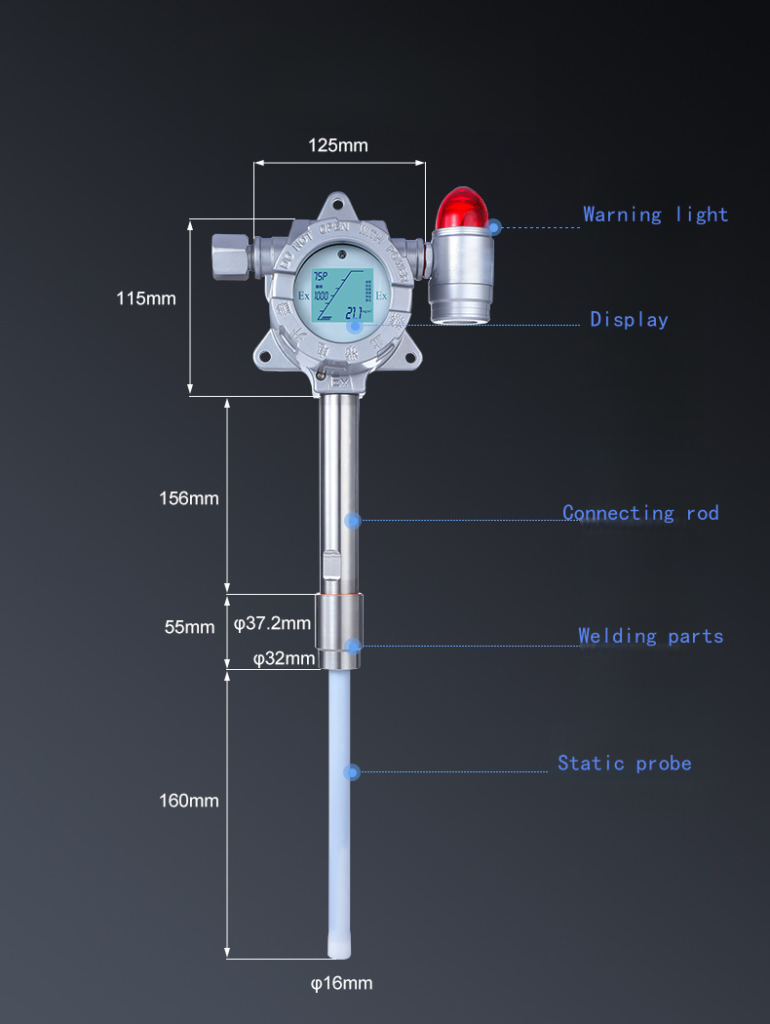

| Probe structure | The standard probe is φ16mm, length 100mm-1000mm, probe material: rare earth amorphous alloy, |

| Zero drift | (Time) Less than 1% of the range per year. |

| Zero drift | (Temperature) Less than 1% of the range within the specified temperature range. |

| Full scale drift | (Time) Less than 1% of the range per year |

| Full scale drift | (Temperature) Less than 1% of the range within the specified temperature range. |

| Line stability | All system components are made of high-stability electronic assemblies. |

| Noise resistance | All 50 or 60 Hz audio and harmonics are filtered out before the signal is received |

| Measurement range | 0-10mg/50mg/100mg/200mg/1000mg/30g/100g/m3 |

| Transmitter output mode | Two-wire 4-20mA (built-in isolator, explosion-proof and anti-interference) |

| Transmitter power supply | 24V (available in the range of 15V to 32V) |

| Measurement accuracy | ±5% |

| Probe length selection | Please select the probe length according to the formula, that is, D/3 ≤ L ≤ 2D/3 (where: D – pipe inner diameter, L – probe length) |

| Operating environment vibration | Maximum continuous oscillation, any direction, any frequency: RMS value 2g (20m/s²) |

| Operating environment electromagnetic field | Maximum value at 50 Hz = 60 A/m (equivalent to a 50 A T magnetic field within a 1 m × 1 m square electromagnetic coil). |

Triboelectric In-line Dust Monitor Working Principle

Triboelectric In-line Dust Monitor measures the electrostatic charge induction of dust particles passing through a fixed probe.

The dust particles and the probe induce electrostatic charge, which is amplified by the probe and transmitted to the monitoring control system. The size of the electrostatic charge is proportional to the flow rate of the dust particles.

The high-tech electronic circuit of this system converts this part of the charge into a control signal output. It activates the dust emission alarm and is used to continuously record the total amount or concentration of dust particles.

Under relatively stable combustion conditions (i.e., at the same emission point, the flow rate, temperature, pressure, humidity and smoke particle properties do not change much, less than ±90% of the change), this system can also be used for online monitoring of emission concentration (unit = mg/M3) after direct calibration.

Featured Applications

Triboelectric In-line Dust Monitor \ is widely used in various industrial applications, including steelmaking, power generation, petroleum, building materials processing, coal mining, cement manufacturing and packaging.

Typical uses include:

- Detection of bag filter bag damage.

- Powder material recovery, product delivery total monitoring.

- Monitoring of smoke emission concentration of boilers of various sizes and fuels.

1. Industrial production monitoring:

In industrial production such as mining, metallurgy, and power plants, Insertion Type Dust Monitor is used to monitor the dust concentration generated during the production process to ensure production safety and worker health.

In the raw material crushing, raw material grinding, clinker calcination, cement grinding and other links of cement production, dust concentration monitoring is crucial. Insertion Type Dust Monitor is designed for such high dust environments. The measurement range is 0-1000mg/m³, and the accuracy is ±2. It is an ideal choice for safe production in cement plants.

Monitoring of CO concentration in process gases such as blast furnace gas, converter gas, and coke oven gas in iron and steel metallurgy, as well as dust control in processes such as raw material processing, sintering, and coking, all require reliable plug-in detection equipment. Equipped with a high-temperature probe, it can withstand a medium temperature of 800°C.

2. Environmental protection:

Environmental monitoring departments use dust detectors to detect atmospheric dust and investigate pollution sources to assess environmental pollution and take corresponding measures.

3. Public safety:

In terms of municipal smoke monitoring, monitor the smoke content in urban air to provide data support for urban air quality management.

4. Scientific research:

The plug-in dust detector is used in filter material performance tests and other experiments that require on-site testing. It helps scientific researchers obtain accurate dust concentration data.

5. Labor health monitoring:

In the labor department of industrial and mining enterprises, by measuring the dust concentration at the production site, it ensures that the working environment meets health and safety standards and protects workers from dust hazards.

How Gas Detectors Work: 4 Key Sensor Types

7 Critical Gas Detector Calibration Errors to Avoid: An Expert Guide

5 Essential Factors for Choosing Multi Gas Detectors

What is a Combustible Gas Detector? And 5-Step Selection Guide

Choosing the right testing equipment is not only about meeting compliance requirements, but also about taking responsibility for enterprise safety production, employee health and environmental protection.

Sino-Inst is committed to providing customers with the most reliable dust and gas detection solutions. Our products have been successfully used in more than 300 countries and regions around the world. Whether it is a standard product or a special customization, Sino-Inst’s professional team will provide you with the best technical support and service guarantee.

Request a Quote

.png)