The TS-290 polarographic dissolved oxygen electrode monitors trace oxygen at extreme temperatures.Features include resistance to high-temperature steam disinfection (0-130 ℃) and sensitive PPB level measurement, capturing oxygen swings from 0.1ug/L to 20mg/L. 316L stainless steel shell and imported original PTFE breathable membrane make electrode anti-pollution, wear-resistant, and corrosion-resistant.

This works for desalinated water and boiler feedwater in thermal power plants with strict trace oxygen requirements. Electrochemical interactions between the cathode and anode yield linear current readings and a configurable temperature adjustment method for stable and reliable trace dissolved oxygen monitoring in high temperature and pressure conditions.

★★★★★

Feature

Measurement principle

The measurement principle of TS-120 dissolved oxygen sensor is based on the polarographic method (Clark-type diaphragm sensor).

It consists of a cathode and an anode connected by a conductive electrolyte. When an appropriate polarization voltage is applied between the cathode and anode, oxygen (O₂) is reduced at the cathode, while a corresponding oxidation reaction occurs at the anode. These electrochemical reactions generate a current that is proportional to the partial pressure of oxygen in the measured solution.

The specific reactions are as follows:

- Cathode reaction: O₂ + 2H₂O + 4e⁻ → 4OH⁻

- Anode reaction: 4Ag + 4Cl⁻ → 4AgCl + 4e⁻

Parameters

| Category | Specifications |

|---|---|

| Measurement Principle | Polarographic method (Clark principle) |

| Measurement Range | 0.1ug/L (ppb) – 20mg/L (ppm) |

| Operating Conditions | Measurement Temperature: 0-80℃; Sterilization Temperature: 0-130℃; Pressure: 0.6Mpa |

| Response Time | <90s (95% reduction at 25℃); <40s (95% reduction at 35℃) |

| Stability | Drift <1% per month (constant temperature and pressure) |

| Polarization Voltage | 600-750mV |

| Electrode Signal | 30-65nA at 25℃ (customizable) |

| Residual Current | <2% of full scale (room temperature signal in oxygen-free medium) |

| Temperature Compensation | PT1000, PT100, 2.252K, 22K (customizable) |

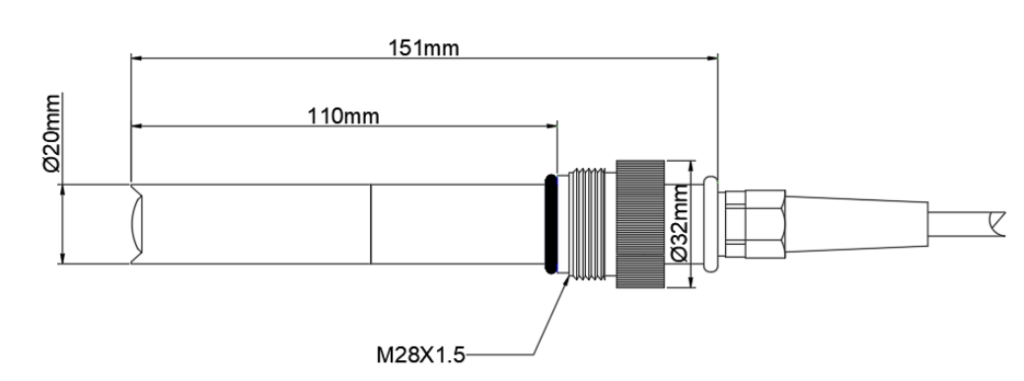

| Physical Parameters | Dimensions: Diameter 20mm; Insertion Depth: 70/150/220mm (customizable); Thread Interface: M28*1.5; Cable Length: Standard 5m (max. customizable to 30m) |

| Material | Housing: 316L stainless steel; Membrane: Imported PTFE breathable membrane |

| Electrode Composition | Cathode: Platinum (Pt); Anode: Silver (Ag); Electrolyte: Potassium chloride alkaline solution |

Core Highlights

- Measures PPB levels from 0.1 to 20 mg/L with minimal residual current and monthly drift, detecting trace dissolved oxygen fluctuations for desalination and furnace feedwater applications.

- Supports high-temperature steam disinfection (0-130 °C) and accurate measurement up to 80 °C for effective sterilization.

- Acid, alkali, and corrosion-resistant 316L stainless steel shell and robust, pollution-resistant imported PTFE breathable membrane prevent pollutants from adhering in industrial water bodies.

- High sensitivity and efficiency: <40s at 35 ℃ and <90s at 25 ℃, detecting dissolved oxygen concentration changes without waiting for steady data.

- The standard M28 * 1.5 threaded interface, changeable insertion depth requirements, and ability to be customized make it easy to replace the membrane cover, cheap to do daily maintenance, and cheap to run.

Featured Applications

- Thermal power plants: measuring trace dissolved oxygen in desalinated water, boiler feedwater, condensate water, etc., with high temperature and pressure resistance for power plant process environments.

- Power plant: Control trace oxygen levels in different water types to prevent oxygen corrosion and extend equipment life.

- Process water dissolved oxygen monitoring for chemical, pharmaceutical, and other businesses that need to sterilize things at high temperatures for production and quality control.

- High-end water treatment: Keep an eye on the amount of dissolved oxygen in ultrapure and high-purity water to make sure the quality is good.

Daily maintenance and precautions

Maintenance points

- When installing, choose matching protective sleeves or cable connectors to ensure that the threaded interface is tightly sealed and avoid water leakage.

- The connection between the sensor wire and the electrode is not waterproof, and waterproof treatment should be done to avoid moisture affecting signal transmission.

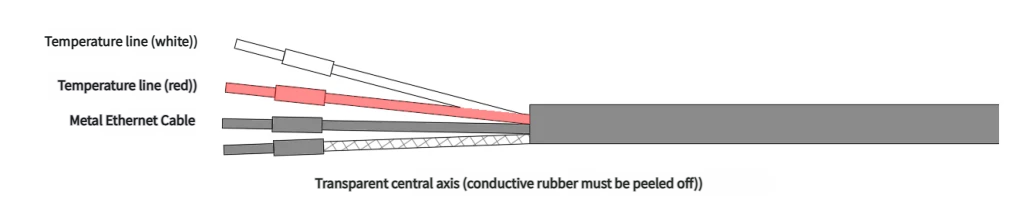

- When stripping the wire, it is necessary to peel off the metal mesh layer, thoroughly remove the conductive black skin on the outer layer of the transparent central axis, and there should be no additional contacts in the middle.

- Avoid sensor contact with sharp objects to prevent membrane damage; The installation location should be away from strong magnetic fields and mixers to ensure stable measurement.

- Before the first use, it is necessary to connect polarization with the host and complete zero and slope calibration according to the host calibration process to improve measurement accuracy.

Safety precautions

- Regularly check the condition of the breathable membrane. If there is mechanical damage or serious contamination, replace the membrane cover and replenish the electrolyte in a timely manner.

- If there are visible dirt or attachments on the surface of the platinum cathode, gently polish it with 1200 # metallographic sandpaper, then rinse it with pure water and absorb the surface water droplets; When brown deposits appear on the silver anode, use 700 # metallographic sandpaper to polish until a shiny silver surface is exposed.

- When stored for a long time, after filling the electrolyte, an appropriate amount of distilled water should be added to the electrode cap to keep the membrane moist; If not in use for more than 6 months, rinse the electrode core and membrane sleeve, drain the electrolyte, and store.

- Avoid touching the surfaces of platinum cathode and silver anode with hands to prevent oil stains from affecting electrode characteristics; Before cleaning the electrodes, turn off the instrument power or disconnect the cable connection.

Electrode diagram illustration

- After opening the packaging, check for mechanical damage to the electrode cap and electrode body;

- Select the corresponding electrode sleeve or cable head for installation according to different electrodes;

- The connection between the electrode wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

Wire stripping instructions

Attention:

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first peel off the metal mesh layer into the metal mesh as shown in the picture, and be sure to remove the conductive black skin of the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 7 portable combustion analyzer Tested

The TS-290 high-temperature PPB grade dissolved oxygen electrode is now the standard for tracking high-temperature and trace dissolved oxygen in industry. It is very accurate, can handle high temperatures, doesn’t corrode, and doesn’t pollute. It can always give correct data, even when things are hard, whether it’s checking the water quality at a thermal power plant or managing the process of making high-end goods. It’s simple to keep up and can be changed on-site to fit different wants.

We provide professional technical support, including installation guidance and calibration suggestions. If you have any questions about product selection, customization, or use, please feel free to contact us at any time. Make TS-150 electrode your reliable partner for water quality monitoring!

Request a Quote

.png)