For complex water quality issues, the room-temperature TS-120 dissolved oxygen electrode uses Clark type diaphragm polarography. The primary benefits of 316L stainless steel shell and membrane cap and steel mesh reinforced composite breathable membrane are no membrane and electrolyte replacement, good anti-pollution, wear, and corrosion resistance. Current from the cathode-anode electrochemical process is proportional to water oxygen partial pressure. The robust and consistent sensing support for online dissolved oxygen analysis in water quality treatment, wastewater monitoring, chemical production, and other fields captures oxygen concentrations as low as 40ppb.

★★★★★

Feature

Measurement principle

The measurement principle of TS-120 dissolved oxygen electrode is based on the polarographic method (Clark-type diaphragm sensor).

It consists of a cathode and an anode connected by a conductive electrolyte. When an appropriate polarization voltage is applied between the cathode and anode, oxygen (O₂) is reduced at the cathode, while a corresponding oxidation reaction occurs at the anode. These electrochemical reactions generate a current that is proportional to the partial pressure of oxygen in the measured solution.

The specific reactions are as follows:

- Cathode reaction: O₂ + 2H₂O + 4e⁻ → 4OH⁻

- Anode reaction: 4Ag + 4Cl⁻ → 4AgCl + 4e⁻

Parameters

| Category | Specifications |

|---|---|

| Measurement Principle | Polarographic method (Clark-type diaphragm sensor) |

| Measurement Range | Detection limit <40ppb dissolved oxygen |

| Response Time | <2 minutes (90% reduction of oxygen content at 25℃) |

| Operating Conditions | Temperature: 0~60℃; Pressure: 0~4bar |

| Electrode Signal | 20~80nA at 25℃ (customizable per customer requirements) |

| Temperature Compensation | Thermistor resistance (customizable) |

| Residual Current | <2% of full scale (room temperature signal in oxygen-free medium) |

| Membrane Material | Steel screen-reinforced PTFE + Polysiloxane composite membrane |

| Physical Parameters | Dimensions: Diameter 12mm, Length 120mm; Thread Interface: PG13.5 (customizable); Cable Length: Standard 5m (max. customizable to 30m) |

| Housing Material | 316L stainless steel (shell + membrane cap) |

Core Highlights

- This 316L stainless steel shell and membrane cap can handle both raw and treated wastewater because it doesn’t let impurities and pollutants through, doesn’t rust, and can handle acid and alkali. It can also breathe.

- Maintenance-free design: The membrane and solution don’t need to be replaced, which saves money and time in the future and lets the experiment go on all the time.

- The sensor is very sensitive and reliable. It has a 40ppb detection limit for changes in dissolved oxygen at 25 °C, a response time of less than two minutes, and a residual current of less than 2%. The data is also always the same.

- With a 12mm diameter, 120mm length, and a PG13.5 threaded interface, this cable is very flexible and great for small installation sites. The cable can be switched out up to 30 meters for on-site setup.

Featured Applications

- As part of wastewater treatment, you should check the amount of dissolved oxygen in sewage from factories, homes, and biochemical reaction tanks.These tanks are good for streams with a lot of impurities because they don’t rust or get dirty.

- In the chemical sector, they check the amount of free oxygen in the process water used to make chemicals and fertilizer and make sure it can handle both acidic and basic conditions.

- Dissolved oxygen levels are checked in real time in ponds with fish and shrimp. Stainless steel doesn’t let germs in, which keeps aquaculture safe.

- Checking the quality of the water: checking the hydrology and the quality of the pool water to make sure the system works correctly and lasts a long time.

Daily maintenance and precautions

Maintenance points

- When installing, choose matching protective sleeves or cable connectors to ensure that the threaded interface is tightly sealed and avoid water leakage.

- The connection between the electrode wire and the electrode is not waterproof, and waterproof treatment should be done to avoid moisture affecting signal transmission.

- When stripping the wire, it is necessary to peel off the metal mesh layer, thoroughly remove the conductive black skin on the outer layer of the transparent central axis, and there should be no additional contacts in the middle.

- Avoid electrode contact with sharp objects to prevent membrane damage; The installation location should be away from strong magnetic fields and mixers to ensure stable measurement.

- Before the first use, it is necessary to connect polarization with the host and complete zero and slope calibration according to the host calibration process to improve measurement accuracy.

Safety precautions

- Every three to six months, wash the surface with clean water to get rid of anything stuck on it. This keeps the membrane’s water moving.

- Clean, seal, and store the electrode somewhere dry if you’re not going to use it for a while. The barrier won’t break down because of this.

- It is important to check the cable link and make any changes that are needed to make sure the signal gets through if the test data changes.

- Heavy acid or alkaline liquids can damage electrodes over time, so don’t leave them in them for too long.

Electrode diagram illustration

- After opening the packaging, check for mechanical damage to the electrode cap and electrode body;

- Select the corresponding electrode sleeve or cable head for installation according to different electrodes;

- The connection between the electrode wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

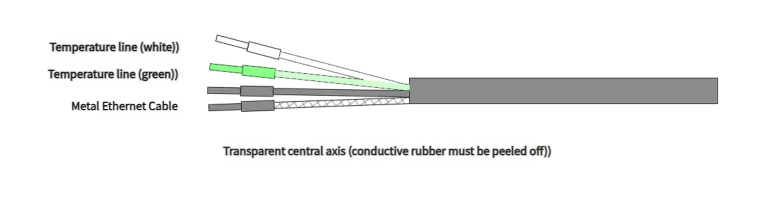

Wire stripping instructions

Attention:

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first peel off the metal mesh layer into the metal mesh as shown in the picture, and be sure to remove the conductive black skin of the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 7 portable combustion analyzer Tested

The TS-120 dissolved oxygen electrode, with its corrosion and pollution resistance, maintenance free design, and sensitive and stable measurement performance of 316L stainless steel, has become the preferred equipment for monitoring dissolved oxygen in harsh water quality environments. Whether it is high impurity wastewater, corrosive chemical environments, or conventional water quality monitoring scenarios, it can provide accurate and reliable data support, greatly reducing maintenance costs and operational difficulties.

We provide professional technical support, including installation guidance and calibration suggestions. If you have any questions about product selection, customization, or use, please feel free to contact us at any time. Make TS-150 electrode your reliable partner for water quality monitoring!

Request a Quote

.png)