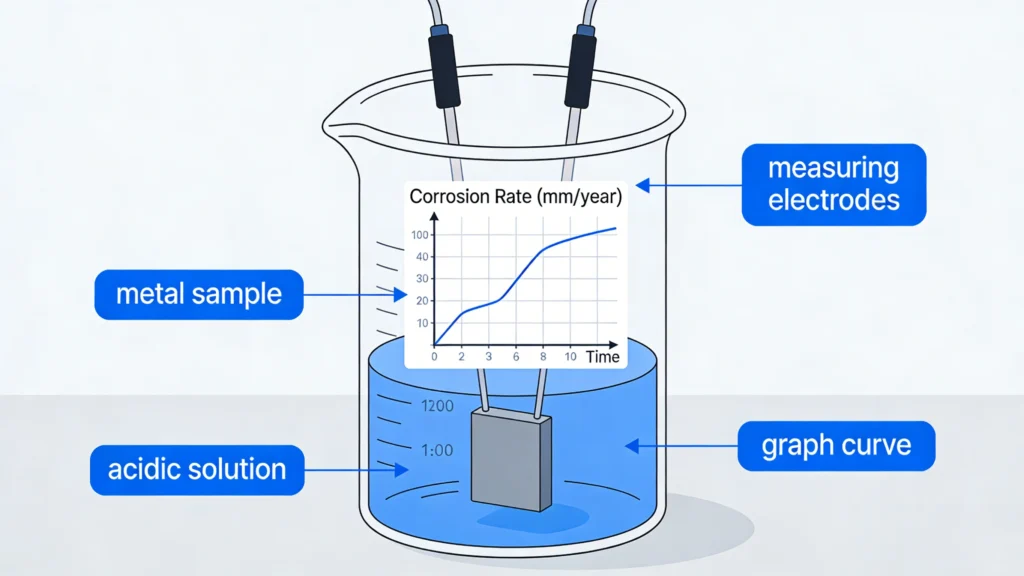

The Sino-Inst corrosion rate product consists of an online corrosion rate meter (measurement and control core) and an online corrosion rate electrode (sensing core), which enables real-time, continuous and accurate monitoring of the corrosion rate of industrial equipment, avoiding equipment failures, production interruptions and other problems caused by corrosion from the source, and safeguarding industrial production safety.

★★★★★

Quick product navigation

What is corrosion rate?

Corrosion rate is the degree of damage caused by chemical/electrochemical corrosion of metal materials in a specific medium, temperature, pressure, and other working conditions per unit time. It is commonly measured in millimeters per year (mm/a) and miles per year (mil/a), and is a core indicator for measuring the corrosion status and aging rate of industrial metal equipment.

Why is it necessary to monitor corrosion rate?

Traditional offline detection suffers from data lag and is unable to detect corrosion risks in a timely manner; Online detection can capture changes in corrosion rate 24 hours a day, provide early warning of equipment corrosion hazards, and provide quantitative data support for corrosion inhibitor addition, equipment maintenance and replacement, and process parameter optimization. Ultimately, it reduces equipment operation and maintenance costs, ensures continuous production safety, and meets the compliance requirements of industrial environmental protection and safety production.

Core role of online monitoring corrosion rate

- Real time warning: Continuous monitoring of corrosion data, automatic alarm when exceeding standards, timely avoidance of sudden risks such as equipment leakage and damage;

- Scientific operation and maintenance: Record corrosion data trends to provide a basis for equipment maintenance and replacement plans, avoiding excessive maintenance or maintenance deficiencies;

- Cost reduction and efficiency improvement: Accurately adjust process parameters and chemical dosage based on corrosion data to reduce chemical waste and downtime losses;

- Intelligent integration: supports 4-20mA/RS485 signal output, can be connected to the factory control system, and achieve remote centralized monitoring;

- Stable adaptation: Industrial grade design, temperature and pressure resistance, pollution resistance, and can operate stably under various complex industrial conditions.

Typical application scenarios

Widely applicable to various industrial fields with corrosion risks of metal equipment, the core scenarios include:

- Thermal power industry: corrosion monitoring of equipment such as boilers, condensers, and circulating water pipelines;

- Petrochemical industry: monitoring of reaction vessels, heat exchangers, and pipelines for transporting crude oil/chemical media;

- Oil and gas extraction: corrosion monitoring of oil and gas well pipelines, gathering and transportation pipelines, and separation equipment;

- Metallurgical industry: acid pickling tank, smelting circulating water pipeline, electroplating equipment monitoring;

- Water treatment/environmental protection: corrosion monitoring of industrial wastewater treatment pipelines and storage tanks;

- Ocean engineering: seawater desalination equipment, metal components of offshore platforms, monitoring of ship pipelines.

Core Product System

Online Corrosion Rate Meter “Measurement and Control Core”

Industrial grade measurement and control terminal, based on electrochemical principles to process electrode signals, real-time display of corrosion rate and medium temperature, supporting threshold alarm, data storage, 4-20mA/RS485 output, Chinese and English menus, disk/wall mounted dual installation, IP65 protection, suitable for various industrial conditions, is the core control unit of corrosion monitoring.

Core advantages: precise measurement and control with temperature compensation, intelligent linkage alarm, data traceability, easy integration with central control, and convenient operation.

Online corrosion rate electrode “sensing core”

Using linear polarization/resistance method, the working electrode is made of the same material as the industrial equipment and directly contacts the medium to capture corrosion signals and convert them into electrical signals for transmission; Built in thermistor (temperature compensation), industrial grade corrosion-resistant package, standard installation size, temperature resistance from 0-80 ℃, anti pollution, stable signal.

Core advantages: sensitive sensing, durable material, temperature adaptation, flexible installation, convenient maintenance, providing accurate raw signals for instruments.

Technical Support

How to Raise pH in Pool: The Chemical Guide & The Automated Solution

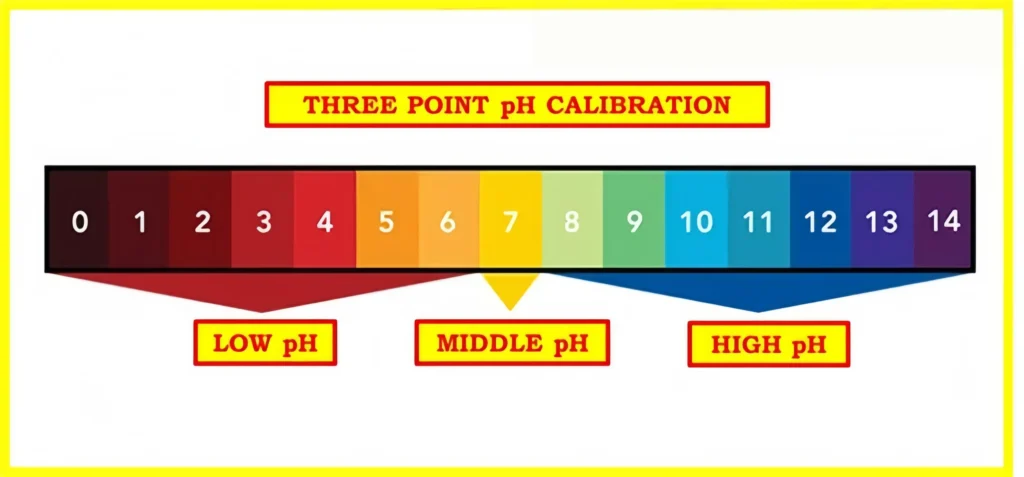

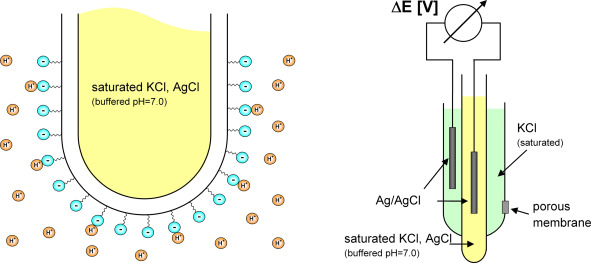

How to Calibrate pH Meter: A Step-by-Step Guide for Accurate Readings

Top 5 Heavy-Duty Plastic pH Electrodes for Wastewater (2026)

The online corrosion rate meter and electrode integrated monitoring system lets you monitor corrosion in a measurable way and avoids problems with offline detection. Industrial-grade chain sensing, measurement, and control can handle dangerous operational scenarios. Using scientific data, it predicts corrosion, protects tools and production, and makes industrial processes work better. Controlling corrosion, lowering costs, and increasing efficiency in the workplace are all very important.

Request a Quote

.png)