Water turbidity data can be safely converted by ISO7027-based DSS-230-10M medium range turbidity sensors employing scattered light detection and an 860 nm laser light source. With the gadget, surface water, industrial processes, and water and sewage treatment facilities can all benefit from immersion installation, IP68 protection and sealing, and online monitoring. 0–1000 NTU is covered. It is easy to integrate because of its small size, slanted light window design that prevents bubble attachment, straightforward construction, and reliable monitoring of various turbidity water bodies.

★★★★★

Features

- Compact size, convenient for system integration;

- Simple structure, easy to clean and maintain;

- Sloping light window, bubbles are not easily attached;

- Sealed structure, resistant to deep water or high pressure;

- IP68 protection, can be installed in a modular manner.

Working Principle

The sensor emits a laser beam into the measured liquid, and the suspended particles in the measured liquid produce scattered light

The receiver detects the scattered light intensity and converts it into turbidity value based on the calibration table.

Parameters

| Category | Specifications |

|---|---|

| Measurement Principle | 860nm laser light source, scattered light intensity conversion method (complies with ISO7027 standard) |

| Range & Accuracy | Range: 0~1000NTU; Accuracy: ±5% or ±0.5NTU (whichever is larger), based on Formazin primary standard solution at 25℃ |

| Core Performance | Detection limit: 0.05NTU; Resolution: 0.01NTU; Repeatability: ≤1%; Zero drift: ≤1.5%; Indication stability: ≤1.5%; Response time (T90): ≤120s |

| Working Conditions | Water sample temperature: -5~45℃; Pressure: 0.6MPa; Flow rate: 100~1000mL/min (recommended 500mL/min) |

| Power & Signal | Power supply: DC 9-28V; Peak power: 5W; Interface: RS485 Modbus-RTU + 4-20mA dual interface |

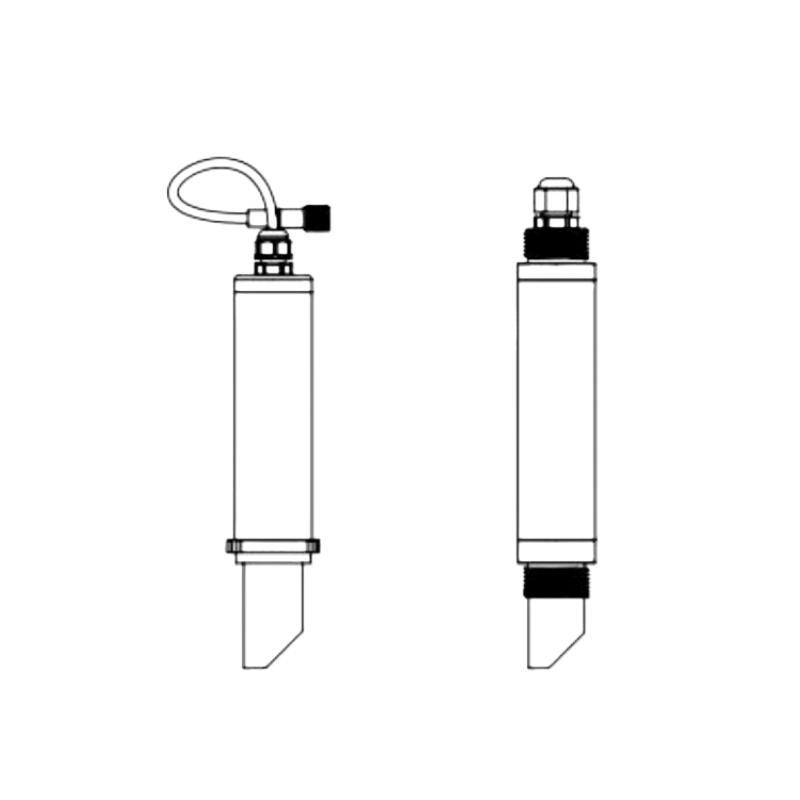

| Physical Specifications | Material: ABS + POM plastic; Dimension: 182mm×Φ32mm (snap-on version) / 203mm×Φ32mm (threaded version); Protection class: IP68 |

| Calibration Methods | Factory calibrated (default curve); Single-point calibration, Formazin two-point calibration, 2-6 point custom calibration |

Core Highlights

- The 0.01NTU precision ensures accurate data across the 0~1000NTU range, from low tap water to heavy industrial wastes.

- Adapt to complex environments: the sealed structure can endure high pressure, IP68 protection may be put in deep water, and the operating temperature is -5 to 45 °C.

- Double installation with buckle/thread (NPT 3/4 thread) allows cleaning and upkeep easy and effective. The slanted light window is hard to adhere bubbles to.

- Multiple-mode calibration, dual RS485+4-20mA ports, the default Modbus protocol, and interoperability with many monitoring systems are examples of flexible calibration and communication.

Featured Applications

- Municipal water affairs: monitoring of turbidity in raw water/effluent from water plants, control of inlet and outlet water quality in sewage treatment plants;

- Environmental monitoring: online screening of turbidity in surface water, lakes, and reservoirs, emergency monitoring of pollution incidents;

- Industrial production: Control of process water turbidity and monitoring of circulating water quality in industries such as chemical, metallurgical, and papermaking;

- Other scenarios: monitoring of wastewater discharge in the park, monitoring of turbidity in aquaculture water bodies.

Daily maintenance and precautions

Installation and operation points

- Installation requirements: The buckle plate is fixed with M3 screws on the installation ring and inserted into the circulation pool. It is then fixed by rotating clockwise 90 °; The threaded version is installed on the bracket through NPT 3/4 thread, with a minimum distance of 30cm from the pool wall.

- Wiring specifications: 4-core wire (without 4-20mA): red=24V+, black=24V -, green=485A, yellow=485B; 6-core wire (including 4-20mA): add purple/brown (4-20mA+), white (4-20mA -), turn off the power before wiring.

- Communication parameters: default Modbus slave address 3, baud rate 9600, data bit 8, stop bit 1, no checksum.

Daily maintenance and troubleshooting

- Points for maintenance: Check the smoothness of the water coming in and going out on a regular basis; when the water quality is low, clean the sensor light window and circulation pool more often; Check to see if the measurement is correct, and if it isn’t, make changes.

- If the RS485 communication doesn’t work, reconnect the signal line. To keep equipment from leaking, the water pressure shouldn’t go over 0.6 MPa. If a low turbidity value shows that the light source is broken, get in touch with technical support.

Technical Support

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 7 portable combustion analyzer Tested

The DSS-230-10M is great for reading medium turbidity because it has a wide range, is reliable, and is easy to use. It reliably checks the safety of municipal water and the purity of water used in industry processes. It does this by giving accurate information, being flexible, and being easy to use and keep up to date.

It is easy to connect to monitoring systems because it can be set up in a number of different ways and uses standard communication methods. Users can quickly reach their goals for managing water quality.

Request a Quote

.png)