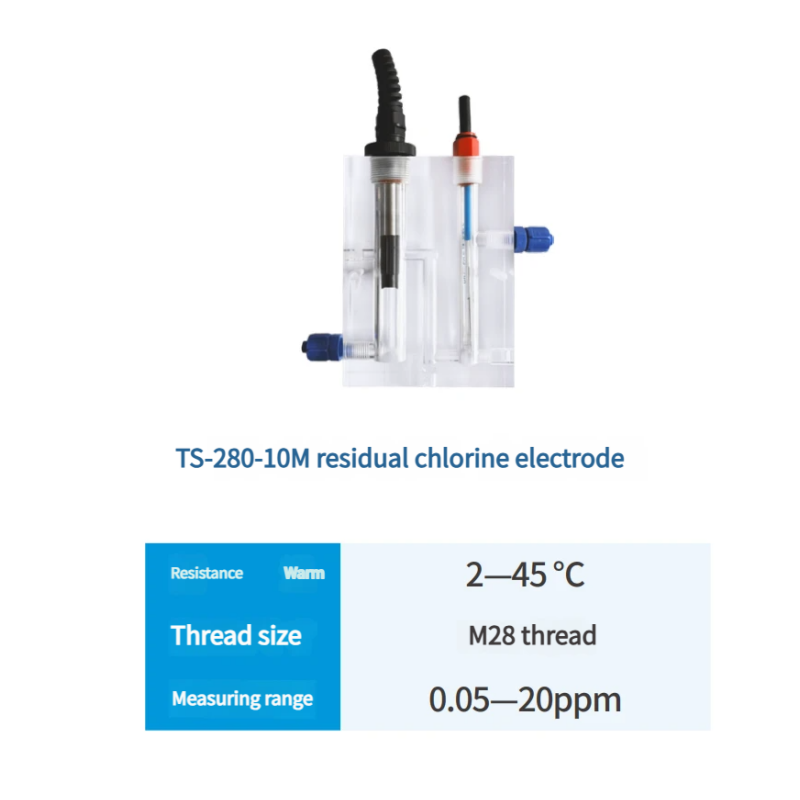

Smart online residual chlorine controller TC-2200 tracks various parameters. Provided are the PP-68 probe flow channel, TS-280-10M residual chlorine electrode, and GRT1120-10M pH electrode. Main features are precision, ease of use, and four-parameter simultaneous measurement.It measures residual chlorine, HOCl, pH, and temperature.

Imported components and polarographic analysis technology enable manual/automatic dual compensation, isolation signal output, and intelligent alert for drinking water, circulating water, and membrane treatment process inflow. In water supply, swimming pools, chemical industry, and pharmaceuticals, it provides comprehensive data for water quality disinfection monitoring.

★★★★★

Features

Specifications

| Category | Specifications |

|---|---|

| Measuring Parameters | Residual Chlorine, Hypochlorous Acid (HOCl), pH, Temperature |

| Measuring Range | Residual Chlorine: 0-20.00 mg/L; HOCl: 0-10.00 mg/L; pH: 0-14.00; Temperature: 0-60℃ |

| Measuring Accuracy | Residual Chlorine/HOCl: ±1% or ±0.01 mg/L; pH: ±0.02 pH; Temperature: ±0.5℃ |

| Resolution | Residual Chlorine/HOCl: 0.001 mg/L (low range) / 0.01 mg/L (high range); pH: 0.01 pH; Temperature: 0.1℃ |

| Compensation Functions | Manual/automatic pH compensation (0-14); Manual/automatic temperature compensation (0-60℃) |

| Signal Output | Photoelectrically isolated 4-20mA output (load ≤350Ω); Optional RS485 (ModBus RTU) communication |

| Alarm Output | 2 groups of normally open contact relays (3A/220VAC), high/low point alarm with adjustable hysteresis |

| Operation & Display | Chinese menu interface, large dot-matrix LCD backlight display, 5 display modes, simultaneous multiparameter presentation |

| Safety & Protection | Password protection (initial password: 1000), power-off protection ≥10 years, watchdog function to prevent crashes |

| Physical Dimensions | Overall Dimensions: 96×96×115mm (H×W×D); Cutout Size: 91×91mm (H×W) |

| Power Supply & Consumption | Power Supply: AC220V±10% (50/60Hz); Power Consumption: ≤7W |

| Operating Environment | Temperature: 0-60℃; Humidity: ≤90%RH (no condensation) |

| Standard Configuration | TC-2200 Main Unit, TS-280-10M Residual Chlorine Electrode (with spare membrane head + electrolyte), GRT1120-10M pH Electrode (with 3 types of standard solutions), PP-68 Flow Cell, Fixing Accessories, Special Signal Cable, Operation Manual |

Standard Configuration

- Host:TC-2200

- Residual chlorine electrode: TS-280-10M

- PH electrode: GRT1120-10M

- Electrode flow channel: PP-68

Core Highlights

- Four parameter synchronous monitoring: simultaneous measurement of residual chlorine, hypochlorous acid pH、 Temperature, no need for additional equipment, multi-dimensional control of water disinfection status, especially suitable for membrane treatment process inflow monitoring.

- Four parameter synchronous monitoring: simultaneous measurement of residual chlorine, hypochlorous acid pH、 Temperature, no need for additional equipment, multi-dimensional control of water disinfection status, especially suitable for membrane treatment process inflow monitoring.

- Dual compensation is better since it enables both manual and automated pH and temperature adjustment. This means it can handle varied situations where the pH and temperature of the water change, making sure that measurements are correct even when the conditions are complicated.

- Flexible expansion and protection: optional RS485 communication docking with central control system, photoelectric isolation output anti-interference; The relay hysteresis can be adjusted to avoid frequent on-off, and the watchdog function prevents instrument crashes.

Featured Applications

- Drinking water treatment plant/pipeline network: Monitor the residual chlorine and hypochlorous acid content in the factory water and distribution pipeline network to ensure the disinfection effect and safe transportation of drinking water.

- Cooling circulating water system: Monitoring residual chlorine in industrial circulating water to prevent chlorine from corroding equipment or breeding microorganisms, ensuring stable operation of the system.

- Reverse osmosis membrane treatment process: precise monitoring of residual chlorine in the treated water to prevent damage to membrane components and extend equipment service life.

- Swimming Pool/Commercial Water Purification: Synchronized monitoring of residual chlorine and pH in swimming pools, hot springs, and commercial water purification equipment to ensure safe and compliant water quality.

- After cleaning, keep an eye on the low chlorine level to make sure the environment is safe and stop secondary contamination.

Daily maintenance and precautions

Installation and usage precautions

- Installation should avoid high temperature, high humidity, corrosive environments, and direct sunlight to ensure IP65 protection. The working environment temperature should be controlled between 0-50 ℃.

- The transmission of electrode signals must use dedicated cables and cannot be replaced by ordinary wires. When wiring, distinguish WE, CE, and RE terminals to avoid misconnection.

- It is recommended to supply power separately and not share it with equipment such as dosing machines and mixers to reduce power surge interference and ensure signal stability.

- Zero point calibration requires chlorine-free distilled water, while slope calibration requires stable water samples for 15 minutes and laboratory data adjustment without chemicals.

- To prevent overload damage and preserve the instrument interface, an auxiliary relay with suitable current resistance should be configured when the relay is linked to external equipment.

Key daily maintenance points

- Regularly clean the electrode membrane to avoid dirt adhesion, and do not use filter paper to wipe the membrane head to prevent damage; Replace or add electrolyte to the residual chlorine electrode every 6 months.

- It is recommended to perform calibration once a month (pH two-point calibration+residual chlorine zero point/slope calibration), which can be shortened to once every two weeks for complex water quality scenarios.

- Before long-term discontinuation, the electrode should be cleaned thoroughly, the residual chlorine electrode should be covered with a protective cap, and the pH electrode should be soaked in standard solution to prevent the membrane head from drying up.

- If there is a large deviation in the measurement data, first check whether the electrode membrane head is damaged and whether the electrolyte is dry. If necessary, replace the membrane head or electrolyte and re calibrate the polarization.

Technical Support

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 7 portable combustion analyzer Tested

The TC-2200 multi parameter online residual chlorine controller is the ideal water disinfection monitoring solution due to its four-parameter synchronous monitoring, high precision and stability, and easy operation. It can meet multi-dimensional monitoring needs for drinking water, industrial circulating water, membrane treatment, and commercial water purification with complete standard setups and minimal maintenance costs to ensure water quality safety.Water quality monitoring is efficient, accurate, and worry-free with TC-2200. Controlling the water quality will be simpler thanks to our expert technology and committed service.

Request a Quote

.png)