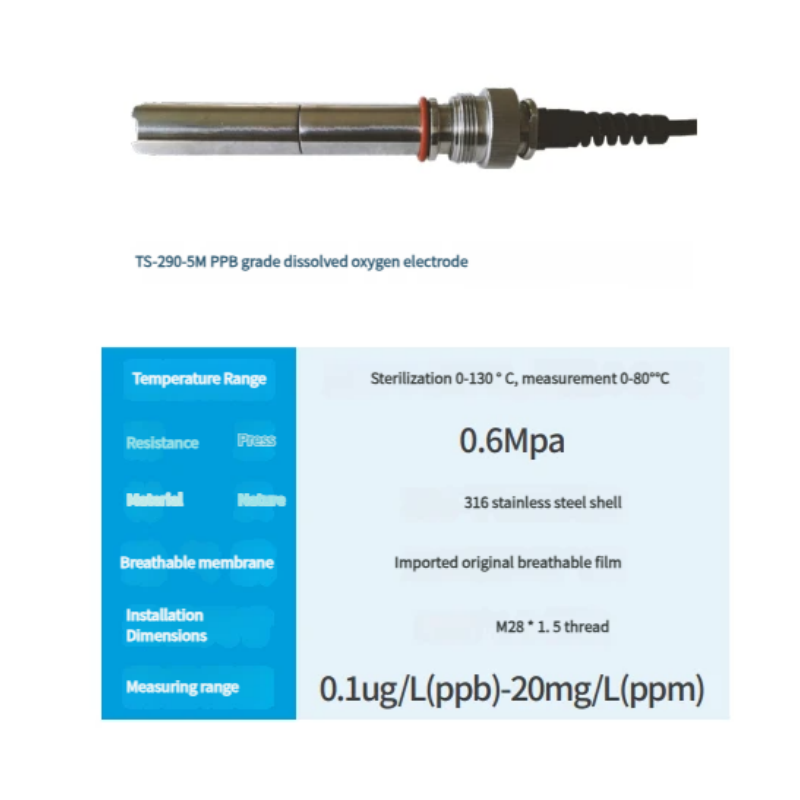

The RD-2082 smart online monitoring device monitors ultra-low dissolved oxygen. The device measures DO levels and temperature from 0-100.0 μ g/L to 0-20.00 mg/L, including an automated switch from PPB to PPM. Due to its fully Chinese display interface, numerous intelligent functions, stable communication protocols, and TS-290-5M PPB grade dissolved oxygen electrode and SS-208LT stainless steel flow channel, the device is suitable for thermal power generation, the chemical industry, pharmaceuticals, and tap water, especially for ultra-low dissolved oxygen monitoring like boiler feedwater and condensateF

★★★★★

Features

Specifications

| Category | Specifications |

|---|---|

| Measurement Range | Dissolved Oxygen (DO): 0~100.0μg/L (ppb), 0~20.00mg/L (ppm) (automatic switching)Temperature: 0~99.9℃ (measurement), 0~99.9℃ (temperature compensation range) |

| Measurement Accuracy | DO: ±1.0% FS (μg/L), ±0.5% FS (mg/L)Temperature: ±0.5℃ |

| Resolution | DO: 0.1μg/L, 0.01mg/LTemperature: 0.1℃ |

| Stability | ±1.0% FS |

| Temperature Compensation | Automatic (NTC), reference temperature: 25℃ |

| Response Time | <60 seconds (98% of final value at 25℃), <20 seconds (98% of final value at 37℃) |

| Signal Output | 0~20mA or 4~20mA isolated output (software selectable), maximum load resistance: ≤750Ω |

| Communication Interface | RS485/RS232 (optional), supports Modbus-RTU and ASCII communication protocols |

| Alarm Output | Relay output: 10A/220VAC |

| Power Supply | AC220V±10%, 50±1Hz |

| Physical Parameters | Dimensions: 146×146×104mm (H×W×D)Cutout Size: 138×138mm (H×W)Weight: 0.8Kg (secondary meter)Protection Class: IP65 |

| Operating Environment | Ambient Temperature: -20℃~50℃Relative Humidity: 0%~95%RH (non-condensing) |

| Pipe Connection | Hard/soft pipe with outer diameter: Φ8, Φ10, Φ12mm |

Standard Configuration

- Host: RD-2082

- Dissolved oxygen electrode: TS-290-5M

- Stainless steel circulation channel: SS-208LT

Core Highlights

- Ultra-high resolution, automatic changeover of PPB/PPM range, ultra-low concentration range (≤ 10 μ g/L), and ± 1.0% FS measurement accuracy support difficult circumstances like thermal power generation.

- Intelligent data-driven management: automatically stores data every 5 minutes, records historical data for 3 months, supports historical curve query and timed fixed-point traceability; built-in notepad, records 200 operations and alarm events for easy management and traceability.

- Flexible calibration and maintenance: supports one-point, slope, two-point, and manual zero/slope input, so it can work in diverse situations on site. It is easy to maintain the electrodes, replace the electrolyte and membrane, and the polarization time is short.

- Stable and compatible: IP65 protection for severe industrial environments; Modbus RTU/ASCII dual communication protocol for flexible interface with higher computers and PLC systems; load resistance < 750 Ω for stable signal transmission.

Featured Applications

- Thermal power generation: To keep equipment from rusting, you need to keep an eye on the ultra-low dissolved oxygen levels in the boiler feedwater and condensate all the time.

- Chemical industry: Control of low dissolved oxygen concentration in precision chemical reaction processes to ensure product quality.

- Pharmaceutical industry: Dissolved oxygen testing of pharmaceutical production water meets GMP standards.

- Tap water industry: monitoring of dissolved oxygen in drinking water sources and pipeline water to ensure water quality safety.

Daily maintenance and precautions

Maintenance points

- Electrode maintenance: Calibrate regularly (1-3 months), clean with neutral detergent when pollution is severe, and avoid using strong acids and alkalis; When not in use for a long time, it needs to be soaked in a specialized protective solution.

- Instrument maintenance: Keep the casing clean and avoid direct sunlight and corrosive environments; Check the relay contacts and wiring terminals once a year to prevent oxidation.

- Cable maintenance: Avoid pulling or bending cables. Special shielded wires should be used to extend cables, and the length should not exceed 30 meters.

Safety precautions

- Before installation and wiring, the power must be disconnected and operated by professionals to avoid the risk of electric shock.

- When connecting a relay to high-power equipment, an additional intermediate relay needs to be installed to prevent contact overload damage.

- If there is surge interference in the power supply, an independent power supply should be provided for the controller, separate from the power supply of equipment such as the dosing machine and mixer.

- The electrode installation must be well sealed with waterproofing, and it is strictly prohibited for water to enter the inside of the electrode or the wiring terminals, otherwise it may cause short circuit faults.

Technical Support

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 7 portable combustion analyzer Tested

The RD-2082 online dissolved oxygen controller is tailored for industrial grade ultra-low dissolved oxygen monitoring scenarios, with “ultra-low concentration precise measurement and intelligent data management” as its core. From thermal power generation to precision chemical engineering, from data storage to communication compatibility, we fully meet the monitoring needs of harsh working conditions. Paired with PPB grade specialized electrodes and stainless steel flow channels, a complete ultra-low dissolved oxygen monitoring solution is formed to assist users in controlling core process parameters and reducing equipment losses.

Request a Quote

.png)