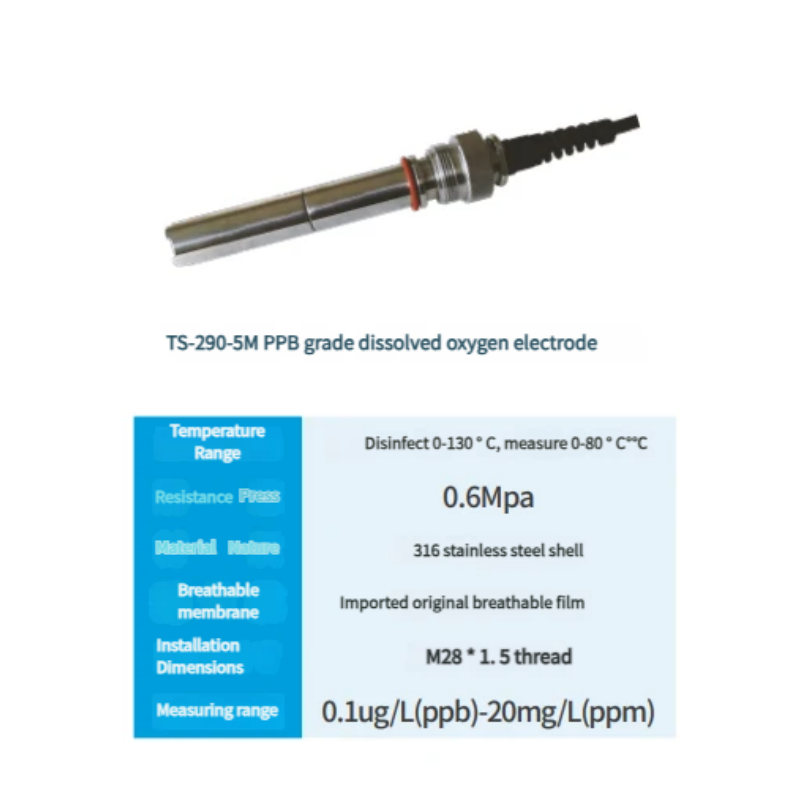

The high-tech online controller A20DO-PPB tracks very low dissolved oxygen levels. It measures ppb and ppm. It accurately measures temperature and dissolved oxygen levels (0.1 μ g/L (ppb) to 20.00mg/L (ppm). The gadget offers numerous temperature corrections, programmable relays, a signal output, and free English and Chinese interface switching. For accurate dissolved oxygen measurements in thermal power plants, boiler feedwater, condensate, high-end fermentation, and other applications, it is ideal. Electrodes are TS-290-5M PPB grade and flow channels are SS-208LT stainless steel. It always tracks ultra-low dissolved oxygen.

★★★★★

Features

Specifications

| Category | Specifications |

|---|---|

| Measurement Range | Dissolved Oxygen (DO): 0.1μg/L (ppb) ~ 20.00mg/L (ppm)Temperature: 0 ~ 130℃ (sterilization), 0 ~ 80℃ (measurement); temperature compensation range: 0 ~ 130℃ |

| Measurement Accuracy | ±1.0% F.S |

| Resolution | DO: 0.1μg/L (ppb), 0.01mg/L (ppm)Temperature: 0.1℃ |

| Temperature Compensation | Dual modes: Automatic (PT1000/NTC10K) / Manual |

| Signal Output | 4~20mA isolated output, maximum load resistance: ≤500Ω; optional RS485 Modbus RTU communication |

| Alarm Output | 3 groups of normally open contact relays (3A/250VAC), supporting high/low point alarm; 1 set of electrode automatic cleaning contact |

| Power Supply | Optional AC220V or DC24V; power consumption: ≤7W |

| Physical Parameters | Dimensions: 144×144×115mm (H×W×D)Cutout Size: 138×138mm (H×W)Mounting Type: Panel-mounted, Wall-mounted (dual modes) |

| Operating Environment | Ambient Temperature: 0~50℃Relative Humidity: ≤85%RH (no strong magnetic interference) |

Standard Configuration

- Host: A20DO-SA1-PPB

- Dissolved oxygen electrode: TS-290-5M

- Stainless steel circulation channel: SS-208LT

Core Highlights

- PPB accuracy: 0.1 µ g/L ultra-high resolution, ± 1.0% F.S measuring accuracy, perfect for water with very little dissolved oxygen, like boiler feedwater and condensate water.

- Wide temperature range: The electrode can clean at 0 to 130 °C, measure at 0 to 80 °C, make up for 0 to 130 °C, and handle changes in temperature in tough working conditions.

- When you use isolation technology and digital filtering (5/10/20 second mean possible) on the 4-20mA output, sending data in the industrial field is more reliable.

- Flexible installation: allows for putting on panels or walls, flow-type installation slots for working with pipelines, and an easy, quick installation process.

Featured Applications

- For thermal power generation, the ultra-low dissolved oxygen levels in boiler feedwater and wastewater must be constantly checked to keep equipment from rusting.

- High-end fermentation includes precise control of biopharmaceuticals’ low dissolved oxygen content and precise fermentation processes to improve the quality of the final product.

- Pure water system: ultrapure water and electronic grade pure water are checked for dissolved oxygen to make sure the water is pure.

- Among the other situations that need very accurate measurements of dissolved oxygen are environmental tracking with very low emissions, chemical precision reactions, and others.

Daily maintenance and precautions

Maintenance points

- Electrode maintenance: Calibrate regularly (1-3 months), clean with neutral detergent when pollution is severe, and avoid using strong acids and alkalis; When not in use for a long time, it needs to be soaked in a specialized protective solution.

- Instrument maintenance: Keep the casing clean and avoid direct sunlight and corrosive environments; Check the relay contacts and wiring terminals once a year to prevent oxidation.

- Cable maintenance: Avoid pulling or bending cables. Special shielded wires should be used to extend cables, and the length should not exceed 30 meters.

Safety precautions

- Before installation and wiring, experts must unplug and turn off the power to avoid getting shocked.

- When connecting a relay to high-power equipment, use an extra relay to protect against contact overload damage.

- To keep the internal parts from getting damaged, the temperature must be kept between 130 and 150 degrees Celsius during electrode disinfection.

- To measure ultra-low dissolved oxygen, the sample must not have any bubbles and must flow steadily.

Technical Support

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 7 portable combustion analyzer Tested

The A20DO-PPB online dissolved oxygen controller is tailored for ultra-low dissolved oxygen scenarios with “PPB level precision, wide temperature adaptation, stability and reliability” as its core. From precision sensing configuration to intelligent operation design, from adaptation to harsh working conditions to convenient maintenance experience, we fully meet the core requirements of high-end industrial monitoring. Paired with PPB grade specialized electrodes and flow channels, a complete ultra-low dissolved oxygen monitoring solution is formed to assist users in controlling key water quality parameters and ensuring process stability.

We provide professional selection guidance, installation support, and after-sales service. If you need technical consultation or accessory procurement, please feel free to contact us at any time to make water quality monitoring more efficient and worry free!

Request a Quote

.png)