Sino-inst’s KSSS Series Conductivity electrode are designed to check the quality of water even when things are rough. They have two cylinders and are composed of 316L stainless steel. These sensors can work in temperatures up to 120°C and don’t rust in most liquids, with the exception of hydrofluoric acid. They give dependable and accurate conductivity readings that may be used online, even in tough industrial applications. The KSSS Series performs a great job of keeping pollution out. It can work with a lot of different levels of conductivity since it has huge platinum electrodes and a temperature compensation that can be modified.

★★★★★

Core Product Parameters

| Model | Cell Constant | Measurement Range | Temperature Resistance | Pressure Resistance | Installation Size |

|---|---|---|---|---|---|

| KSSS0.01 | 0.01±0.02 | 0.05μS/cm – 10μS/cm | 0~120℃ | 0.5Mpa | 1/2 NPT Thread |

| KSSS0.1 | 0.1±0.02 | 0.05μS/cm – 10μS/cm | 0~120℃ | 0.5Mpa | 1/2 NPT Thread |

| KSSS1.0 | 1±0.2 | 2μS/cm – 2000μS/cm | 0~120℃ | 0.5Mpa | 1/2 NPT Thread |

| KSSS10.0 | 10±2 | 2mS/cm – 200mS/cm | 0~120℃ | 0.5Mpa | 1/2 NPT Thread |

Features

Specifications

| Parameter Category | Specific Specifications |

|---|---|

| temperature compensation | NTC10K |

| Conductivity cell constant | 0.1±0.02 |

| heat-resistant | 0—120℃ |

| pressure resistance | 0.5Mpa |

| measurement range | 0.2us/cm—200us/cm |

| Wiring Instructions | Electrical wire (white black) Temperature wire (red yellow) |

Core Highlights

- It is made of 316L stainless steel, which can naturally oxidize to create a chemical passivation layer. It also doesn’t react with a lot of liquids, save for fluorinated acids. The large-area platinum structure design makes it even stronger at withstanding strong acids, bases, and pollutants, which makes it perfect for measuring needs in certain fields.

- The fixed conductivity cell constant has a high control accuracy of ± 0.02 and comes with a number of optional temperature adjustment elements that assist make sure that temperature doesn’t affect measurement findings. No matter what the working conditions are, this means that the data is correct and trustworthy.

- The low conductivity area is part of the measurement range, which makes it useful in many different scenarios. It is quite beneficial for duties that require a lot of accuracy, like checking the quality of clean water and keeping an eye on the environment. It can also be used to look at different samples of low-conductivity water from factories.

Featured Applications

- Ultra-Pure High-Temp Water Monitoring: KSSS0.01 (0.05μS/cm – 10μS/cm) suits ultra-pure water analysis in high-temperature processes (e.g., pharmaceutical sterilization, semiconductor manufacturing).

- High-Temp Pure Water Testing: KSSS0.1 (0.05μS/cm – 10μS/cm) is ideal for environmental monitoring and high-temperature pure water treatment (e.g., boiler feedwater).

- General High-Temp Water Monitoring: KSSS1.0 (2μS/cm – 2000μS/cm) fits high-temperature industrial circulating water, conductometric titration in chemical experiments, and hot tap water systems.

- High-Conductivity High-Temp Media: KSSS10.0 (2mS/cm – 200mS/cm) excels in monitoring high-salinity hot water, industrial wastewater (e.g., chemical, printing, dyeing), and high-temperature concentrated solutions.

Installation and operation points

Installation specifications

- After opening the box, check whether there is any mechanical damage to the electrode body to ensure that there is no damage before installation.

- Choose matching electrode protective sleeves or cable heads for fixation, and seal the interface properly; The connection between the electrode wire and the electrode is not waterproof, and additional waterproof protection is required to avoid water damage.

- The installation location should be selected in an area with stable water flow, no bubbles, and no severe turbulence to ensure that the electrodes fully contact the water sample and reduce measurement errors.

Usage and maintenance

- Storage: It should be kept in a dry place when not in use for a long time to avoid damage from water or harmful gases.

- Cleaning: Clean the electrode’s surface regularly to get rid of dirt and other particles. Cleansers and warm water or alcohol should be used to wash away organic pollution. Precipitates that are not organic should be soaked in 10% citric acid. First, clean it and then rinse it with pure water.

- Calibration: To make sure the measurement is accurate, electrode constant calibration can be done either by making a standard calibration solution or by measuring the same solution as a known constant electrode.

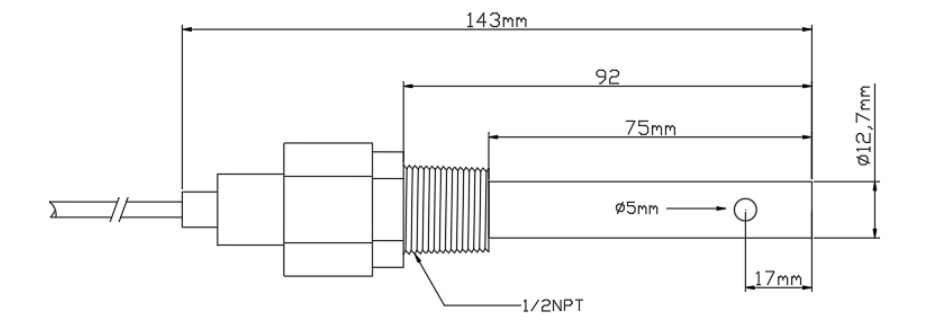

Electrode diagram illustration

Technical Support

Top 6 Industrial Gas Analyzers Manufacturers 2025

6 Best Industrial Gas Detector Manufacturers in the World

9 Best Portable Carbon Dioxide Detector 2025 – Complete Buying Guide

Top 7 portable combustion analyzer Tested

The Sino-inst KSSS Series Conductivity electrode are great for keeping an eye on the quality of difficult industrial water since they can tolerate high temperatures, resist corrosion, and give you accurate readings. There are four types of these that span all conductivity levels. They can also be made to work in high temperatures, with caustic materials, and to stop pollution.

You can trust Sino-inst to give you monitoring solutions that are trustworthy, easy to use, and work under tough conditions. If you need help picking something out or have a technical problem, please get in touch with our experts right away!

Request a Quote

.png)