The “stable tool” GRT1130 pH electrode works effectively in high-viscosity, clog-prone conditions. When working with thick suspensions, emulsions, and protein-rich thick liquids, ordinary electrodes often have interface blockage, hard maintenance, and poor adaptability. Disassembling and washing objects reduces efficiency, and viscous medium causes data drift. A solid gel dielectric and two-point ceramic core liquid contact prevent sticking and maintenance. Standard universal interface, double sheath adaption, different lengths. This allows it to monitor complex media in environmental protection, chemical manufacture, electroplating, and other industries using foreign electrodes. It also makes viscous measurements painless and stable.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-100℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

Core strength

- Anti blocking and anti sticking without jamming: two-point ceramic core liquid interface+solid gel dielectric, designed for viscous media, suspended particles, proteins, etc. are not easy to stick and block, and there is no worry about long-term online

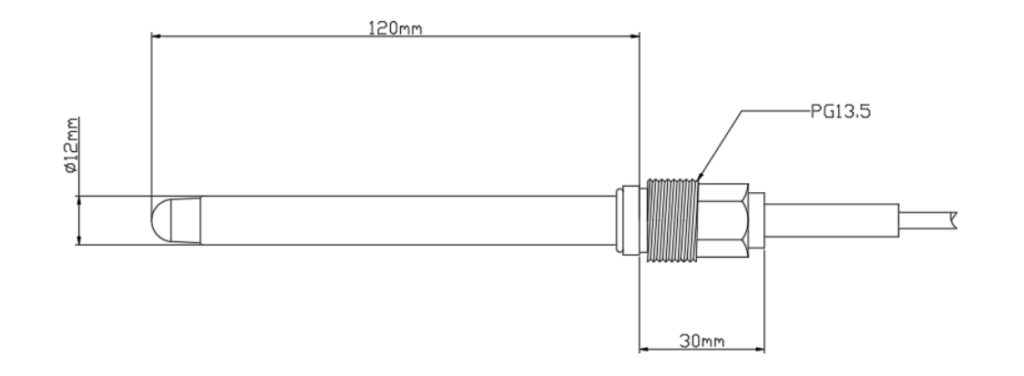

- Flexible and versatile adaptation: 120/150/200/250/300mm with multiple lengths to choose from, paired with stainless steel/PP double sleeves, suitable for different installation depths and medium characteristics

- Universal and easy to replace: standard PG13.5 threaded socket, can be directly exchanged with foreign electrodes, and new and old equipment docking does not require additional modification

- Wide temperature and pressure resistance adaptation: 0-100 ℃ working temperature, 0-0.3Mpa pressure resistance design, capable of withstanding temperature and pressure fluctuations in industrial conditions without failure

- Accurate and stable measurement: 0-14 full range coverage, zero potential of 7 ± 0.5mV, theoretical percentage slope ≥ 95%, small data drift, fast response

Adaptation scenario:

- Online monitoring of sewage treatment: continuous pH monitoring of industrial wastewater and biochemical treatment wastewater, anti blocking design to deal with suspended impurities in water, and dual protective sleeves suitable for different corrosive environments;

- Application in the electroplating industry: monitoring of plating solution, online monitoring of chromium removal process, resistance to medium impurity erosion, and optional length to adapt to different plating tank depths;

- Production of viscous media: pH measurement of viscous liquids such as pulp, starch, mud, sugar, etc., with anti sticking and anti blocking properties to avoid medium adhesion and ensure continuous measurement;

- Multi scenario adaptation in the chemical industry: monitoring complex media in industries such as chemical drugs, dyes, and mining, combining multiple lengths and double sheaths to adapt to different installation requirements such as pipelines and containers;

Maintenance

- Daily cleaning: Rinse the electrode with distilled water before and after measurement, gently absorb moisture with filter paper to avoid residue of viscous media;Deep cleaning once a week to clear the liquid interface;

- Sediment treatment: When the glass film appears semi transparent or adhered, soak it in dilute hydrochloric acid for 5-10 minutes, rinse with clean water, and do not scratch it with hard objects;

- Idle storage: After washing, put on a protective cover containing 3.3Mol/L KCL solution and place it in a dry and ventilated place. Dry storage is strictly prohibited from causing the sensitive film to fail;

- Regular calibration: It is recommended to calibrate once a week with standard calibration solution to ensure measurement accuracy; In scenarios with high levels of viscous media or impurities, calibration can be shortened to every 3-4 days;

- Taboo: Avoid long-term immersion in distilled water, protein solutions, or acidic chloride solutions, stay away from organic silicon oils and fats, and prevent electrode performance degradation.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

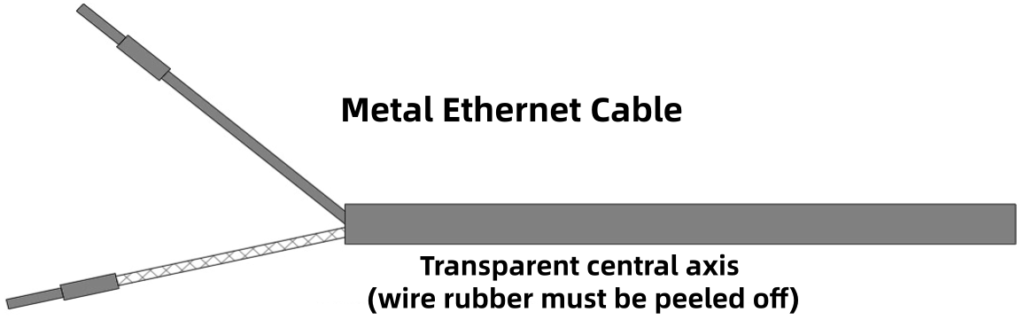

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1130 pH electrode, with its core advantages of anti clogging, anti sticking, maintenance free, and high adaptability, has become a reliable choice for viscous media and complex industrial conditions. Multiple lengths and dual protective sleeves are suitable for different installation needs. The standard thread supports the exchange of foreign electrodes, which not only solves the pain points of ordinary electrodes being easily blocked and difficult to maintain in viscous media, but also reduces the cost of replacing imported electrodes.

Consultation now provides exclusive selection solutions, installation guidance, and maintenance skills, allowing complex media pH measurement to overcome blockages and adaptation difficulties, and helping to efficiently operate production processes and accurately implement quality control!

Request a Quote

.png)