The GRT1120P-AS7 ORP sensor is a “multi energy adaptive monitor”for circuit boards and chromium containing wastewater treatment!Do we often encounter problems such as mismatched interfaces,inappropriate when detecting the oxidation-reduction potential of this type of wastewater?Ordinary electrodes either have a single interface that is difficult to replace, or have a fixed length that is poorly adapted, and it is also troublesome to supplement electrolytes. And it is equipped with a dual interface design, optional length, and a platinum silver chloride composite electrode structure. It does not require electrolyte replenishment and has strong stability, perfectly adapting to specific wastewater treatment scenarios, making potential monitoring both accurate and flexible.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| ORP Range | -1999—1999mv |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Electric potential | 245-270mv |

| Stability | ±8mv/24h |

Core product advantages

- Platinum silver chloride composite structure with online potential detection accuracy

- Suitable for normal working conditions from 0-60 ℃, without the need for additional temperature adjustment

- Equipped with 0.3Mpa pressure resistance, it is not afraid of pressure fluctuations in wastewater treatment

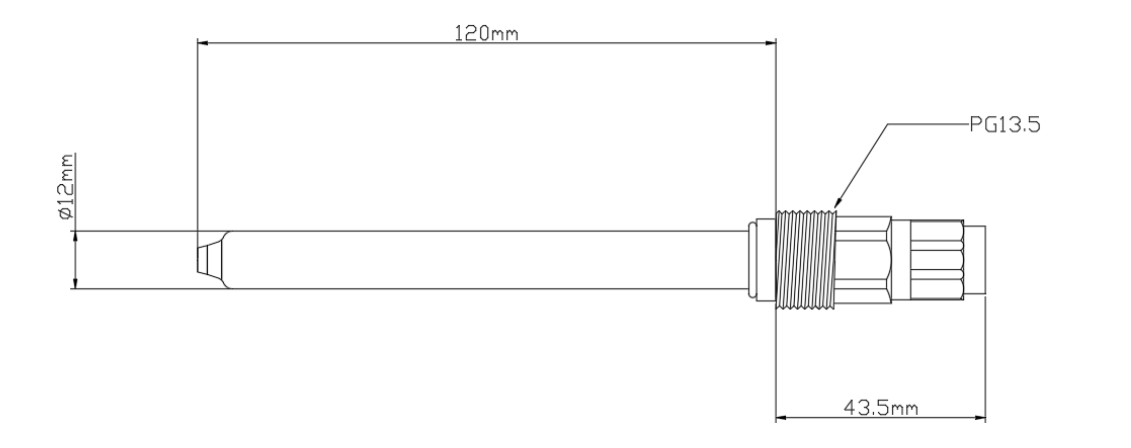

- PG13.5 standard thread, easy installation of pipes and protective sleeves

- Cleaning platinum plates is easy, and oil stains and organic matter can be easily removed

- Specializes in circuit boards, chromium containing wastewater, and scene adaptation without stepping on lightning

Accurately adapting to the scene

- Monitoring of PCB wastewater treatment: Suitable for various stages of PCB production wastewater, real-time capture of oxidation-reduction potential changes, intuitive feedback on treatment effects, providing data support for process adjustments, and ensuring wastewater meets standards.

- Special monitoring of chromium containing wastewater: covering the entire process of oxidation-reduction reaction of chromium containing wastewater, accurately monitoring potential fluctuations, helping to control the progress of chromium removal reaction, and avoiding discharge exceeding standards caused by incomplete treatment.

- Multiple installation environment adaptation: Different lengths can be selected, with shallow pipelines ranging from 120/150mm and deep containers ranging from 200-300mm. Equipped with dual interfaces, it can adapt to various industrial site layouts such as pipeline installation and container wall mounting.

- Conventional industrial wastewater monitoring: suitable for several categories of industrial wastewater within the temperature range of 0-60 ℃, necessitating accurate measurement of oxidation-reduction potential to comply with environmental control standards.

Usage and Maintenance Guide

- Before you take a measurement, make sure the reference joint and platinum sensing area are both fully underwater in the sample. Use a clean cloth to wipe the silver surface to get rid of any dirt that isn’t stuck.

- Cleaning Instructions:

- Gently wipe the silver piece with a cloth soaked in alcohol or acetone to get rid of oil stains.

- If you have biological materials that won’t dissolve, clean them with 30–50% hydrochloric acid and then rinse them with distilled water.

- Only use soft things! Platinum surfaces can be scratched very easily.

- Notes for Calibration:

- Use a newly made pH 4.00 quinhydrone-saturated buffer solution. It can only be used for two days.

- To keep things correct, you should calibrate them often (every 2 to 4 weeks for wastewater cases).

- Electrodes should be washed with pure water and stored in a clean, dry place when not in use. Don’t soak it in pure water or other corrosive liquids for a long time.

- Water Protection: The part where the sensor wire connects to the body can’t get wet. Wrap it with waterproof tape or use a waterproof junction box to keep wetness out.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and sensor body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

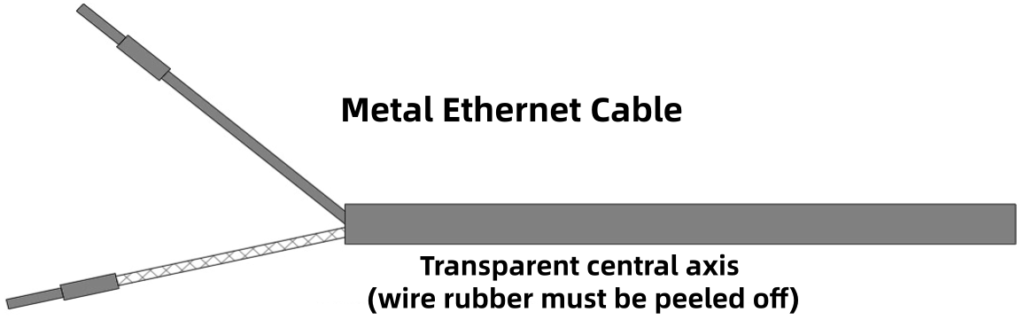

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1120P-AS7 ORP sensor,with its flexible adaptation of dual interfaces and multiple lengths,coupled with its core advantages of precision,stability,and maintenance free,perfectly solves the monitoring pain points in circuit boards and chromium containing wastewater treatment. Whether it’s on-site equipment docking, imported electrode replacement, or adaptation to different installation environments, it can easily handle them and stably output reliable data without complex operations.

Consultation now provides exclusive selection advice, installation guidance, and standard liquid configuration tutorials, allowing for the elimination of adaptation difficulties in redox potential monitoring and helping industrial wastewater treatment operate efficiently and meet standards!

Request a Quote

.png)