The global demand for precision air quality monitoring and industrial safety equipment has never been higher. As we approach 2026, the market for electrochemical gas sensor manufacturers is evolving rapidly, driven by stricter environmental regulations, the rise of the hydrogen economy, and the need for smart city infrastructure. These sensors are the critical components that detect toxic gases, oxygen levels, and combustible elements in real-time, ensuring safety across sectors from petrochemicals to residential automation.

Choosing the right partner for your sensing needs is crucial. Whether you are an OEM looking to integrate modules into your devices or a facility manager needing reliable replacement parts, understanding the landscape of electrochemical gas sensor manufacturers is the first step. This guide profiles the top players setting the standard for innovation, reliability, and cost-effectiveness in the coming year.

- 1. Market Outlook: The Future of Gas Sensing in 2026

- 2. Sino-Inst: The Professional Choice for Integrated Solutions

- 3. Honeywell (City Technology): The Global Standard

- 4. Alphasense: UK Innovation in Air Quality

- 5. Figaro Engineering: Pioneers in Lead-Free Technology

- 6. Membrapor: Swiss Precision for High-End Applications

- 7. SGX Sensortech: Industrial Safety Specialists

- 8. Summary Comparison Table

- 9. Buying Guide: How to Select an Electrochemical Sensor

- 10. Frequently Asked Questions (FAQs)

- 11. References

1. Market Outlook: The Future of Gas Sensing in 2026

The landscape for electrochemical gas sensor manufacturers is shifting towards miniaturization, lower power consumption, and digital integration. By 2026, industry analysts predict a significant surge in demand for sensors capable of detecting hydrogen (H2) due to the clean energy transition, as well as ultra-sensitive detectors for Volatile Organic Compounds (VOCs) in urban environments.

Leading electrochemical gas sensor manufacturers are investing heavily in solid-electrolyte technologies and smart modules that offer “plug-and-play” capabilities. This reduces the burden on end-users to perform complex calibrations. Furthermore, the integration of IoT (Internet of Things) means that modern gas sensors must not only detect hazards but also transmit data seamlessly to central monitoring systems.

2. Sino-Inst: The Professional Choice for Integrated Solutions

When discussing versatile and customer-centric electrochemical gas sensor manufacturers, Sino-Inst stands out as a premier supplier of industrial process and analytical instruments. Unlike traditional manufacturers who may only supply the raw component, Sino-Inst focuses on providing complete measurement and analysis solutions.

Company Snapshot

Sino-Inst is a professional supplier of industrial process and analytical instruments, including gas detectors, gas analyzers, dust detectors, mass flow controllers, and dust monitors. They are dedicated to helping clients obtain reliable measurement and analysis solutions while saving procurement costs. With a strong focus on flexibility, customized products and OEM services are available, making them a trusted partner for diverse industrial needs.

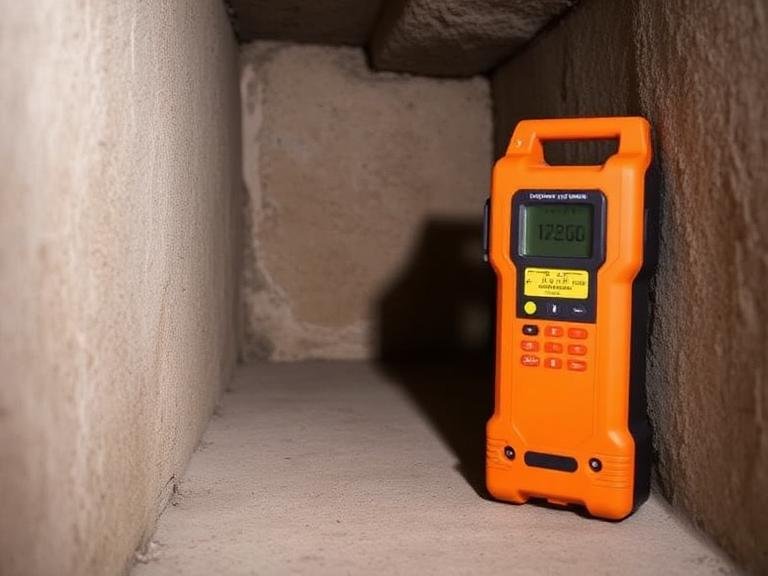

Featured Product: 800 Series Gas Sensor Module

Sino-Inst has developed the 800 Series, a module that exemplifies the modern trend towards integration and ease of use. This product is designed to bridge the gap between raw sensor technology and user-friendly application.

Key Features of the 800 Series:

- Compact Design: The whole machine is small in size and light in weight, making it ideal for portable devices and tight installation spaces.

- Multi-Principle Compatibility: Professional sensors can be equipped based on electrochemistry, catalytic combustion, infrared principle, and thermal conductivity principle, offering unmatched versatility.

- Performance: High precision, high resolution, and fast response times ensure safety and data accuracy.

- Safety First: Intrinsically safe circuit design allows for hot plug and unplug operations, critical for hazardous environments.

- Reliability: Features a data recovery function to eliminate worries caused by misoperation.

- Smart Calibration: Automatic temperature and humidity compensation function and accurate factory calibration mean there is no need to use calibration again immediately upon installation.

- Connectivity: Simultaneous output of analog voltage or current and serial port makes it convenient for customer debugging and use.

- User-Friendly: The most sophisticated circuit design and manufacturing process results in complex production but simple use. It can be connected to a computer for communication and self-calibration.

- Maintenance: Built-in zero point fine-tuning function for convenient reference data selection.

- Energy Efficient: A low-power product that can be powered by a mobile power supply, widely used in analyzer instruments, atmosphere monitoring, and environmental drone monitoring.

For businesses seeking a partner that combines manufacturing capability with solution-oriented service, Sino-Inst is a top contender among electrochemical gas sensor manufacturers for 2026.

3. Honeywell (City Technology): The Global Standard

No list of electrochemical gas sensor manufacturers is complete without mentioning Honeywell, specifically their City Technology brand. They have long been the gold standard in the industry, producing millions of sensors annually.

Technology and Innovation

Honeywell’s sensors are renowned for their robustness in harsh environments. Their “Series 4” sensors are the industry footprint standard for portable gas detectors. Moving into 2026, Honeywell is pushing boundaries with their “iSeries” digital sensors, which provide predictive maintenance data, telling the user when a sensor is reaching the end of its life before it fails.

Key Strengths

- Massive Portfolio: They offer sensors for virtually every detectable gas, from Carbon Monoxide (CO) and Hydrogen Sulfide (H2S) to exotic gases.

- Reliability: Proven track record in life-safety applications where failure is not an option.

- Global Support: Extensive distribution and support network worldwide.

4. Alphasense: UK Innovation in Air Quality

Based in the United Kingdom, Alphasense has carved out a significant niche as one of the most innovative electrochemical gas sensor manufacturers, particularly in the environmental air quality monitoring sector.

Specialized Sensors

Alphasense is famous for its “B-Series” sensors designed for low-ppb (parts per billion) detection, which is essential for urban air quality networks measuring NO2, O3, and SO2. As cities become “smarter” in 2026, the demand for Alphasense’s high-sensitivity electrochemical sensors is expected to skyrocket.

Product Highlights

- A-Series and B-Series: High-performance sensors for industrial and environmental applications.

- PID Sensors: While known for electrochemical, they also lead in Photoionization Detectors (PID) for VOCs.

- Quality Control: Alphasense is known for rigorous individual testing of sensors, providing specific calibration data for each unit sold.

5. Figaro Engineering: Pioneers in Lead-Free Technology

Japan’s Figaro Engineering Inc. is a legend in the gas sensing world, originally famous for their MOS (Metal Oxide Semiconductor) sensors. However, they have become a major player among electrochemical gas sensor manufacturers with their KE-series oxygen sensors and their newer TGS models.

Sustainability Focus

One of Figaro’s major contributions for the 2026 market is the development of lead-free galvanic cell oxygen sensors. Traditional oxygen sensors often rely on lead, which poses disposal and regulatory issues. Figaro’s lead-free options are future-proof against tightening environmental regulations like RoHS in Europe.

Key Products

- KE-Series: Oxygen sensors known for long life (up to 5-10 years) and chemical stability.

- TGS5000 Series: Compact, battery-operable electrochemical sensors for CO detection, ideal for residential fire alarms.

6. Membrapor: Swiss Precision for High-End Applications

When high precision is the priority, Membrapor is often the manufacturer of choice. Based in Switzerland, this company focuses on high-performance sensors for niche and demanding applications.

The 4-Electrode Advantage

Membrapor is one of the few electrochemical gas sensor manufacturers that specializes in 4-electrode sensors. These sensors include an auxiliary electrode that compensates for zero-current drift, allowing for extremely accurate measurements even in fluctuating temperatures. This makes them perfect for emissions monitoring and breath analysis.

Target Markets

- Emissions Control: Monitoring stack gases and combustion efficiency.

- Medical: Breath analysis devices.

- Hydrogen Economy: Specialized H2 sensors that can operate without interference from other gases.

7. SGX Sensortech: Industrial Safety Specialists

SGX Sensortech (part of the Amphenol family) has a strong heritage in industrial safety. Formerly a division of e2v, they have decades of experience in producing sensors that survive the toughest conditions, such as mining and oil & gas exploration.

Rugged reliability

SGX is a top choice for intrinsic safety applications. Their electrochemical sensors are designed to withstand high humidity, pressure changes, and mechanical shock. For 2026, they are expanding their range of low-power sensors for wireless industrial IoT (IIoT) applications.

Core Offerings

- Industrial Safety: CO, H2S, O2, and NH3 sensors for personal gas monitors.

- Mining: Robust sensors capable of functioning deep underground.

- Automotive: Air quality sensors for cabin comfort and safety.

8. Summary Comparison Table

To help you decide which of the top electrochemical gas sensor manufacturers fits your needs, we have compiled this comparison of their primary strengths and target markets for 2026.

| Manufacturer | Headquarters | Primary Strengths | Key Product Lines | Best Application |

|---|---|---|---|---|

| Sino-Inst | China | Integrated Solutions, Cost-Effectiveness, Customization | 800 Series Modules, OEM Services | Industrial Process, System Integration, Drones |

| Honeywell | USA / UK | Global Scale, Reliability, Wide Range | Series 4, iSeries, City Tech | General Industrial Safety, Portable Detectors |

| Alphasense | UK | High Sensitivity, Environmental Focus | B-Series (ppb level), A-Series | Air Quality Monitoring, Urban Pollution |

| Figaro | Japan | Long Life, Lead-Free Technology | KE-Series (Oxygen), TGS Series | Residential Alarms, Medical Oxygen |

| Membrapor | Switzerland | High Precision, 4-Electrode Tech | Compact, Slim, and Standard sizes | Emissions, Breath Analysis, Lab Analysis |

| SGX Sensortech | Switzerland / China | Ruggedness, Hazardous Areas | SGX Series, IR and Pellistor combos | Mining, Oil & Gas, Heavy Industry |

9. Buying Guide: How to Select an Electrochemical Sensor

Selecting the right component from the various electrochemical gas sensor manufacturers requires technical due diligence. Here are the critical factors to consider:

1. Target Gas and Cross-Sensitivity

Electrochemical sensors are generally specific to a target gas, but cross-sensitivity is a common issue. For example, a CO sensor might react to Hydrogen. If your environment has mixed gases (like a battery charging room), ensure you choose a sensor with a filter or an electrode design that minimizes this interference. Manufacturers like Membrapor and Sino-Inst offer detailed cross-sensitivity data.

2. Measurement Range and Resolution

Do you need to detect a massive leak (percent volume) or a trace amount (parts per billion)?

Industrial Safety: Usually requires ppm range (e.g., 0-100 ppm H2S).

Air Quality: Requires ppb range (e.g., 0-200 ppb NO2). Alphasense and Membrapor excel here.

3. Environmental Conditions

Electrochemical sensors contain a liquid electrolyte. Extreme heat can dry them out, while extreme cold can freeze them. If your application is outdoors or in a drone (like those supported by Sino-Inst’s 800 series), ensure the operating temperature range matches your environment (-40°C to +50°C is standard, but check specifics).

4. Form Factor and Integration

If you are building a compact portable device, the physical size matters. The “Series 4” size is a standard, but many electrochemical gas sensor manufacturers now offer “mini” or ultra-thin profiles. Additionally, consider if you want a raw sensor (requiring your own circuit design) or a pre-calibrated module like the Sino-Inst 800 Series, which outputs a ready-to-use digital signal.

10. Frequently Asked Questions (FAQs)

What is the lifespan of an electrochemical gas sensor?

Typically, electrochemical sensors last between 2 to 3 years. However, high-quality oxygen sensors (like Figaro’s galvanic cells) can last up to 5-10 years. Exposure to high concentrations of the target gas or poisoning agents can shorten this lifespan.

Can I use sensors from different manufacturers in the same device?

Yes, provided the pin configuration and electrical characteristics match. Many electrochemical gas sensor manufacturers adhere to industry-standard sizes (like the 20mm diameter Series 4), making them interchangeable. However, bias voltage and gain settings on your circuit board may need adjustment.

Why do I need to calibrate my sensor?

Sensors drift over time due to electrolyte evaporation and catalyst degradation. Regular calibration ensures accuracy. However, modules like the Sino-Inst 800 Series come with factory calibration and smart compensation, reducing the frequency and complexity of field calibration.

What are the advantages of using a pre-calibrated module?

Using a module saves significant R&D time. Instead of designing a potentiostat circuit and writing algorithms for temperature compensation, you simply plug in the module and read the data via UART or analog output. This is ideal for rapid prototyping and companies without deep in-house electrochemical expertise.

11. References

- Market Research Future. (2025). Global Gas Sensor Market Research Report – Forecast to 2030.

- Honeywell Analytics. (2024). Technical Handbook of Electrochemical Sensors.

- Alphasense. (2024). Air Quality Sensor Application Notes.

.png)