GRT1320W pH electrode is a reliable partner for high temperature conditions! Disinfection and sterilization in biotechnology, high-temperature processes in the pharmaceutical industry, and boiling processes in beer brewing, ordinary electrodes either cannot withstand high temperatures and are prone to failure, or are difficult to maintain and have poor adaptability. Replacing imported electrodes is also costly. And it is equipped with high-temperature resistant solid dielectric and two-point ceramic core structure, which can withstand 130 ℃ disinfection and sterilization, no need to supplement dielectric and anti blocking, matched with multi length, double sheath adaptation and standard threaded interface, perfectly covering the high-temperature needs of industries such as biology, pharmaceuticals, food and beverage, making high-temperature environment measurement accurate and worry free.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 pH |

| Theoretical percentage slope | ≥ 95 |

| Zero potential | 7±0.5 |

| Temperature Range | 0-130℃ |

| Pressure Range | 0—0.3 |

| Thermistor | PT1000 (customizable: PT100/10K/PT1000/30K/2.252K) |

Main Benefits

- High temperature resistance and strong sterilization: can withstand disinfection and sterilization at 130 ℃, stable measurement within the range of 0-95 ℃, suitable for the entire process of high temperature technology

- Maintenance free and cost saving: High temperature resistant solid dielectric pre filled molding, no need for replenishment, two-point ceramic core liquid interface anti blocking, minimal maintenance required

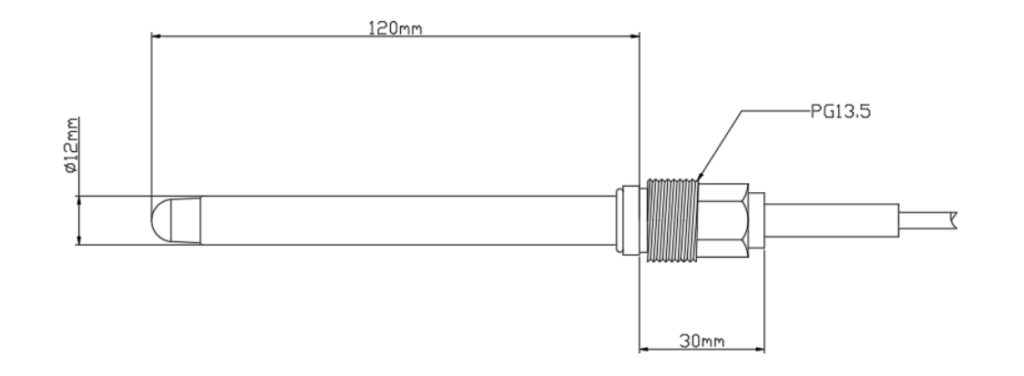

- Flexible adaptability: Available in multiple lengths of 120/150/200/250/300mm, with stainless steel/PP double sheath matching, suitable for different installation scenarios

- Universal and easy to replace: standard PG13.5 threaded socket, can be directly exchanged with foreign electrodes, replacing old equipment without additional modification

- Pressure resistant and anti reverse pressure: 0-0.3Mpa pressure resistant design, no restrictions on reverse pressure usage, suitable for high-pressure and high-temperature collaborative working conditions

- Strong industry adaptability: designed specifically for the biotechnology, pharmaceutical, beer, food and beverage industries, matching high-temperature production process requirements

Where Can You Use It?

- Bioengineering: High temperature disinfection and pH monitoring of production processes such as amino acids, blood products, genes, insulin, interferon, etc., with resistance to repeated sterilization without failure

- Pharmaceutical industry: Production of antibiotics, vitamins, citric acid and other drugs, with precise pH control in the sterilization process to meet the quality requirements of the pharmaceutical industry

- Beer brewing: the entire process of saccharification, boiling, fermentation, filling, etc., covering pH measurement of cold wort, pre/post filtration liquid, deoxygenated water and other media, suitable for high-temperature brewing technology

- Food and beverage: production of monosodium glutamate, soy sauce, dairy products, fruit juice, yeast, sugar, drinking water, etc., suitable for high-temperature sterilization process, in compliance with food hygiene standards

How to Use & Maintain It

- Before you take a reading, wash the sensor with pure or deionized water, and then use filter paper to dry it. Make sure that both the sensor bulb and joint are fully underwater in the liquid to keep the data correct and the pollutants out.

- Cleaning Tips: If the glass bulb has any sediment on it, soak it in a week hydrochloric acid solution for 5 to 10 minutes and then rinse it with pure water. Don’t scrape it with a strong brush; the delicate bulb will be hurt.

- Calibration: Do this once a week (more often for complex media like fermentation broth). Use fresh pH7.00 buffer solution for calibration, plus pH4.00 (acidic media) or pH10.00 (alkaline media) if needed. It only takes 5 minutes!

- Replacement tip: If the sensor still won’t calibrate after proper maintenance, it’s time to replace it—no need to waste time on repairs.

- Storage: When not in use, clean the electrode first, then store it in the protective cap filled with 3.3Mol/L KCL solution. Never leave it soaking in distilled water or expose it to silicone grease—this shortens its life.

- Waterproof Note: The wire connection isn’t waterproof! Wrap it with waterproof tape or use a dedicated junction box to prevent moisture damage (critical for wet production areas).

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Remove the electrode protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

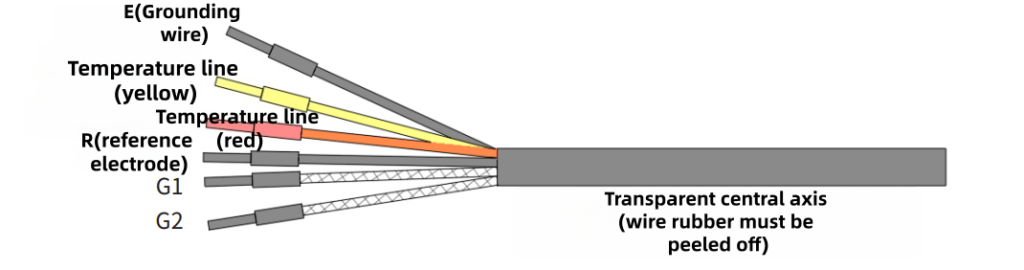

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1320W pH electrode has become a reliable choice for high-temperature processes in industries such as biology, pharmaceuticals, food and beverage due to its core advantages of high temperature sterilization resistance, maintenance free, and high adaptability. Multiple lengths and dual protective sleeves are suitable for different installation needs. The standard thread supports the exchange of foreign electrodes, which not only solves the pain point of ordinary electrodes not being heat-resistant, but also reduces the cost of replacing imported electrodes.

Consultation now provides exclusive selection solutions, high-temperature scenario usage tips, and one-on-one technical support, allowing high-temperature process pH measurement to bid farewell to failure and adaptation difficulties, and assisting in the efficient operation of production processes and precise implementation of quality control!

Request a Quote

.png)