The GRT1320PD differential pH sensor uses core differential technology and a wide temperature and range design to solve the problems that traditional pH sensors often have in extreme industrial situations, like when there are severe acid-base media, high-temperature organic solvents, and hydrocarbons. The GRT1320PD differential pH electrode has a wide range and temperature design, which is what solves these problems. Make it feasible to go beyond the bottleneck that comes with keeping an eye on harsh environments and provide measuring solutions that are both accurate and long-lasting for difficult working conditions in many fields.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | -2-14 pH |

| ORP Range | -1500—+1500mV |

| Zero potential | 7±0.5 |

| Temperature Range | -5—105℃ |

| Pressure Resistance | At 105 ℃, it is 4 bar |

Main Benefits

Differential three-electrode technology: replacing standard dual electrodes, lowering reference pollution, getting rid of closed-loop circulation, and making data more stable.

Adaptation over a very wide range: pH from 2 to 14 and ORP from -1500 to +1500 mV, which covers very acidic and basic situations

Very hot and very high pressure Tolerance: It can work at temperatures between -5 and 105 degrees Celsius and can handle 4 bars at 105 degrees Celsius. It is good for processes that happen at high temperatures.

Longer lifespan: 3/4″ plastic shell models can have their salt bridges replaced, which lowers the expense of using them for a long time.

Universal installation design: The PG13.5 threaded interface and protective sleeve may easily adapt to different operating situations.

Where Can You Use It?

- Chemical high-temperature reaction scenario: adapted to acid-base synthesis, organic solvent high-temperature preparation and other processes, capable of withstanding high temperatures of 105 ℃ and pressures of 4 bar, and accurately monitoring pH/ORP changes under extreme temperatures;

- Strong corrosive medium monitoring: It can directly measure high concentration acidic and alkaline substances, as well as chemical media such as alcohol, hydrocarbons, aromatic compounds, etc., avoiding the problems of corrosion and pollution of traditional electrodes;

- Advanced treatment of industrial wastewater: for harsh wastewater with high acidity, alkalinity, and residual solvents, tracking key parameters such as neutralization reaction and biochemical treatment to help optimize the process;

- Chemical and special material production: can be used to control pH/ORP in high-precision production processes like making lipids and ketones. It meets strict quality standards with a pH sensitivity of ± 0.01.

Installation and usage guide

Installation key points

- Open box inspection: Confirm that there is no mechanical damage to the sensitive bulb. If there are bubbles, they can be removed by gently shaking vertically;

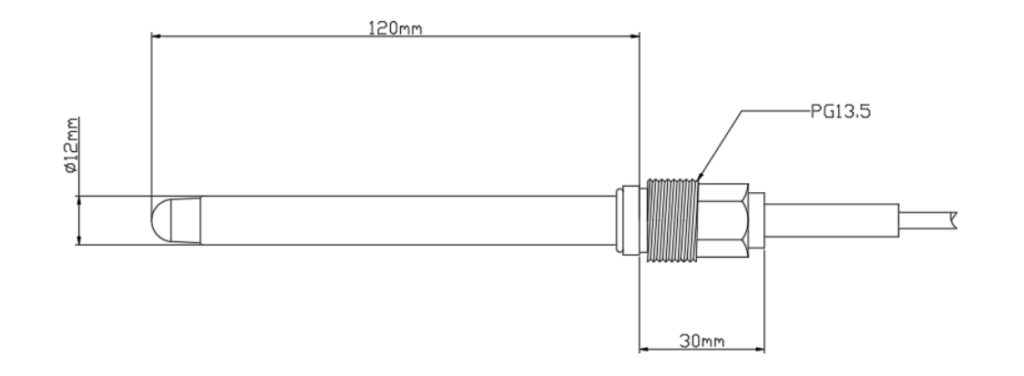

- Interface installation: PG13.5 threaded interface is used, matched with corresponding protective sleeve or cable head fixation to ensure stable installation;

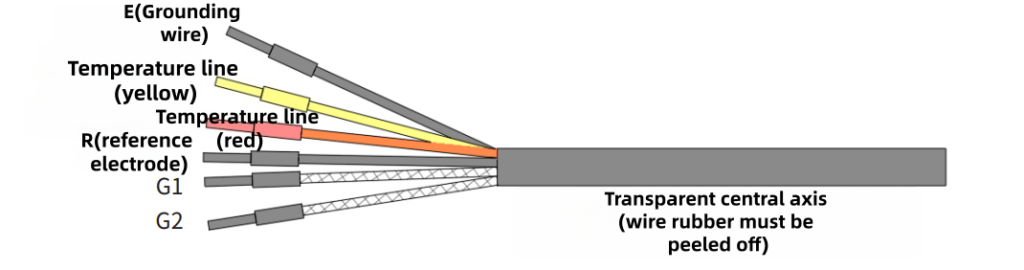

- Stripping specification: Peel off the metal wire layer, thoroughly remove the conductive black skin of the transparent central axis, and avoid signal interference;

- Waterproof protection: If the electrode wire connection is not waterproof, it needs to be sealed with sealant or waterproof joint to prevent moisture damage.

Maintenance

- Daily cleaning: Rinse the electrode with distilled water before and after measurement to remove residual media and avoid sediment adhesion;

- Idle storage: Cover with a protective cover containing 3.3mol/L KCL solution and store in a dry and ventilated environment to prevent sensitive bubbles from drying out;

- Salt bridge replacement: For the 3/4 “plastic shell model, follow the instructions and soak it in KCL solution for 24 hours before calibration;

- Calibration cycle: Calibrate once a month under normal working conditions, and shorten to once a week under high temperature and high pollution working conditions.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Remove the electrode protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1320PD differential pH electrode can work in a wide range of temperatures and ranges, is very accurate, and doesn’t get dirty easily. It can readily manage a wide range of tough work situations and problems, such as chemical reaction vessels that work at high temperatures and pressures, industrial wastewater treatment that is very corrosive, and fine chemical synthesis that is very acidic. The adjustable salt bridge architecture makes the sensor cheaper to use, while differential technology has fixed the primary difficulties with older sensors. You may install the PG13.5 universal interface in many different ways, which makes it a cheap solution to measure pH and ORP in very demanding industrial situations.

Request a Quote

.png)