The HF1120W pH sensor, with its special sensitive membrane and two-point ceramic core anti blocking structure, solves the problem of conventional pH electrodes being easily corroded and ineffective by fluoride ions in highly corrosive media containing hydrofluoric acid (HF).

It is specially designed for HF containing scenarios, with the advantages of maintenance free and high compatibility, and accurately adapts to pH monitoring in highly corrosive media, providing stable data support for process control and environmental compliance.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

| Thermistor | PT1000 (customizable: PT100/10K/PT1000/30K/2.252K) |

Core product advantages

HF resistant strong corrosion:

special sensitive film formula, resistant to fluoride ion erosion, with clear fluoride ion tolerance concentration at different pH levels (F ⁻<300ppm at pH 2, etc.), avoiding rapid failure of conventional electrodes;

Blocking prevention and maintenance free:

gel dielectric+two-point ceramic core liquid interface is suitable for corrosion media containing impurities, which is not easy to block and does not need to supplement dielectric, so the maintenance amount is small;

International universal compatibility:

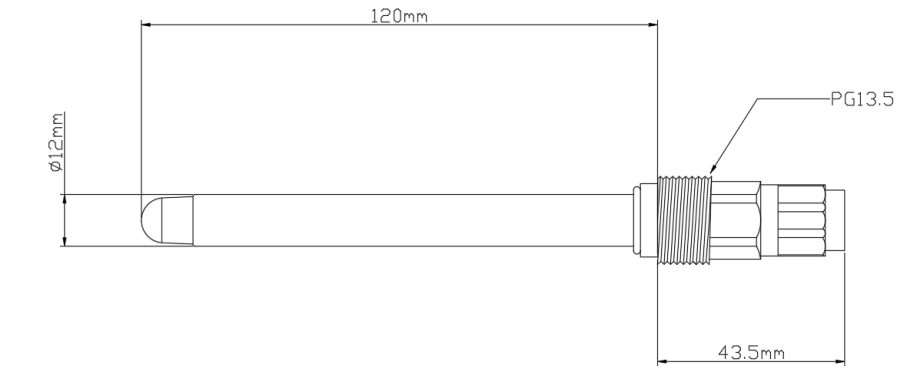

PG13.5 standard thread, can be directly exchanged with foreign sensors, supports PVC/PP sheath, suitable for different corrosion scenarios and imported equipment;

Flexible selection of multiple specifications:

120/150/200/250/300mm length options are available to meet different installation depths, ensuring that the electrode bulb and liquid junction are submerged in the measured liquid simultaneously.

Accurately adapting to the scene

- Keeping an eye on how fluorine chemicals are made: monitoring the pH of HF-containing reaction solutions and intermediates in real time in the fluorine chemical business. This is done in places that are very damaging, and it lets you make sure that the response process is very precise.

- Watching the electronic etching process: the HF etching solution’s pH (used to make electronics and circuit boards) is checked and the process is changed to keep the pH within the right range. If the pH is too high or too low, it could affect the product’s precision.

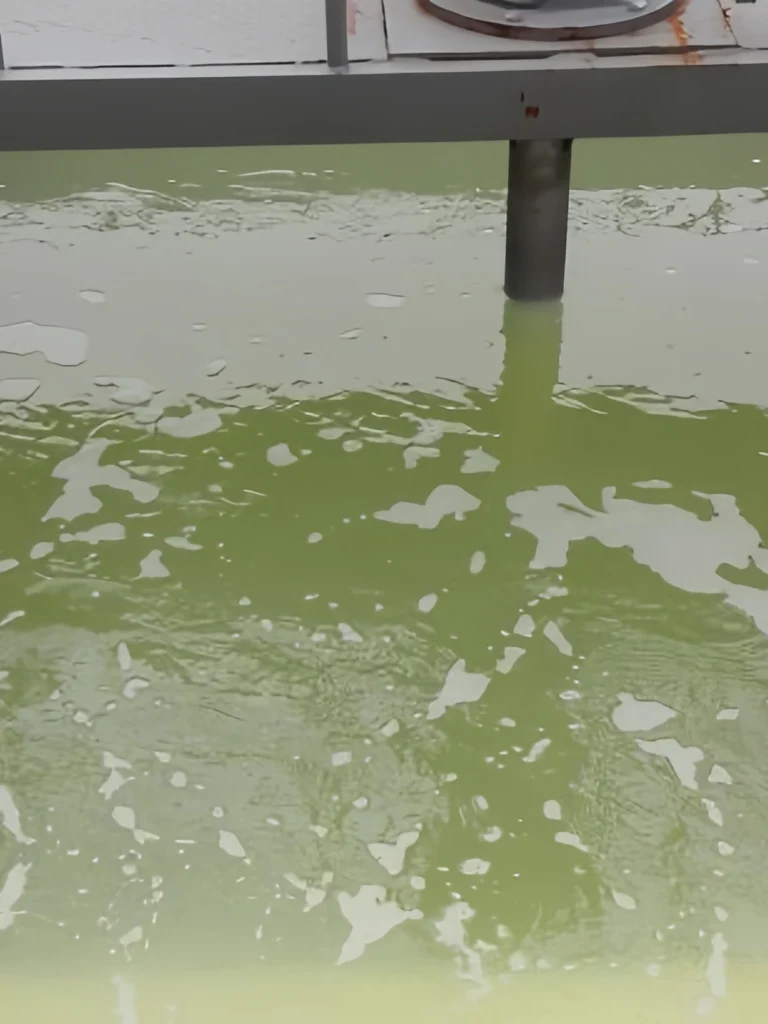

- HF-containing wastewater treatment: pH level monitoring in the treatment of industrial wastewater containing hydrofluoric acid (like waste liquids from chemicals, electronics, etc.) to make sure that acid-base neutralization is up to standard and to stop strongly corrosive wastewater from harming the environment.

- Pharmaceutical intermediate synthesis: pH monitoring of the intermediate synthesis reaction solutions that include HF in the pharmaceutical industry in order to meet the cleanliness detection standards of difficult corrosion situations while keeping the product good quality.

Usage and Maintenance Guide

- Before measurement, clean the sensor with distilled water and absorb the moisture to ensure that the bulb and the liquid junction are submerged in the measured liquid at the same time, avoiding impurities from entering and affecting the data;

- Soak in 3.3Mol/L KCL solution when idle, and avoid long-term immersion in distilled water, protein solution, or acidic chloride solution. Keep away from organic silicon oils and fats;

- Clean and calibrate once a week, wash the glass film sediment with dilute hydrochloric acid, and prohibit scratching the sensitive film with a hard brush;

- Strictly follow the HF concentration resistance specifications to avoid sensor damage caused by over concentration and over temperature conditions.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

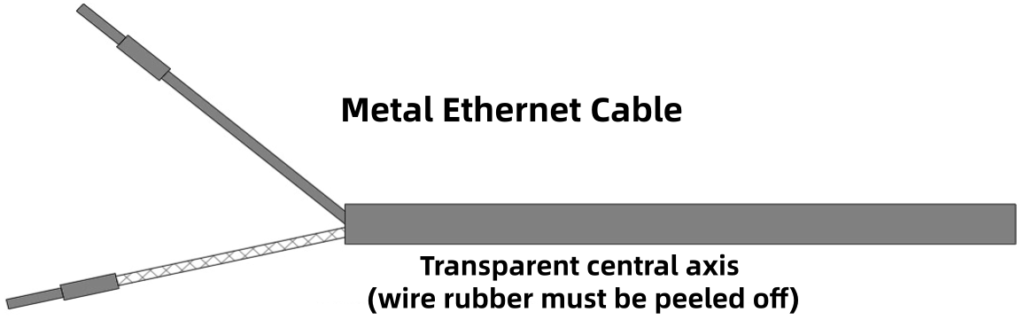

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

When the HF1120W pH electrode comes into contact with HF, it doesn’t corrode readily. It doesn’t need to be cleaned or serviced, and it doesn’t need to be cleared if it is blocked. This stops the problem of evaluating the pH of fluids that have hydrofluoric acid in them. It can handle particularly nasty rust while producing chemicals using fluorine, cutting electronics, and cleaning up dirty water. Its hard core performance delivers the essential information to make sure that environmental criteria are met and to make processes better. If you put electrodes in the right spot and take care of them, they will last longer and cost less to use.

Request a Quote

.png)